Documents

Datasheets

Download:Description

For General Industrial Filtration Applications

Seitz T series depth filter sheets were developed for coarse and clarifying filtration of many fluids in the food and beverage industry.The "T" stands for technical because these filter sheets are designed for general industrial filtration duties. T 120 through T 950 are specifically designed for clarifying filtration. With their positive ZETA potential, these depth filters contain a high adsorption capacity. T 1000 through T 5500 have no ZETA potential. This range of the T series is characterized by its open structure and is well suited for filtration of high suspended solids and viscous applications.

From the selection and quality control of raw materials to application of the latest production technologies, the T series filter sheets meet the highest quality standards.

| Features | Benefits |

| Homogenous and consistent media, available in multiple grades |

|

| Reduced density and high porosity media with low filtration resistance |

|

| Each individual filter sheet is laser etched with the sheet grade, batch number and production date. |

|

Specifications

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Main Constituents

| T 120, T 500, T 750, T 950, T 1000, T 1500, T 2100, T 3500 | cellulose, perlite |

| T 2600, T 5500 | cellulose |

Characterization

| Grade | Mass per Unit Area g/m2 | Thickness mm | Ash % | Water Permeability2 L/m2/min (gal/ft2/min) |

| T 120 | 900 | 2.8 | 43 | 213 (5.3) |

| T 500 | 850 | 2.7 | 38 | 465 (11.6) |

| T 750 | 850 | 2.7 | 40 | 565 (14.1) |

| T 950 | 850 | 2.8 | 40 | 1,700 (42.5) |

| T 1000 | 950 | 3.6 | 35 | 3,400 (85) |

| T 1500 | 850 | 3.7 | 33 | 7,285 (182.1) |

| T 2100 | 700 | 3.3 | 15 | 10,200 (255) |

| T 2600 | 700 | 2.9 | < 1 | 10,200 (255) |

| T 3500 | 888 | 4.6 | 15 | 12,750 (318.8) |

| T 5500 | 750 | 4.5 | < 1 | 25,500 (637.5) |

These figures have been determined in accordance with in-house test methods and the methods of the Technical /Analytical Work Group within the European Depth Filtration Association.

2The permeability was measured under test conditions with clean water at 20 °C (68 °F) and a Δp of 1 bar (14.5 psi).

Regeneration

T series filter sheets may be rinsed with clean water (in the forward or reverse3 direction) to increase throughput and to optimize economic efficiency. Optimal regeneration of filter sheets installed in a plate and frame filter may be achieved with serial rinses of warm water followed by hot water. An example protocol is shown below.- Rinse with warm water (60 °C / 140 °F) for 15 minutes

- Rinse with hot water (70 – 80 °C / 158 – 176 °F) for 8 – 10 minutes

Sterilization and Sanitization

| Method | Temperature °C (°F) | Maximum Differential Pressure bar (psi) | Time4/ Cycle min |

| Steam | 125 (257) | 0.5 (7.2) | 20 |

| Hot Water | 90 (194) | 1 (14.5) | 30 |

4 The actual time required may vary as a function of the process conditions.

Filtration Guidelines

Please contact Pall for recommendations on your specific filtration process as results may vary by product, pre-filtration and filtration conditions.For additional operating guidelines, including rinsing of sheets prior to use, please refer to instructions provided by Pall.

Applications

| Grade | Application |

| T 120 T 500 T 750 T 950 |

Coarse filtration of rennet Coarse clarification of rapeseed and wheat germ oil Fine filtration of sugar syrup |

| T 1000 T 1500 T 2100 T 3500 |

Wine clarification Coarse filtration of natural extracts Coarse filtration of sugar syrup Coarse filtration of honey and edible oils |

| T 2600 T 5500 |

Sugar syrup clarification Particle removal in spirits Clarification of enzyme solutions |

Performance

Quality

- Filter sheets produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

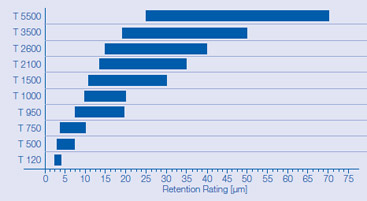

Relative Retention Rating1

1 Effective removal performance of filter sheets is dependent on process conditions.

Type

Filter Sheets

Ordering Information

Available Sheet Formats

Rectangular Sheets

- 400 mm x 400 mm (15.8 in. x 15.8 in.)

- 600 mm x 612 mm (23.6 in. x 24.1 in.)

Folded Sheets

- 1003 mm x 2016 mm (39.5 in. x 79.3 in.)

- 1205 mm x 2420 mm (47.4 in. x 95.3 in.)

Seitz T series filter sheets are also available in SUPRAdisc™ module configurations. Please contact Pall.

Reviews

We appreciate your review of this product. Please login to your account to leave a review.