Documents

Datasheets

Download:Description

Introduction

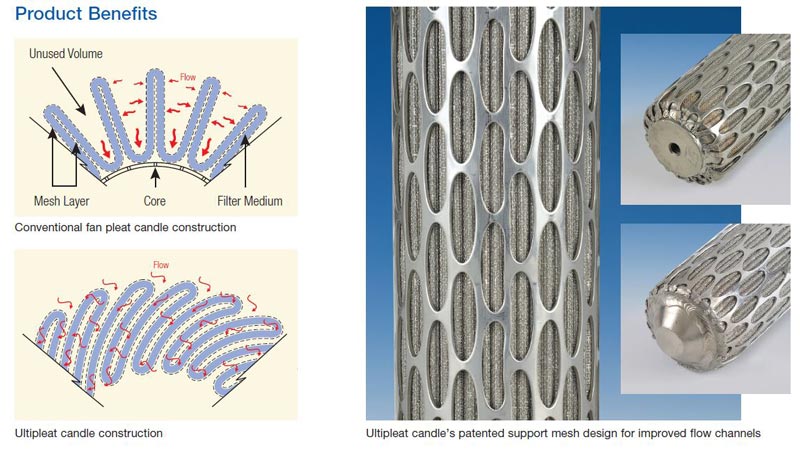

Pall’s new Ultipleat Plus metal fiber filters employ Pall Corporation’s unique “Laid Over Pleat” technology to offer extended service life to your process applications. This upgraded version of the Ultipleat candle element also utilizes a patented support mesh design for improved flow channels allowing for a much lower resistance to flow. The customizable filter elements can either be retrofitted to an existing housing or can be specially designed for the needs of your specific application. The Ultipleat Plus is great for applications with high temperature and high dirt-holding capacity requirements and for those that are looking to extend the on-stream life of their filters.

- Ideal for polymer melt filtration applications

- Available in a range of media grades and materials to best suit the needs of your specific application

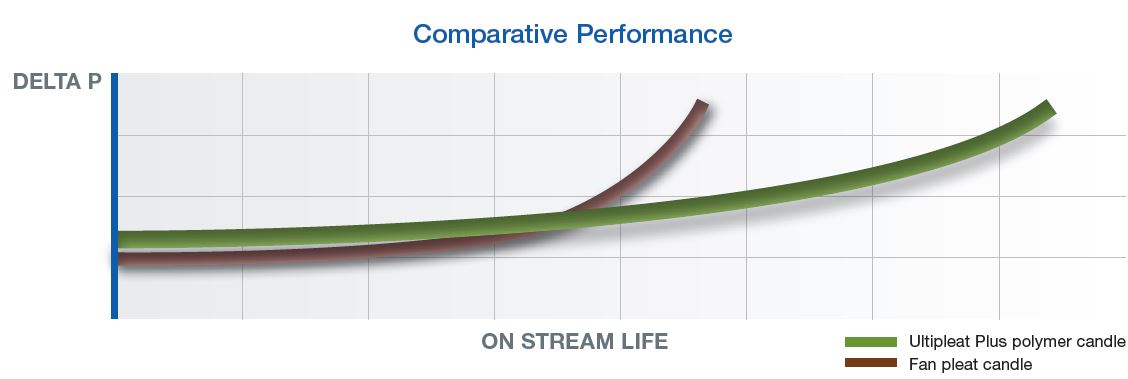

Greater surface area with Pall’s proprietary laid-over pleat geometry allowing for even flow distribution and more dirt-holding capacity- 25-50% longer on-stream life than traditional fan pleat candles

- Shorter residence times and narrower residence time distribution

- Retention ratings from 7

micron and up - Manufactured under ISO 9001 quality system

Specifications

Performance Specifications

Standard filter grades

Standard filter grades7 μm and up

Maximum differential pressure

128 bard (1850

Maximum operating temperature

330°C (626°F)

Product Specifications

Standard materials of construction304, 304L, 316, 316L

Standard Dimensions (nominal)

Outside Diameters: 1.375” – 2.75”

Lengths: 26 inch (66 cm) Sections

Applications

Typical Applications

Ultipleat Plus candles are recommended for polymer melt applications where fine filtration is required and where an increase in on-stream life is desired. They are also beneficial for applications where a lower residence time and/or a smaller residence time distribution is needed. Ultipleat Plus candles can be used with a variety of polymers, including, but not limited to:

- Polyester (PET)

- Carbon Fiber Precursor (PAN)

- Nylon (PA 6, PA6,6, etc.)

- Recycled Polymers (rPET, etc.)

- Polyurethane

- And many more!

Performance

| Features | Advantages | Benefits |

| Laid Over Pleat |

|

|

| Layered Construction |

|

|

Type

Additional Information

Materials of Construction

316/316L SST; 310 SST; Inconel4 600; Hastelloy5 X; Hastelloy5 C-2000; Haynes5 HR-1605

4 Inconel is a registered trademark of Special Metals Corporation.

5 Hastelloy, Haynes, and HR-160 are registered trademarks of Haynes International, Inc.

Ordering Information

Reviews

We appreciate your review of this product. Please login to your account to leave a review.