カタログ・技術資料

Datasheets

ダウンロード:概要

The P-Nylon EX filter is specifically designed to target defects in the next generation lithography process. The Nylon Effect, which has proven to significantly reduce microbridge and cone defect in 193 nm resist and BARC chemicals, can now be applied to all lithography applications. The increased adsorption functionality and improved flow performance enhance the removal of hardly soluble polymer components. (almost 4 times increased gel capture capacity compared to the conventional Ultipleat® P-Nylon filter) This enhanced adsorption will contribute to further defect reduction.

Features and Benefits

- Naturally hydrophilic (no surface modifications)

- Low extractables

- Enhanced adsorption capabilities

- Reduces defects by optimizeding filter “Contact Time”

- Wide range of available configurations Disposable filter capsule: PHD, DDF Filter cartridge: ABD

仕様

Materials

| Components | Materials |

| Medium | Hydrophilic Asymmetric Nylon6,6 |

| Support and Drainage | High Density Polyethylene (HDPE) |

| Core, Cage, and End Caps | High Density Polyethylene (HDPE) |

| Housing 1 | High Density Polyethylene (HDPE) |

| O-ring options 2 | PHD12, PHD13 : Perfluoroelastomer ABD1 : FEP encapsulated fluoroelastomer |

Specifications

| Filter Areas | PHD12 : 1,100 cm2 PHD13 : 2,200 cm2 DDF1 : 1,600 cm2, DDF2 : 3,300 cm2, ABD1 : 9,400 cm2 |

| Maximum Operating Temperature | PHD12, PHD13, DDF1, DDF2 : 30 °C / 86 °F ABD1 : 50 °C / 120 °F |

| Maximum forward differential pressure | PHD12, PHD13, DDF1, DDF2 : 0.29 MPa @ 30 °C / 42 psi @ 86 °F ABD1 : 0.27 MPa @ 20 °C / 40 psi @ 68 °F |

