Documents

Datasheets

Download:Description

Ultipleat PK1 filter cartridges are designed for high flow rate, aqueous applications required on 8G to 11G FPD processes. These filters can handle flow rates in excess of 600 L/min, thereby reducing the system footprint and change-out costs. Ultipleat PK1 filters are available in four filter media types; highly asymmetric hydrophilic polysulfone, hydrophilic PTFE, hydrophobic PTFE and ECTFE with removal ratings from 0.05 μm to 10 μm.

Features & Benefits

- Ideally suited for most FPD wet processing applications, such as substrate cleaning, etching, stripping and DI water flushing

- Broad choice of membranes and removal ratings for ease of filter selection

- Unique, Ultipleat filter construction allows for high flow rates

- Compact design makes for efficient filter change-outs, thus reducing equipment down-time

Materials of Construction

| Components | Materials | |||

| Filter media | Hydrophilic Polysulfone | Hydrophilic PTFE | Hydrophobic PTFE | ECTFE |

| Support | Polypropylene | |||

| Core | Polypropylene | |||

| End caps | Polypropylene | |||

| Sealing options | EPDM, FEP encapsulated Fluoroelastomer | |||

Specifications

| Filter media | Hydrophilic Polysulfone | Hydrophilic PTFE | Hydrophobic PTFE | ECTFE |

| Removal Ratings (μm) | 0.05, 0.1, 1.0 | 1.0, 3.0 | 3.0, 10 | 10 |

| Maximum Operating Temperature | 50 ˚C / 122 ˚F | 80 ˚C / 176 ˚F | ||

| Maximum Differential Pressure | 0.41 MPa @ 20 ˚C / 60 psid @ 68 ˚F | |||

| Housing Reference | Ultipleat PK1 housing : Part Number : 1PKVV1GF40H (PVC components) (Please contact your Pall representative for information on our stainless steel housings) |

|||

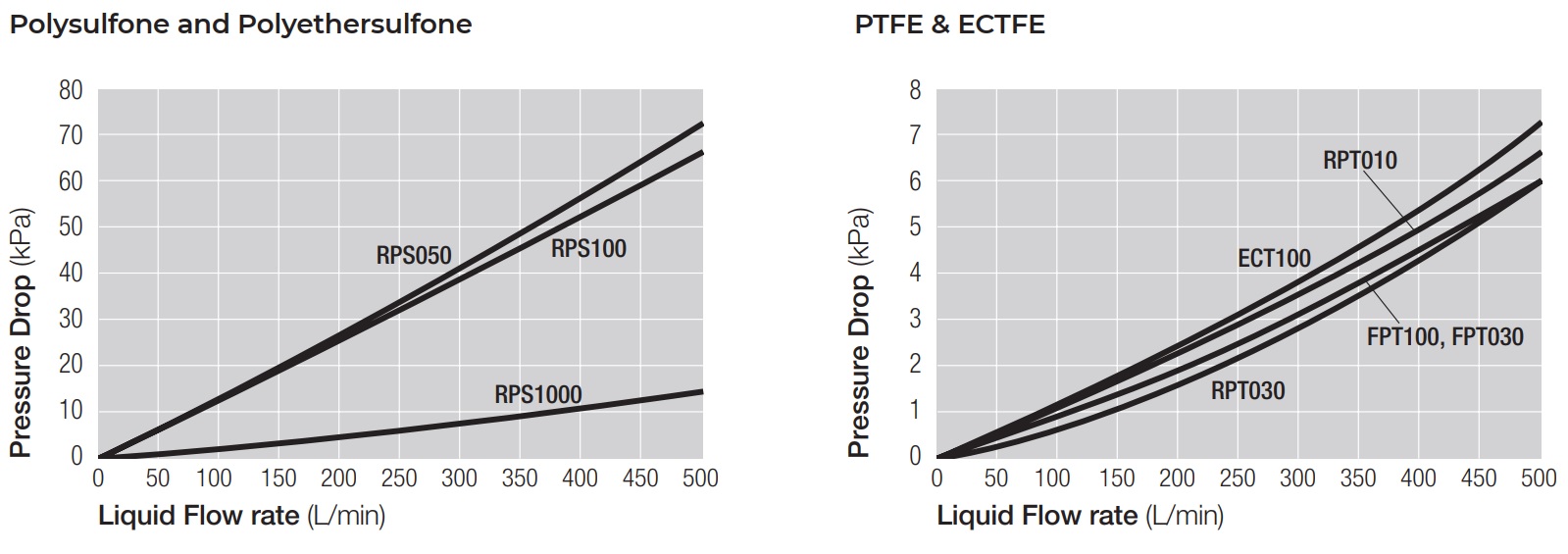

Typical Flow Characteristics - 1 cP fluid, 20 °C

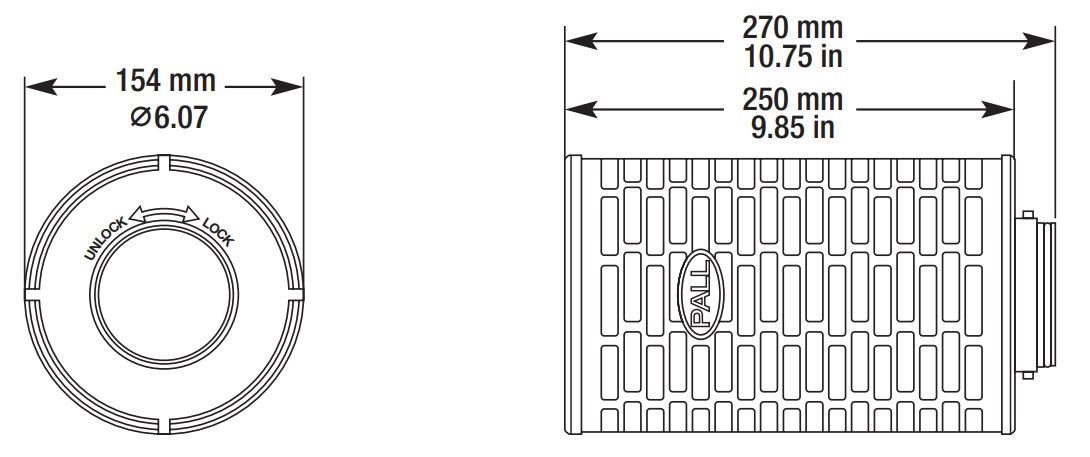

Dimensions

Type

Filter Cartridges

Ordering Information

PK1 [1] [2] [3]

Table 1

| Code | Filter Media | Removal ratings (μm) |

| RPS050 | Hydrophilic Polysulfone | 0.05 |

| RPS100 | 0.1 | |

| RPS1000 | 1.0 | |

| RPT010 | Hydrophilic PTFE | 1.0 |

| RPT030 | 3.0 | |

| FPT030 | Hydrophobic PTFE | 3.0 |

| FPT100 | 10 | |

| ECT100 | ECTFE | 10 |

Table 2

| Code | O-ring materials |

| J | EPDM |

| H1 | FEP encapsulated fluoroelastomer |

Table 3

| Code | Package Option |

| None | 6 pcs / Pack |

Representative example part numbers

| (Highly Asymmetric Hydrophilic Polysulfone Media) PK1RPS050H1 PK1RPS100H1 PK1RPS1000H1 |

(PTFE Media) PK1RPT010H1 PK1RPT030H1 PK1FPT030H1 PK1FPT100H1 |

(ECTFE Media) PK1ECT100H1 |

Reviews

We appreciate your review of this product. Please login to your account to leave a review.