Description

Indicate when the aircraft filter element is becoming blocked and needs to be changed. Use as part of your diagnostics program.

- Aids with maintenance planning

- Advance warning of filter blockage

- Extensive range of indicators to choose from

- Compact and lightweight

Pall manufactures a series of mechanical and electrical indicators, with a range of connectors, qualified for aerospace use.

Features

- Visual 'Pop' Up button or Electrical Indication or both

- Wide range of pressure settings

- Thermal lock out device (optional)

Benefits

- Advance warning of filter element blockage

- Thermal lock out device prevents false indication at cold start conditions

- Aerospace OEM approved

How does an aerospace differential pressure indicator/switch work?

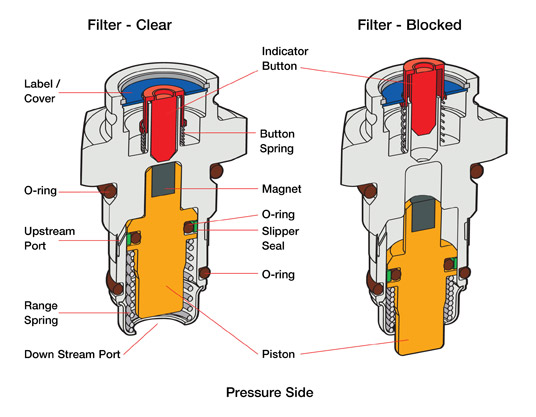

Deltadyne® differential pressure devices operate by sensing the differential pressure between ports upstream and downstream of the filter element. The differential pressure acts on a piston/magnet assembly that is contained in the indicator device.

Principle of Operation:

- The differential pressure across the internal piston/magnet assembly reaches a preset value. This is determined by the range spring.

- The piston (including magnet) moves downward. This reduces the attractive force between the magnet and the button/switch and therefore the button/switch actuates. In a DPI, the red indicator warning button pops up. In a DPS, the switch moves to the open position.

This indicates the filter element requires changing. - When the differential pressure reduces (i.e. a new element is installed), the piston returns to its original position.

- The button/switch is re-set and is ready for use again.

Thermal Lock-Out

In some systems, operation at low temperatures can cause a false indication of a blocked element. To prevent this, an optional thermal lock-out device can be provided. At the stated temperature (e.g. below 100°F, 37.8°C), a bimetallic strip, mounted adjacent to the indicator button, curves inwardly sufficiently to prevent the button from rising. The same feature can also be programmed electronically.

Reed Switch or Microswitch?

A microswitch is typically used for high current applications and a reed switch is typically used for low current applications. The reed switch is hermetically sealed from the atmosphere and this protects the electrical contacts from oxidation.

Applications

Pall’s differential pressure indicators and switches are qualified for a wide variety of systems:

- Engine Lube

- Engine Fuel

- Hydraulics

- Helicopter Gearbox Transmissions

- Liquid cooling systems

Type

Use

Ordering Information

Our Delta-P indicators (DPI) and switches (DPS) are designed and tailored to meet the customer specification requirements.

If you have an aerospace application that needs a DPI or DPS, please talk to one of our experts Contact Aerospace.

For commercial aircraft products, please contact our authorised distributor, Satair.

Reviews

We appreciate your review of this product. Please login to your account to leave a review.