Datasheets

ダウンロード:The Ultipleat P-Nylon filter is recommended specifically for bulk filtration of photoresists, solvents, TMAH-based developers and other chemicals, that are compatible with nylon 6,6 and High Density Polyethylene (HDPE). The filter design incorporates the latest advance in Pall filtration technology: the crescent shaped Ultipleat® filter configuration.

- Naturally hydrophilic

- Quick venting

- Wide range of configurations

- High flow rates

- Integrity testable

- Low extractables

- Manufactured in a cleanroom environment

- 100% integrity tested

Materials

- Medium: Hydrophilic nylon 6,6

- Core, cage, and end caps: High Density Polyethylene (HDPE)

- Support and drainage: High Density Polyethylene (HDPE)

- O-ring options: Fluoroelastomer and FEP encapsulated elastomer

Removal Ratings

- 0.1 μm, 40 nm, 20 nm

Filter Areas

- 0.1 μm UNI: 0.93 m2 / 10 ft2 per 10 in.

- 40 nm UND: 1.2 m2 / 13 ft2 per 10 in.

- 20 nm UNM: 1.4 m2 / 15 ft2 per 10 in.

Configurations

- Nominal length:

- 254 mm / 10 in.

- 508 mm / 20 in.

- 762 mm / 30 in.

- 1016 mm / 40 in.

- Diameter: 70 mm / 2.75 in.

- O-ring size / end caps:

- Code 3: 222 double O-ring / flat end

- Code 8: 222 double O-ring / finned end

- Code 7: 226 double O-ring bayonet lock / finned end

- MR Code 3: 222 double O-ring / flat end designed to retrofit Code 0 elements

Operating Conditions

- Maximum operating temperature: 50 °C / 120 °F

- Maximum forward / reverse differential pressure: 275 kPa @ 20 °C / 40 psid @ 68 °F

Recommended Applications

- Anti-reflective coatings

- Up to 3% TMAH-based developers

- i-line, 248 nm, and 193 nm photoresists

- Solvents

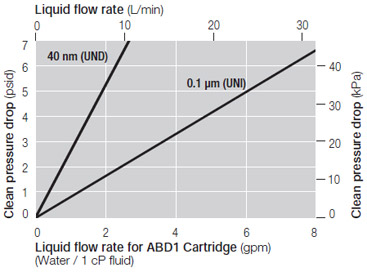

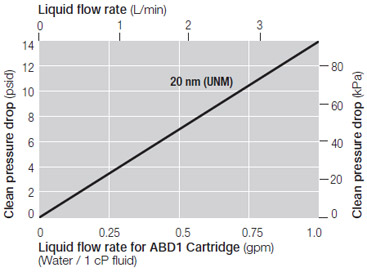

Pressure Drop vs. Liquid Flow Rate

カートリッジ/エレメント

| Part Number1 | Removal Rating | Nominal Length (mm / in.) | Configuration Code | O-Ring Material2 |

| ABD1UNI3EH1 | 0.1 μm | 254 / 10 | 3 | FEP encapsulated elastomer |

| ABD1UNI8EH1 | 0.1 μm | 254 / 10 | 8 | FEP encapsulated elastomer |

| MRD1UNI3EH1 | 0.1 μm | 254 / 10 | 3 | FEP encapsulated elastomer |

| ABD1UND3EH1 | 40 nm | 254 / 10 | 3 | FEP encapsulated elastomer |

| ABD1UND8EH1 | 40 nm | 254 / 10 | 8 | FEP encapsulated elastomer |

| ABD1UNM3EH1 | 20 nm | 254 / 10 | 3 | FEP encapsulated elastomer |

| ABD1UNM8EH1 | 20 nm | 254 / 10 | 8 | FEP encapsulated elastomer |

1The above filter configurations are also available in 508 mm / 20 in., 762 mm / 30 in., and 1016 mm / 40 in. lengths. These can be ordered by changing the fourth digit in the part number to a 2, 3, or 4 respectively.

2 Other O-ring materials are available.

Unit conversion: 1 bar = 100 kilopascals

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.