Documents

Datasheets

Download:Description

Pall's Gaskleen® PG purifier assemblies have been designed to handle process flow rates up to 1,000 slpm.

- An optional bypass manifold is available complete with isolation valves and backplate for easy mounting.

- Pall's purification materials are available in every standard configuration.

- All purifier assemblies contain an integral 316L stainless steel particle filter.

- 100% helium leak and pressure tested.

- No detectable metal contribution above background in HCl gas with HCLP material

- No detectable metal contribution above background in HBr gas with HBRP material

Specifications

Assembly Flow Rates

- PG550: 75

slpm - PG2400: 500

slpm - PG11000: 1,000

slpm

Particle Filter Options

- PG550/PG2400: 0.4 μm or 0.003 μm

- PG11000: 0.4 μm

Connections

- 1⁄4 in. or 1⁄2 in. gasket seal (VCR1 or compatible) male/male

- Inlet/outlet isolation valves (for PG11000)

Assembly Material

- Electropolished 316L SS

- <0.25 μm/<10 μin Ra internal surface finish

Operating Conditions

- Maximum operating pressure

- PG550/PG2400: 3.45 MPa/500

psig - PG11000: 1.72 MPa/250

psig

- PG550/PG2400: 3.45 MPa/500

- Maximum operating temperature:

- 100 °C/212 °F (INP, SIP, FCP, SF6P)

- 40 °C/104 °F (GEH4P, OXP, CLXP, HCLP, HBRP, CDAP)

- EU Pressure Equipment Directive: Assemblies have been evaluated for compliance with the European Union's Pressure Equipment Directive 2014/68/EU and are CE-marked.

1 VCR is a trademark of Swagelok Co.

Technical Information

Impurity Removal as Tested in Specific Gases| Specific Gas | Impurity Removal Efficiency |

| Inert gases: nitrogen, argon, helium, xenon, krypton, neon | <1 ppb H2O, CO2, O2, and CO, as tested in argon and nitrogen using APIMS analyzer |

| Flammable gases: silane, hydrogen, methane, ethane, cyclopropane, propane, dimethyl ether | <1 ppb H2O, CO2, O2, and CO, as tested in argon, nitrogen <1 ppb H2O, as tested in carbon monoxide using trace moisture analyzer H2O and siloxanes removed to trace levels, as tested in silane using APIMS |

| Carbon monoxide | <1 ppb Ni(CO)4, and < 1 |

| Fluorocarbons: fluoromethane, difluoromethane, trifluoromethane, |

<1 ppb H2O, CO2, O2, and CO, as tested in argon and nitrogen using APIMS analyzer <1 <10 ppb H2O, as tested in trifluoromethane using trace moisture analyzer and FTIR |

| Germane | <1 ppb H2O, CO2, O2, and CO, as tested in argon and nitrogen using APIMS analyzer |

| Sulfur hexafluoride | <1 ppb H2O, CO2, and O2, as tested in argon using APIMS |

| Oxygenated gases: carbon dioxide, oxygen, nitrous oxide, clean dry air | <10 ppb H2O <1 ppb H2O, and CO2, as tested in argon using APIMS analyzer |

| Chlorinated gases: boron trichloride, chlorine, trichlorosilane, dichlorosilane | <100 ppb H2O <1 ppb H2O, and CO2, as tested in argon using APIMS analyzer |

| Halogenated gases: hydrogen chloride, hydrogen bromide | < 15 ppb H2O as tested in hydrogen chloride using CRDS < 50 ppb H2O as tested in hydrogen bromide using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Photolithography clean dry air | < 1 ppb H2O as tested in argon using APIMS analyzer < 300 ppt C4H8 as tested in argon using APIMS Analyzer < 10 ppt SO2 as tested in nitrogen using ion < 15 ppt NH3 as tested in nitrogen using ion < 1 ppt HMDSO as tested in argon using APIMS analyzer and baseline subtraction |

