XプレスクリーンG2、XプレスクリーンG2・KC (5 nm)

Datasheets

ダウンロード:Description

The XpressKleen G2 XP 5 nm filter represents a significant advance in the development of microporous PTFE membranes to meet the severe contamination control challenges that exist below the 14 nm manufacturing node. Pall Corporation’s material science team of scientists and engineers has created a new filter morphology unlike current designs using newly developed proprietary PTFE membrane manufacturing technology.

The revolutionary design provides unparalleled control of critical size particles greater than 5 nm combined with a new standard of device cleanliness and purity that guarantees less than 500 ppt of total metal ion extractables per single length filter1. Proprietary advanced cleaning methods produce a filter with ultra-low levels of organics, NVR, and transient surface borne particles.

Every aspect of the XpressKleen XP 5 nm filter, from the PTFE resin to the final package, is designed, controlled, and manufactured to deliver unparalleled and elevated performance that is consistent, repeatable, and a new standard in sub 7 nm particle retention.

The unique combination of low differential pressure and measured retention at 5 nm makes the filter suitable for use from the point of supply (POS) to the point of process (POP), in bulk delivery, recirculating batch filtration, and in single wafer applications.The XpressKleen 5 nm filter is an integral part of a contamination control system that enables particle and purity defect levels needed for 10 nm and finer manufacturing.

The nondewetting XpressKleen G2 filter is qualified for use in aggressive high temperature cleaning chemistries like SPM, H3PO4; concentrated chemicals like NH4OH, HCl, H2SO4, H2O2; IPA and other solvents; high ppm DIO3, and aqueous chemistries such as SC1 and SC2.

- Low extractables < 500 ppt total of 19 elements

< 0.1 ppb (Ni), < 0.2 ppb (Cu) - > 20nm particle rinse up control in UPW

- TOC control

- 100% prewetted shipment with ultrapure water package

- High flow rates

- G2 KC assembly available with downstream venting

- Disposable filter unit with filter cartridge integrally sealed in housing

- Sealed assembly for safer handling and faster changeout

- 100% integrity tested

1 Total metal concentrations of 19 elements for KC Assemblies: Al, Ba, B, K, Na, Fe, Li, Mg, Mn, Pb, Sn, Ti, Zn, Ni, Cu, Cr, Co, Ca, Ag. Consult factory for details.

Materials of Construction2

| Parts | Material |

| Filter Medium | Surface-modified PTFE |

| Media Support | PFA |

| Core, cage and end caps | PFA |

| Housing | PFA |

| O-ring options3 | FEP-encapsulated fluoroelastomer,FFKM |

2 All perfluoro-polymer materials made without PFOA.

3 Consult factory for other options.

Removal Ratings and Operating Conditions

Kleen-Change® (KC)

| Removal Ratings | 5 nm |

| Media Code | XP5 |

| Filter Area | 2.8 m2 |

| Flow | Inline, L-flow, T-flow |

| Metallic extractables4 | < 500 ppt4 |

| Maximum Operating Temperature | 185 °C / 365 °F |

| Maximum Operating Pressure | 0.49 MPaG ( 71 psig) @ 25°C (77°F) 0.39 MPaG (56.6 psig) @ 60°C (140°F) 0.34 MPaG (49.3 psig) @ 90°C (194°F) 0.20 MPaG (29.0 psig) @ 120°C (248°F) 0.15 MPaG (21.8 psig) @ 150°C (302°F) 0.12 MPaG (17.4 psig) @ 185°C (365°F) |

