ポリファインⅡ

- Proprietary filter media produced by Pall for highly consistent performance

- High contaminant-holding capacity

- Wide chemical compatibility

- Rigid polypropylene outer cage protects filter

- All polypropylene one piece construction (except 0.2 micron)

- Asymmetric polysulfone media used in 0.2 μm grade

- Fast rinse-up to 18 Megohm-cm

Performance Specifications

Filter Grades:

0.2, 0.25, 0.45, 0.8, 2, 3, 5, 10, 30, 50, 100 μmRecommended change-out differential pressure1

2.4 bard (35 psid)Maximum forward differential pressure

4.8 bard (70 psid) @ 20°C (68°F)2.8 bard (40 psid) @ 65°C (150°F)

Food and water contact use

Please contact Pall Corporation to verify that the product conforms to your national legislation and/or regional regulatory requirements for water and food contact use.Cartridge rinse-up

Rinse-up to 18 Megohm-cm with a minimum of throughput.Purity

Cartridges are free of resins, binders, and adhesives.Product Specifications

Materials of construction

| Filter Media: | |

| PFT 0.2: | Highly asymmetric polysulfone |

| All other grades: | Polypropylene |

| Hardware: | Polypropylene |

| Sealing: | Thermal bond |

| Support material: | Polypropylene |

| Gaskets/O-rings: | Silicone elastomer, nitrile, EPDM fluorocarbon elastomer, white nitrile, white silicone, expanded PTFE, FEP encapsulated silicone, high purity fluorocarbon elastomer, FEP encapsulated fluorocarbon elastomer, Kalrez2, white neoprene |

Dimensions (nominal):

| Outside Diameter: | 6.6 cm (2.6 in) |

| Lengths: | 10.2 cm (4 in), 24.8 cm (9.75 in), 25.4 cm (10 in), 49.5 cm (19.5 in), 50.8 cm (20 in), 74.3 cm (29.25 in), 76.2 cm (30 in), 99.1 cm (39 in), 102 cm (40 in) |

1 Provided that the maximum differential pressure is not exceeded based on temperature limits defined above.

2 Registered trademark of DuPont Dow.

Particle Retention (µm)

| Cartridge Designation | Liquid Service (by ASTM F-795 Test) | Gas Service | |

| 90% Efficiency | >99.9% Efficiency | Removal Efficiency By DOP Test | |

| PFT 0.2 | 0.2 | 0.5 | 99.99% |

| PFT 0.25 | 0.25 | 1.0 | 99.97% |

| PFT 0.45 | 0.45 | 1.2 | 99.93% |

| PFT 0.8 | 0.8 | 2.5 | 99.90% |

| PFT 2.0 | 2 | 5 | - |

| PFT 3.0 | 3 | 7 | - |

| PFT 5.0 | 5 | 12 | - |

| PFT 10.0 | 10 | 15 | - |

| PFT 30.0 | 30 | 40 | - |

| PFT 50.0 | 50 | 65 | - |

| PFT 100.0 | 85 | 100 | - |

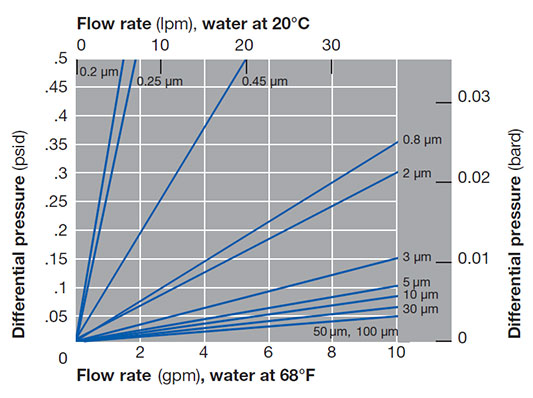

Typical Flow vs. Differential Pressure for Application Sizing

Flow rate is for a 25.4 cm (10 in) cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

Unit conversion: 1 bar = 100 kPa

Filter Cartridges

Pall Part Number = PFT [1] - [2]U[3] - [4][5][6] - [7]

Table 1

| Code | Filter grades (μm) |

| 0.2 | 0.2 |

| 0.25 | 0.25 |

| 0.45 | 0.45 |

| 0.8 | 0.8 |

| 2 | 2 |

| 3 | 3 |

| 5 | 5 |

| 10 | 10 |

| 30 | 30 |

| 50 | 50 |

| 100 | 100 |

Table 2

| Code | Cartridge lengths (cm/ in) nominal |

| 4 | 10.2/4 |

| 9.75 | 24.8/9.75 |

| 10 | 25.4/10 |

| 19.5 | 49.5/19.5 |

| 20 | 50.8/20 |

| 29.25 | 74.3/29.25 |

| 30 | 76.2/30 |

| 39 | 99.1/39 |

| 40 | 101.6/40 |

Table 3

| Code | Gasket/O-ring materials |

| S | Silicone (standard O-rings) |

| N | Nitrile (standard gaskets) |

| M | White silicone |

| W | White nitrile (gaskets) |

| V | Fluorocarbon elastomer |

| E | EPDM |

| T | FEP encapsulated silicone (O-rings) |

| T | Expanded PTFE (gaskets) |

| X | No O-ring required (M2 style only) |

| F | FEP encapsulated fluorocarbon elastomer (O-rings) |

| K | Kalrez (222 O-rings) |

| Q | High purity fluorocarbon elastomer (222 O-rings) |

| Z | White neoprene (gaskets) |

Table 4

| Code | End configurationss |

| Blank | DOE industrial |

| 1X | DOE industrial, 2.54 cm (1 in) extended core |

| M2 | SOE flat closed end, fits housings with 020 O-ring post |

| M3 | SOE flat closed end, external 222 O-rings (retrofits other manufacturers’ Code 0)3 |

| M3H | SOE large diameter closed end, external 222 O-rings |

| M4 | SOE fin end, external 222 O-rings with locking tabs |

| M5 | DOE, internal 120 O-rings (retrofits 213 O-ring style) 3 |

| M6 | SOE flat closed end, external 226 O-rings (retrofits other manufacturers’ Code 6)3 |

| M7 | SOE fin end, external 226 O-rings (retrofits other manufacturers’ Code 7)3 |

| M8 | SOE fin end, external 222 O-rings (retrofits other manufacturers’ Code 5)3 |

| M10 | DOE, internal O-rings (fits other manufacturers’ housings)3 |

| M11 | SOE flat closed end, internal 120 O-ring (retrofits other manufacturers’ X style) 3 |

| M18 | SOE flat closed end, external 222 O-ring |

| M20 | SOE, internal O-ring (same as M10), closed end with deep recess |

| M22 | SOE fin end, external 225 O-ring |

Table 5

| Code | Bubble test option |

| Blank | No bubble test |

| B | 100% bubble best |

Table 6

| Code | Pre-rinse option |

| Blank | No pre-rinse |

| 414 | 100% pre-rinse |

Table 7

| Code | Packaging |

| Blank | Standard packaging |

| -BLK | Bulk packaging |

3 For details, contact Pall Corporation.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.