Unit conversion: 1 bar = 100 kilopascals

Performance

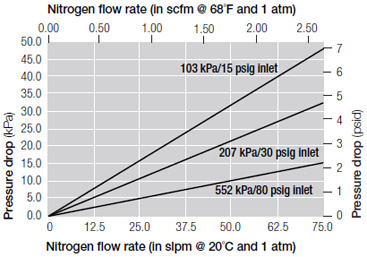

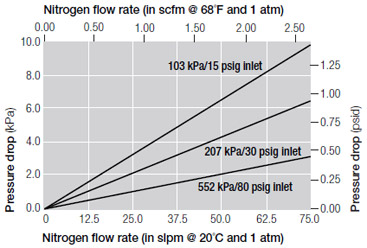

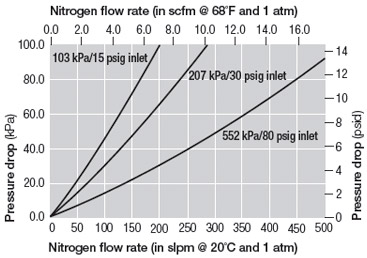

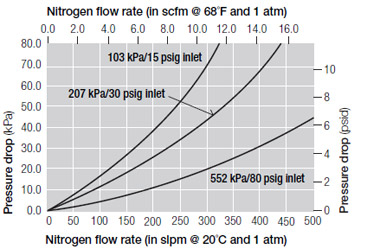

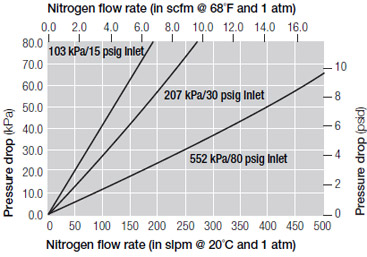

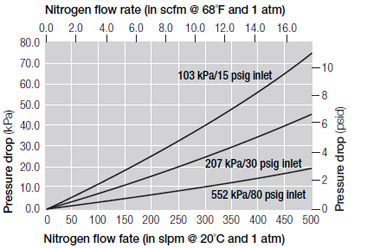

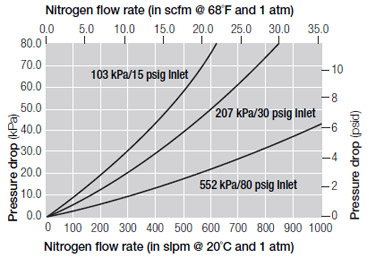

Pressure Drop vs. Gas Flow Rate

PG550 with 0.003 μm filter

PG550 with 0.4 μm filter

PG2400___VMM4 with 0.003 μm filter

PG2400___VMM4 with 0.4 μm filter

PG2400___VMM8 with 0.003 μm filter

PG2400___VMM8 with 0.4 μm filter

PG11000 Series assembly

Note: For pressure drop information for a specific application, please contact Pall Microelectronics.

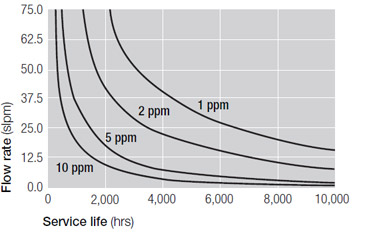

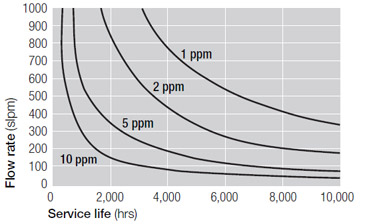

Lifetime Calculations

Pall AresKleenTM purification material: inert gas serviceGaskleen® PG550 purifier assembly, part # GLP9INPVMM4

Inlet pressure: 207 kPa (30 psig) contaminant challenge as H2O

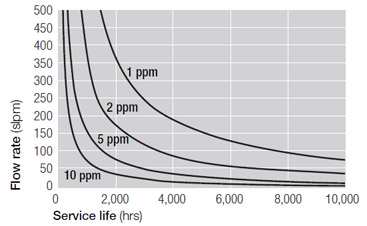

Pall AresKleenTM purification material: inert gas service

Gaskleen® PG11000 purifier assembly, part # GLP110INPVFM8

Inlet pressure: 207 kPa (30 psig) contaminant challenge as H2O

Pall AresKleenTM purification material: inert gas service

Gaskleen® PG2400 purifier assembly, part # GLP24INPVMM4/VMM8

Inlet pressure: 207 kPa (30 psig) contaminant challenge as H2O

Type

Systems

Additional Information

List of Purifiable Gases

| Gas Family | Material | Effluent Specification2 |

| Nitrogen, argon, helium, xenon, krypton, neon | INP | <1 ppb H2O, O2, CO2 and CO |

