Expanding the range of PCM500 fluid cleanliness monitors, the PCM500 X357 measures the cleanliness of system fluids with viscosities between 0.5 and 40

The low viscosity fluid cleanliness monitor is ideal for Fluid applications, including:

- Machine coolant fluid

- Washing fluids

- Deionised water

- Automatic transmission fluids

- Machinery and equipment test fluids

Operation

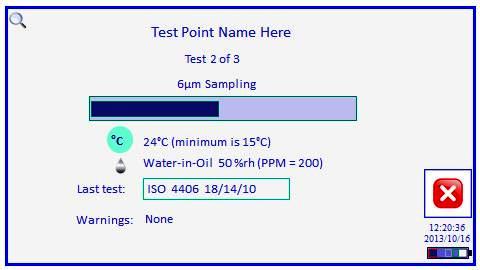

The color LCD touch screen allows simple menu-driven

The HD screen displays

All ancillary components for high and

For further protection and ease of transport, the PCM500 is supplied in a robust flight case.

| Power supply: | 90-260 VAC or integral 12 VDC Lithium Ion battery |

| Battery life: | Typically 35 samples |

| Temperature Range: |

10°C to 80°C (50°F to 176°F) (dependent on fluid type) |

| Compatibility: | Water glycols, aqueous solutions. Petroleum and synthetic oils (hydraulic lubricating, dielectric, etc.) fuels, industrial phosphate esters, DI water |

| Seals: | Nitrile |

| Operating viscosity: | 0.5 to 40 cSt (29.5 to 185.3 SUS) |

| Pressure: | 0 to 200 bar (2902 psi) max |

| Monitoring Range: | ISO 4406: <11/9/7 to 23/21/17 SAE AS 4059 Table 1 Class 1 to 12 (derived from NAS 1638) SAE AS 4059 Table 2 >4 µm 1A to 12A, >6 µm 1B to 12B >14 µm 1C to 12C |

| Accuracy: | ± 1/2 ISO 4406 Code |

| Communication Ports: | 3 x USB's (Data Acquisition, PC Setup, Printer), Ethernet and RS232C (PLC Control) |

| Enclosure: | IP 65 (NEMA 4) |

| Weight: | 11 kg (24 lb) |

| Dimensions: | 400 x 260 x 250 mm (15.8 x 10.2 x 10 inches) |

|

Multiple test data can be stored and displayed for subsequent analysis and download |

| PCM500 | M | A | X357 |

| PCM500 | M | B | X357 |

| PCM500 | M | D | X357 |

| PCM500 | U | B | X357 |

| PCM500 | U | C | X357 |

Table 1: Fitting Type

| Code | Description |

| M | 1⁄4" in. BSPP Female Swivel fitting to metric test point |

| U | 1⁄4" in. NPT fitting and end cap |

Table 2: Power Lead

| Code | Description |

| A | UK Power Lead |

| B | European Power Lead |

| C | USA Power Lead |

| D | Australian Power Lead |

Printer Kit and Accessories

PCM500-PRTFor ordering and pricing information contact your local sales office or distributor Contact Us.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.