Documents

Datasheets

Download:Description

Pall Microza1 Membrane Filtration Systems remove and concentrate all suspended solids from wastewater derived from silicon backgrinding (BG) and dicing (SD) operations.

Since only ultrapure water (sparged with C02) is typically used during backgrinding or dicing, the clear UF permeate can be readily reused as water feed.

The retained solids may be transferred to an existing sludge treatment system or to a dedicated system for final dewatering.

Pall can also provide fully automated turnkey installations, including recycle systems for producing SG process water from the permeate.

Since only ultrapure water (sparged with C02) is typically used during backgrinding or dicing, the clear UF permeate can be readily reused as water feed.

The retained solids may be transferred to an existing sludge treatment system or to a dedicated system for final dewatering.

Pall can also provide fully automated turnkey installations, including recycle systems for producing SG process water from the permeate.

1 Microza is a trademark of Asahi Kasei Corporation

Specifications

Technical Data

- Design Influent: Silicon backgrinding and/or dicing wastewater (BG and SD)

- Design TSS: Typically 500 mg/L (ppm) for BG; 50 mg/L for SD

- Operation Mode: Typically continuously fed batch

- Automation: Full automation via PLC and touch panel HMI

- Footprint (for standard 9 m3/h / 40 gpm): 2 m x 4 m (w/o buffer tank)

Performance Data

- Permeate Recovery: 95% - 99.8% of wastewater depending on operation mode and TSS in feed

- Permeate Turbidity: < 0.2 NTU

- Uptime: > 99%2

- Module Lifetime: > 1.5 years

- Cleaning frequency: < 2/year

- Operator Labor: < 15 min/day

- Chemical Dosage: none3

2 Uptime = (Volume of treated wastewater)/(Volume of available wastewater) x 100%

Not including chemical cleaning.

3 Except for occasional chemical cleaning.

Applications

Microza UNA module systems are designed to optimize the performance and extend the life of RO membranes.

Type

Systems

Additional Information

Options

Recommended Options to Base System

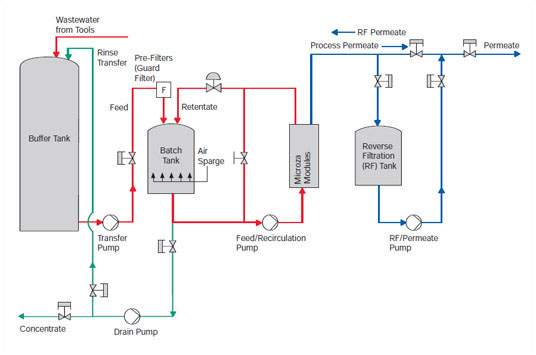

- Buffer Tank System: Provides holding capacity for changing feed flow rates and optimizes systems uptime. Typically 2+ hours holding capacity above volume required for normal processing

- Transfer Pump Systems: For transfer of wastewater from buffer tank to UF system, for draining and transferring concentrated solids to holding tank and for transfer and distribution of clarified water.

Additions

- Redundant membrane modules.

- N+1 Redundant Pumps: Add redundancy to wastewater transfer, recirculation, reverse filtration and concentrate pumps

- CIP Tank System: Enables preparation of cleaning solution without interrupting wastewater treatment.

- Chemical Dosing Stations: For automatic addition of chemicals for cleaning

- Concentrate Post Treatment: System for storage, destabilization and final dewatering of concentrated wastewater for solids disposal

- Permeate Post Treatment: System for processing of UF permeate to desired quality: e.g., by reverse osmosis or electrodeionization

- Service Contract: Routine on-site maintenance and remote monitoring to ensure optimized performance

- Remote control / Data transfer

Flow Schematic For Pall Microza Silicon Backgrinding/ Dicing Base System With Buffer Tank and Transfer Pump Option

Reviews

We appreciate your review of this product. Please login to your account to leave a review.