| Silane, hydrogen, methane, cyclopropane, propane, dimethyl ether | SIP | <1 ppb H2O, O2, CO2 and CO |

| Carbon monoxide | SIP | <1 ppb H2O, O2, CO2, Ni(CO4), and Fe(CO)5 |

| Fluoromethane, difluoromethane, |

FCP | <1 ppb H2O, O2, CO2 |

| Germane | GEH4P | <1 ppb H2O, O2, CO2 |

| Sulfur hexafluoride | SF6P | <1 ppb H2O, O2, CO2 |

| Air, carbon dioxide, oxygen, nitrous oxide | OXP | <10 ppb H2O |

| Boron trichloride, chlorine, trichlorosilane, dichlorosilane | CLXP | <100 ppb H2O |

| Hydrogen chloride | HCLP | <15 ppb H2O |

| Hydrogen bromide | HBRP | < 50 ppb H2O |

| Photolithography clean dry air | CDAP | < 1 ppb H2O, < 300 ppt organics (as C4), < 10 ppt acid gases (as SO2), < 15 ppt basic gases (as NH3), < 1 ppt refractory compounds (as HMDSO |

2 As tested in inert gas.

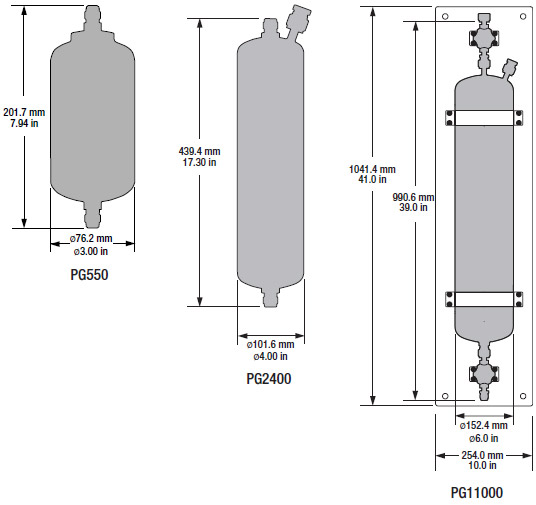

Nominal Assembly Dimensions

Note: For manifold dimensions, please contact Pall Corporation.

Ordering Information

| Series | Part Number3 | Description |

| PG550 | GLP9xxxxFVMM4 | Purifier assembly, 75 |

| GLP9xxxxFMAN | Bypass manifold with GLP9xxxFVMM4 assembly | |

| GLP9xxxxFVMM4GCMAN | Gas cabinet manifold with GLP9xxxFVMM4 assembly | |

| GLP9xxxxVMM4 | Purifier assembly, 75 |

|

| GLP9xxxxMAN | Bypass manifold with GLP9xxxVMM4 assembly | |

| GLP9xxxxVMM4GCMAN | Gas cabinet manifold with GLP9xxxVMM4 assembly | |

| PG2400 | GLP24xxxxFVMM4 | Purifier assembly, 300 |

| GLP24xxxxFVMM8 | Purifier assembly, 300 |

|

| GLP24xxxxFMAN | Bypass manifold with GLP24xxxxFVMM8 assembly | |

| GLP24xxxxVMM4 | Purifier assembly, 500 |

|

| GLP24xxxxVMM8 | Purifier assembly, 500 |

|

| GLP24xxxxMAN | Bypass manifold with GLP24xxxxVMM8 assembly | |

| PG11000 | GLP110xxxxVFM84 | Purifier assembly, 1,000 |

| GLP110xxxxMAN4 | Bypass manifold with GLP110xxxVMM8 assembly | |

3 See list of purifiable gases on page 1. Example: GLP9INPFVMM4.

4 The PG11000 stainless steel assembly (used with all GLP110 part numbers) is fabricated in accordance with the ASME BPVC Section VIII, Division 1, and has a U-stamp. If the user determines that an L-stamp is required for a lethal service application, please contact Pall Microelectronics for cost and availability.

Reviews

We appreciate your review of this product. Please login to your account to leave a review.