Documents

Cleaning Document

Download:Datasheets

Download:Description

Since 1946, Pall has pushed the limits of science and technology to solve the most complex filtration, separation and purification challenges. The Oenoflow PRO XL-A System was built to help wineries achieve two important goals:

• Reduce energy usage to support goals for net zero carbon emissions

• Reduce water usage given considerable water shortages experienced in many regions

Data shows significant reductions in both energy and water usage of up to 60% with Oenoflow PRO XL-A when compared to traditional Oenoflow systems.1

The Oenoflow PRO XL-A systems are specifically designed to meet the needs and requirements of large wineries and bottlers. Clarification is achieved in a single process step without the need for filter aids, centrifugation or significant impact on the organoleptic characteristics of the wine. By increasing yields, reducing waste volumes and maintaining more consistent filtrate quality, the fully automated systems provide a cost saving sustainable alternative to traditional wine clarification methods.

The system utilizes Pall’s proven hollow fiber membranes with unique mechanical strength and excellent chemical resistance which allow high productivity and repeated exposure to aggressive cleaning regimes. The large surface area modules enable manufacture of compact systems with low water and chemical consumption in line with winery conservation programs.

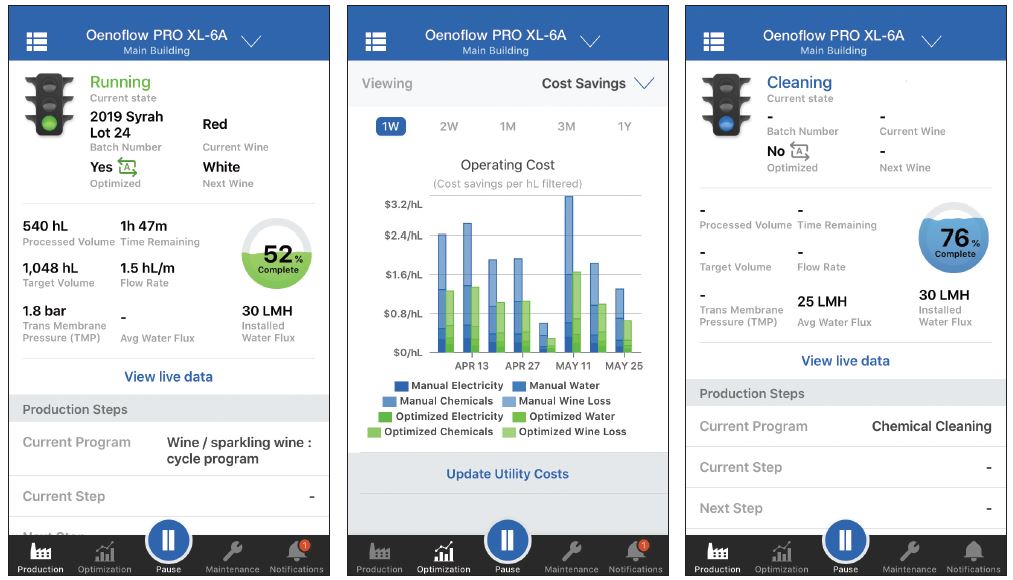

The Oenoflow PRO XL-A system utilizes Pall’s proprietary Optimizer algorithm that analyzes production data and automatically adjusts operating parameters in real time to maximize system efficiency. This feature can deliver significant savings in operating expense (OPEX). The system is connected to Pall servers which allows the user easy access to their data through Pall’s Oenoflow PRO app or browser portal.

With customizable operating cycles, process trend recording and a wide range of options, the Oenoflow PRO XL-A system offers an advanced solution with the flexibility required in most modern wine cellars, custom crush and bottling operations.

1 Reductions in energy and water usage are based on Pall’s own trial results and actual reductions may vary.

Specifications

Standard Filtration Skid Specifications

| Model | No. of modules | Filter Area (m2) | Average flow rate2 | Length | Width | Height | Weight (empty) |

