Documents

Datasheets

Download:Description

Pall's Mini Gaskleen gas purifier is a true point-of use purifier. A unique combination of Pall's cutting-edge AresKleen™ purification material and Ultramet-L® stainless steel filter media, it is designed to remove contamination from many process gases. The purifier is capable of sub ppb level purification at designed flow rates of up to 1 splm ,

- Controls and reduces impurities such as O2, H2O, CO2, CO, NMHC, Ni(CO)4 and Fe(CO)5

- One-for-one dimensional replacement of conventional in-line particle filter assemblies

- Assembly hardware is made of 316L stainless steel

High efficiency diffusion barrier ensuresintegrity of reactive material during installation- Superior pressure drop characteristics

- Purifies a wide variety of gases

- 100% helium leak and pressure tested

- Compact size

- Not orientation sensitive

- Does not generate hazardous waste when used in non-hazardous gas service

- Will not release hydrocarbons

- No detectable metal contribution above background in HCl gas with HCLP material

- No detectable metal contribution above background in HBr gas with HBRP material

Specifications

Materials

- Electropolished 316 L VAR PLUS stainless steel components

- ≤ 0.25 μm / 10 μin Ra internal surface finish

Particle Removal Efficiency Rating

- 1x109 retention of particles ≥ 3 nm up to 2 slpm

Connections

- 1⁄4 in. Gasket seal, male / male (VCR1 compatible)

Operating Conditions

- Maximum operating pressure: 20.7 MPa / 3,000 psig

- Maximum operating temperature:

- 100 °C / 212 °F (INP, SIP, FCP, SF6P)

- 40 °C / 104 °F (GEH4P, OXP, CLXP, HCLP, HBRP, CDAP)

- EU pressure equipment directive: Assemblies have been evaluated and designed using SEP per the European Union's Pressure Equipment Directive 2014/68/EU and are not CE marked

Design Flow Rate

- 0-1 slpm @ 0.1 MPa / 15 psig

- Higher intermittent flow rates of up to 2 slpm can be accommodated, with reduced lifetime2

Packaging

- Double bagged

- Outer bag: aluminized Mylar3

- Inner bag: polyethylene

- End fittings capped with metal seals

- Product packaged in an argon environment

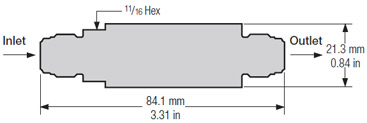

Dimensions

- Length: 84 mm / 3.31 in.

- Diameter: 21.3 mm / 0.84 in.

1 VCR is a trademark of Swagelok Company

2 Contact the Pall Microelectronics Group for further information.

3 Mylar is a registered trademark of Dupont Teijin Films.

Technical Information

Impurity Removal as Tested in Specific Gases| Specific Gas | Impurity Removal Efficiency |

| Inert gases: Nitrogen, argon, helium, xenon, krypton, neon | < 1 ppb H2O, CO2, O2 and CO, as tested in argon and nitrogen using APIMS analyzer |

| Flammable gases: Silane, hydrogen, methane, ethane, cyclopropane, propane, dimethyl ether |

< 1 ppb H2O, CO2, O2 and CO, as tested in argon, nitrogen and hydrogen using APIMS analyzer < 1 ppb H2O, as tested in carbon monoxide using trace moisture analyzer H2O and siloxanes removed to trace levels, as tested in silane using APIMS |

| Carbon monoxide | < 1 ppb Ni(CO)4, and < 1 ppb Fe(CO)5, as tested in carbon monoxide using GC-ECD analyzer |

| Fluoromethane, difluoromethane, trifluoromethane, tetrafluoroethane, pentafluoroethane, heptafluoropropane, carbon tetrafluoride, perfluoropropane, perfluorocyclobutane, hexafluoroethane | < 1 ppb H2O, CO2, O2, and CO, as tested in argon and nitrogen using APIMS analyzer < 1 ppb O2, as tested in trifluoromethane using trace oxygen analyzer < 10 ppb H2O, as tested in trifluoromethane using trace moisture analyzer and FTIR |

| Germane | < 1 ppb H2O, CO2, O2, and CO, as tested in argon and nitrogen using APIMS analyzer |