| Maximum Operating Pressure 3 | 0.29 MPa @ 30 °C / 42 psi @ 86 °F |

1 PHD12, PHD13, DDF1 and DDF2 capsules

2 PHD12, PHD13, capsules and ABD1 cartridges

3 PHD12, PHD13, DDF1 and DDF2 capsules

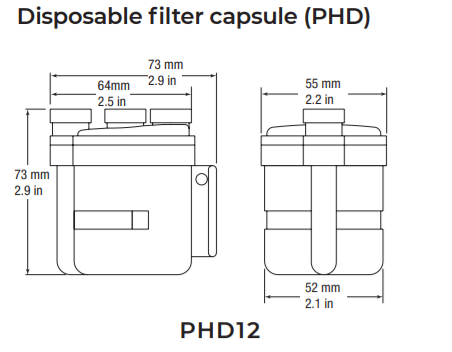

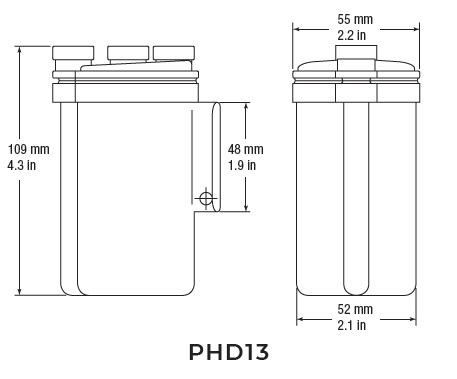

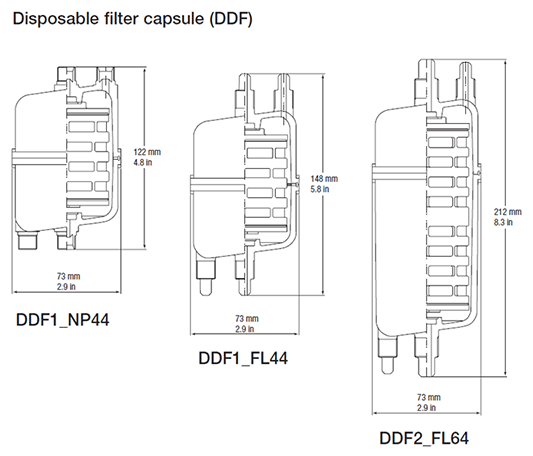

Dimensions

性能

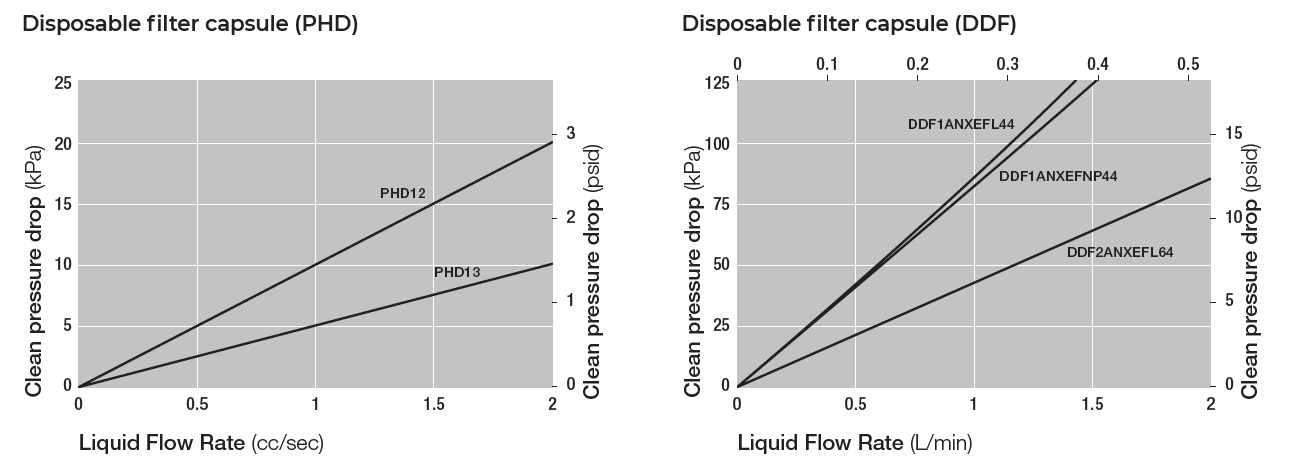

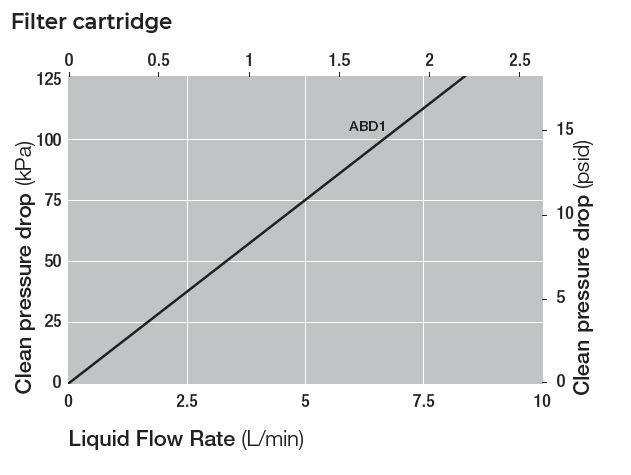

Typical Flow Characteristics - 1cP fluid, 20℃

製品カテゴリー

型式

Part Number/Ordering Information5

| Part Number | Nominal Length (mm / in) |

Configuration | O-Ring Material or Capsule Connections |

| PHD12ANXEH11B | 73 / 2.9 | Disposable Capsule | Perfluoroelastomer |

| PHD13ANXEH11B | 109 / 4.3 | Disposable Capsule | Perfluoroelastomer |

| DDF1ANXENP44 | 122 / 4.8 | Disposable Capsule | 1/4” Super Pillar 6 / 1/4” Super Pillar |

| DDF1ANXEFL44 | 148 / 5.8 | Disposable Capsule | 1/4” Flare style / 1/4” Flare style |

| DDF2ANXEFL64 | 212 / 8.3 | Disposable Capsule | 3/8” Flare style / 1/4” Flare style |

| ABD1ANX3EH1 | 254 / 10 | Code 3 cartridge 222 double O-ring / flat end |

FEP encapsulated fluoroelastomer |

| ABD1ANX8EH1 | 254 / 10 | Code 8 cartridge 222 double O-ring / finned end |

FEP encapsulated fluoroelastomer |

| ABD2ANX3EH1 | 508 / 20 | Code 3 cartridge 222 double O-ring / flat end |

FEP encapsulated fluoroelastomer |

| ABD2ANX8EH1 | 508 / 20 | Code 8 cartridge 222 double O-ring / finned end |

FEP encapsulated fluoroelastomer |

4 Pillar is a trademark of Nippon Pillar Packing Co., Ltd

5 For XP treatment option, add -XP to the end of a part number for PHD and DDF

レビュー

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.