| Oenoflow XL-5A | 5 | 107.5 | 50 - 75 hl/h (1320 – 1980 gal/h) |

3.35m (10.99 ft) |

1.60 m (5.25 ft) |

2.45 m (8.04 ft) |

1880 kg (4145 lbs) |

| Oenoflow XL-6A | 6 | 129 | 60 - 90 hl/h (1585 – 2380 gal/h) |

3.30 m (10.82 ft) |

1.60 m (5.25 ft) |

2.45 m (8.04 ft) |

1940 kg (4275 lbs) |

| Oenoflow XL-8A | 8 | 172 | 80 - 120 hl/h (2115 – 3170 gal/h) |

3.65 m (11.97 ft) |

1.85 m (6.07 ft) |

2.45 m (8.04 ft) |

2480 kg (5465 lbs) |

| Oenoflow XL-10A | 10 | 215 | 100 - 150 hl/h (2640 – 3960 gal/h) |

3.90 m (12.79 ft) |

1.85 m (6.07 ft) |

2.45 m (8.04 ft) |

2570 kg (5665 lbs) |

| Oenoflow XL-12A | 12 | 258 | 120 - 180 hl/h (3170 – 4755 gal/h) |

4.15 m (13.61 ft) |

1.85 m (6.07 ft) |

2.45 m (8.04 ft) |

2670 kg (5885 lbs) |

| Oenoflow XL-14A | 14 | 301 | 140 - 210 hl/h (3700 – 5550 gal/h) |

4.40 m (14.43 ft) |

1.85 m (6.07 ft) |

2.45 m (8.04 ft) |

2750 kg (6060 lbs) |

| Oenoflow XL-16A | 16 | 344 | 160 - 240 hl/h (4225 – 6340 gal/h) |

5.10 m (16.73 ft) |

1.85 m (6.07 ft) |

2.67 m (8.76 ft) |

3150 kg (6945 lbs) |

| Oenoflow XL-18A | 18 | 387 | 180 - 270 hl/h (4755 – 7130 gal/h) |

5.35 m (17.55 ft) |

1.85 m (6.07 ft) |

2.67 m (8.76 ft) |

3250 kg (7165 lbs) |

2 The flow rates for the various Oenoflow XL models are averages for the complete filtration cycle, and dependent on the wine characteristics and pre-treatment.

Type

Additional Information

Environmental Impact

The Oenoflow PRO XL-A systems incorporate unique features which enable wineries to perform clarification with the lowest environmental impact while maintaining wine quality. These include:

• Pall’s unique Optimizer algorithm which has been shown to reduce energy use and water consumption when compared to traditional Oenoflow systems

• PVDF membranes with high mechanical strength for longer service life

• High area, high flow modules for more compact and more economical systems

• Back pulse capability for increased system productivity

• Transparent module housings to confirm filtrate quality and enhance troubleshooting capabilities

• Fully automated, customizable working cycles for unattended operation and reduced labor and downtime

• On board concentration tank with wine transfer pump for operation independent of winery conditions

• Proprietary Low Concentration Volume (LCV) option for high wine yield

• Automated chemical dosing for safe and easy cleaning

• Frequency controlled pumps for automatic flow or pressure controlled operation

• Process trend recording for monitoring and optimizing filtration performance and troubleshooting

Oenoflow PRO XL-A Standard Components

The Oenoflow PRO XL-A systems are fully automated, modular systems available with 5 up to 18 crossflow filtration modules. All metal wetted parts are 304 Stainless steel. The piping manifold, membranes, pumps and instruments are mounted on a mobile frame which includes the following:

• Transfer pump with stainless steel cover for incoming wine supply

• Stainless steel pre-filter screen for large particles

• On board concentration/cleaning tank with spray ball

• Feed pump with stainless steel cover

• Circulation pump

• Filtrate reservoir

• Filtrate/back flush pump with stainless steel cover

• Magnetic flow meter with batch control

• CIP system with 1 micron, 40 inch water filter and temperature control

• Automatic chemical dosing with 3 supply inlets

• Color touch screen with process flow diagram and trend recording

• Modem for quick and easy tele-service

• Conductivity meter

Oenoflow PRO XL-A Standard Options

The following options are available for additional supply:

• Low Concentration Volume (LCV)

• Tank Distribution System (TDS) for 3 inlets and 3 outlets

• Nitrogen purge and blanketing

• Automatic dual pre-filter screens

• Extra large water filtration assembly (3 cartridges)

• Analog turbidity meter

• Sanitary sampling valve

• 4th chemical supply inlet

• External bleed

• Illuminated sight glass

• Dummy modules for future expansion capacity

• High Pressure (HP) option for treatment of sparkling wine under isobaric conditions

• Spare parts package

Oenoflow XL Membranes

The Oenoflow PRO XL-A modules incorporate Pall’s proven symmetric hollow fiber membranes. The large diameter, high flow modules with 21.5 square meters of filter area, have at least twice the filter area of typical competitive hollow fiber modules. The module components include:

Membrane: PVDF

Potting: Epoxy resin

Sleeve: Polypropylene

Housing: Transparent polysulfone

Seals: Ethylene Propylene copolymer

Compliance

Oenoflow PRO XL-A systems are CE to demonstrate compliance with relevant regulations including the European Pressure Directives.

Operating Conditions

Wine FiltrationInlet pressure: 0.5 bar to 3.5 bar (7 psi to 50 psi)

Temperature: -4 °C to 25 °C (24 °F to 77 °F)

Maximum temperature for cleaning: 65 °C (150 °F)

Reviews

We appreciate your review of this product. Please login to your account to leave a review.