Datasheets

ダウンロード:Gaskleen® II EL Purifier Assembly

Pall Gaskleen II EL purifier assemblies are designed to remove molecular contamination from many process gases. Sub-parts-per-billion (ppb) level purification is achieved for flow rates up to 30

- Controls and removes impurities such as moisture, oxygen, carbon dioxide, non-methane hydrocarbons, metal carbonyls, and siloxanes

- 316L stainless steel housing

Wide variety of gases purified- 100% helium leak and pressure tested

- Not orientation

sensitive - No detectable metal contribution above background in HCl gas with HCLP

materia - No detectable metal contribution above background in HBr gas with HBRP material

| Materials |

|

| Particle Removal Efficiency Rating |

|

| Connections |

|

| Operating Conditions |

|

| Packaging |

|

1Contact the Pall

2Particle rating based on laboratory testing with NaCl

3VCR is a trademark of Swagelok Co.

Technical Information

Impurity Removal as Tested in Specific Gases

| Specific Gas | Impurity Removal Efficiency |

| Inert Gases: Nitrogen, Argon, Helium, Xenon, Krypton, Neon | < 1 ppb H2O, CO2, O2, and CO as tested in argon and nitrogen using APIMS analyzer |

| Flammable Gases: Silane, Hydrogen, Methane, Ethane, Cyclopropane, Propane, Dimethyl Ether, Ethylene, Propylene, Carbonyl Sulfide | < 1 ppb H2O, CO2, O2, and CO as tested in argon, nitrogen, and hydrogen using APIMS analyzer < 1 ppb H2O as tested in carbon monoxide using trace moisture analyzer H2O and siloxanes removed to trace levels as tested in silane using APIMS |

| Carbon Monoxide | < 10 ppb Ni(CO)4 and < 1 |

| Fluoromethane, Difluoromethane, Trifluoromethane, Tetrafluoroethane, Pentafluoroethane, Heptafluoropropane, Carbon Tetrafluoride, Perfluoropropane, Perfluorocyclobutane, Hexafluoroethane | < 1 ppb H2O, CO2, and CO as tested in argon and nitrogen using APIMS analyzer < 1 < 10 ppb H2O as tested in |

| Germane | < 1 ppb H2O, CO2, and O2 as tested in argon using APIMS |

| Sulfur Hexafluoride | < 1 ppb H2O, CO2, O2, and CO as tested in argon and nitrogen |

| < 1 ppb H2O and CO2 as tested in argon using APIMS analyzer | |

| Chlorinated Gases: Boron Trichloride, Chlorine, Trichlorosilane, Dichlorosilane | < 1 ppb H2O and CO2 as tested in argon using APIMS analyzer |

| Hydrogen Chloride | < 15 ppb H2O as tested in hydrogen chloride using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Hydrogen Bromide | < 50 ppb H2O as tested in hydrogen bromide using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Photolithography Clean Dry Air | < 1 ppb H2O as tested in argon using APIMS analyzer < 300 ppt C4H8 as tested in argon using APIMS analyzer < 10 ppt SO2 as tested in nitrogen using ion < 15 ppt NH3 as tested in nitrogen using ion < 1 ppt HMDSO as tested in argon using APIMS analyzer and baseline subtraction |

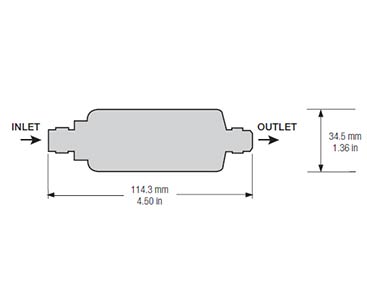

Dimensions

Part Numbers / Ordering Information

| Part Number Specification | Specific Gas | Effluent Impurity Specifications |

| GLP6INPVMM4 | Inert Gases: Nitrogen, Argon, Helium, Xenon, Krypton, Neon | < 1 ppb H2O, CO2, O2, CO |

| GLP6SIPVMM4 | Flammable Gases: Silane, Hydrogen, Methane, Ethane, Cyclopropane, Propane, Dimethyl Ether, Ethylene, Propylene, Carbonyl Sulfide Carbon Monoxide | < 1 ppb H2O, CO2, O2, CO < 1 ppb H2O, O2, CO2, Fe(CO)5 < 10 ppb Ni(CO)4 |

| GLP6FCPVMM4 | Fluoromethane, Difluoromethane, Trifluoromethane, Tetrafluoroethane, Pentafluoroethane, Heptafluoropropane, Carbon Tetrafluoride, Perfluoropropane, Perfluorocyclobutane, Hexafluoroethane | < 1 ppb H2O, CO2, O2 |

| GLP6GEH4PVMM4 | Germane | < 1 ppb H2O, CO2, O2, CO |

| GLP6SF6PVMM4 | Sulfur Hexafluoride | < 1 ppb H2O, CO2, O2, CO |

| GLP6OXPVMM4 | Oxygenated Gases: Carbon Dioxide, Oxygen, Nitrous Oxide | < 10 ppb H2O |

| GLP6CLXPVMM4 | Chlorinated Gases: Boron Trichloride, Chlorine, Trichlorosilane, Dichlorosilane | < 100 ppb H2O |

| GLP6HCLPVMM4 | Hydrogen Chloride | < 15 ppb H2O |

| GLP6HBRPVMM4 | Hydrogen Bromide | < 50 ppb H2O |

| GLP6CDAPVMM4 | Photolithography clean dry air | < 1 ppb H2O, < 300 ppt organics (as C4), < 10 ppt acid gases (as SO2), < 15 ppt basic gases (as NH3), < 1 ppt refractory compounds (as HMDSO) |

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.