| Sulfur hexafluoride | < 1 ppb H2O, CO2, and O2, as tested in argon using APIMS |

| Oxygenated gases: Carbon dioxide, oxygen, nitrous oxide, clean dry air | < 10 ppb H2O < 1 ppb H2O, and CO2, as tested in argon using APIMS analyzer |

| Chlorinated gases: Boron trichloride, chlorine, trichlorosilane, dichlorosilane | < 100 ppb H2O < 1 ppb H2O, and CO2, as tested in argon using APIMS analyzer |

| Hydrogen chloride | < 15 ppb H2O as tested in hydrogen chloride using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Hydrogen bromide | < 50 ppb H2O as tested in hydrogen bromide using CRDS < 1 ppb H2O as tested in argon using APIMS analyzer |

| Photolithography clean dry air | < 1 ppb H2O as tested in argon using APIMS analyzer < 300 ppt C4H8 as tested in argon using APIMS Analyzer < 10 ppt SO2 as tested in nitrogen using ion chromatograph < 15 ppt NH3 as tested in nitrogen using ion chromatograph < 1 ppt HMDSO as tested in argon using APIMS analyzer and baseline subtraction |

Performance

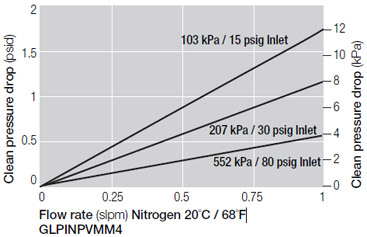

Pressure Drop vs. Gas Flow Rate

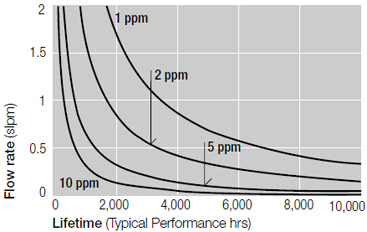

Lifetime Calculations

Pall AresKleen purification material: Inert gas serviceMini Gaskleen purifier assembly, part # GLPINPVMM4

Inlet pressure: 207 kPa (30 psig) contaminant challenge as H2O

Pall AresKleen purification material: Inert gas service

Mini-Gaskleen purifier assembly, part # GLPINPVMM4

Inlet pressure: 207 kPa (30 psig) contaminant challenge as O2

Type

Systems

Additional Information

Nominal Dimensions

Ordering Information

| Part Number | Specific Gas | Effluent Purity Specifications |

| GLPINPVMM4 | Inert gases: Nitrogen, argon, helium, xenon, krypton, neon | < 1 ppb H2O, O2, CO2, CO |

| GLPSIPVMM4 | Flammable gases: Silane, hydrogen, methane, ethane, cyclopropane, propane, dimethyl ether | < 1 ppb H2O, CO2, O2, CO |

| Carbon monoxide | < 1 ppb H2O, O2, CO2, Ni(CO)4, Fe(CO)5 | |

| GLPFCPVMM4 | Fluoromethane, difluoromethane, trifluoromethane, |

< 1 ppb H2O, CO2, O2 |

| GLPGEH4PVMM4 | Germane | < 1 ppb H2O, CO2, O2, CO |

| GLPSF6PVMM4 | Sulfur hexafluoride | < 1 ppb H2O, CO2, O2, CO |

| GLPOXPVMM4 | Oxygenated gases: Carbon dioxide, oxygen, nitrous oxide | < 10 ppb H2O |

| GLPCLXPVMM4 | Chlorinated gases: Boron trichloride, chlorine, trichlorosilane, dichlorosilane | < 100 ppb H2O |

| GLPHCLPVMM4 | Hydrogen chloride | < 15 ppb H2O |

| GLPHBRPVMM4 | Hydrogen bromide | < 50 ppb H2O |

| GLPCDAPVMM4 | Photolithography clean dry air | < 1 ppb H2O, < 300 ppt organics (as C4), < 10 ppt acid gases (as SO2), < 15 ppt basic gases (as NH3), < 1 ppt refractory compounds (as HMDSO) |

Unit conversion: 1 bar = 100 kilopascals

Reviews

We appreciate your review of this product. Please login to your account to leave a review.