Cartridge

| Removal Ratings | 5 nm | |

| Media Code | XP5 | |

| Filter Area | ABFG1 | 2.8 m2 |

| Metallic extractables4 | < 1 ppb4 | |

| Maximum Operating Temperature | 185 °C / 365 °F | |

| Maximum Differential Pressure | 0.59 MPaG (85.6 psig) @ 50°C (120°F) | |

4 19 elements, consult factory for test conditions

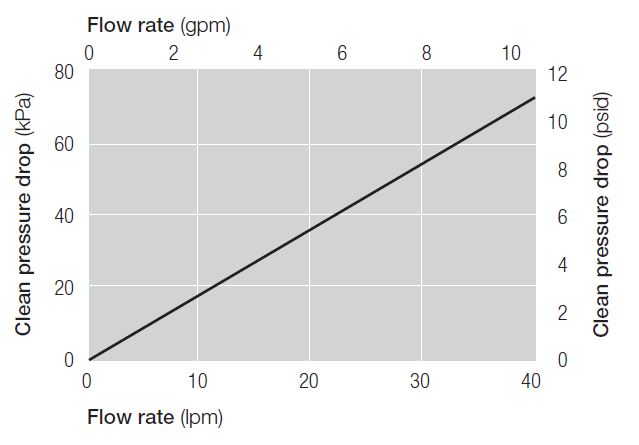

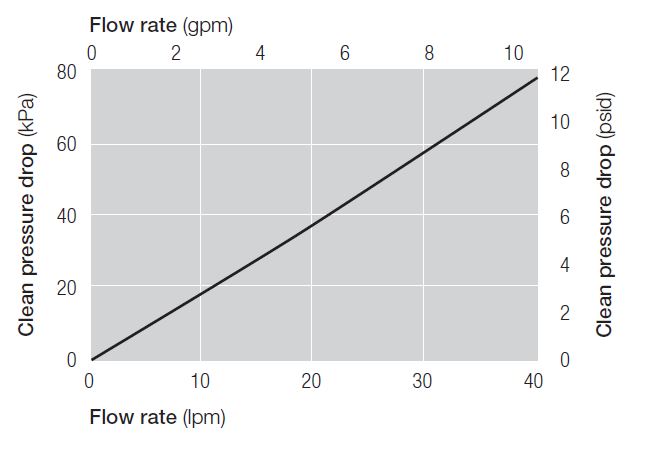

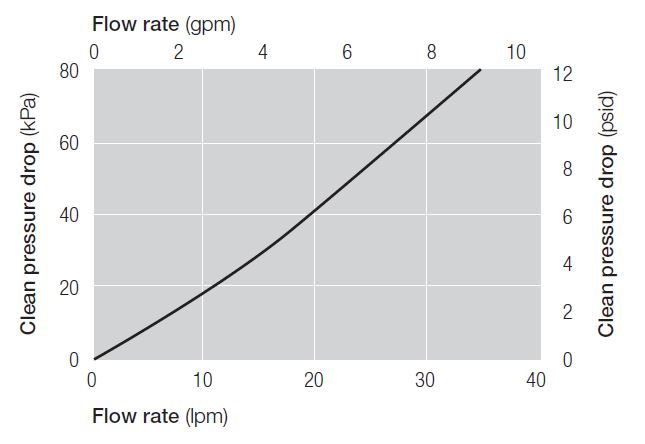

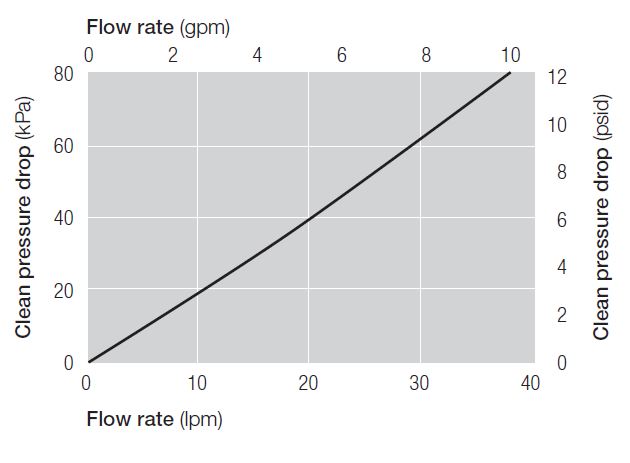

Typical Flow Characteristics - 1cP fluid, 20℃

G2 cartridge

1" KC (In-line, T-flow)

3/4" KC (L-flow, T-flow)

3/4" KC (In-line)

XpressKleen G2 KC Assemblies

LDF [1][2] 1XP [3][4] E [5]

Table 1 |

|||||

| Code | Downstream vent | ||||

| G | N/A | ||||

| V | Available | ||||

Table 2 |

|||||

| Code | Flow | ||||

| T | T-flow | ||||

| N | In-line | ||||

| L | L-flow | ||||

Table 3 |

|||||

| Code | Removal rating | ||||

| 5 | 5 nm | ||||

Table 4 |

|||||

| Code | Inlet/Outlet | Vent/Drain | Type | ||

| Head end | Bowl end | ||||

| 12 | 3⁄4 in male | 1⁄2 in male | 1⁄2 in male | T-flow/L-flow | |

| 12 | 3⁄4 in male | 1⁄2 in male | 1⁄2 in female | DV type | |

| 12 | 3⁄4 in male | 3⁄8 in male | 3⁄8 in male | In-line | |

| 124 | 3⁄4 in male | 1⁄4 in male | 1⁄4 in male | In-line | |

| 128 | 3⁄4 in male | 1⁄2 in male | 1⁄2 in male | DV type | |

| 13 | 3⁄4 in male | 1⁄2 in female | 1⁄2 in female | T-flow | |

| 16 | 1 in male | 1⁄2 in male | 1⁄2 in male | T-flow | |

| 16 | 1 in male | 1⁄2 in male | 1⁄2 in female | DV type | |

| 16 | 1 in male | 3⁄8 in male | 3⁄8 in male | In-line | |

| 164 | 1 in male | 1⁄4 in male | 1⁄4 in male | In-line | |

| 168 | 1 in male | 1⁄2 in male | 1⁄2 in male | DV type | |

| 17 | 1 in female | 1⁄2 in female | 1⁄2 in female | In-line | |

DV : Downstream VentingTable 56 |

|||||

| Code | Connections | ||||

| 1 | 20 series Flowell7 | ||||

| 2 | Super Pillar type8 | ||||

| 51 | Flare style | ||||

| 6 | FinalLock9 | ||||

| 71 | Super Pillar 300 P series | ||||

| 72 | Super Pillar 300 P series L type | ||||

| 8 | 60 series Flowell | ||||

| 9 | 11CR series Flowell | ||||

6 Disposable capsules are not available with every option. (Refer to codes for options.) Contact your local Pall representative for option availability.

7 Flowell is a trademark of Flowell Corporation.

8 Super Pillar is a trademark of Nippon Pillar Packing Co., Ltd.

9 FinalLock is a trademark of Kurabo Industries Ltd.

XpressKleen G2 Filter10

ABFG [1] XP [2] 3E [3]

Table 1 |

||

| Code | Length (Nominal) | |

| Inch | mm | |

| 1 | 10 | 225 |

| 2 | 20 | 468 |

Table 2 |

||

| Code | Removal rating | |

| 5 | 5 nm | |

Table 3 |

||

| Code | O-ring material | |

| H1 | FEP-encapsulated fluoroelastomer | |

| H35 | Perfrez11 | |

| H38 | FFKM | |

10 Cartridges are shipped prewet as standard.

11 Perfrez is a trademark of Applied Seals North America, Inc.

Earn 10% off* your next order online by leaving a review of this product. Please login to your account to leave a review. We appreciate and value your feedback.

*Subject to Terms and Conditions.