Documents

Datasheets

Download:Description

The Pall multistack high performance 316L stainless steel P-series housing can be designed and manufactured in accordance with A.D. Merkblatter or ASME Code. Pall's experience in housing manufacturing and filtration technology offers the user many benefits: crevice-free construction, easy-to-use closures, quick cartridge change, and 145 psi / 10 bar gauge working pressure at temperatures up to 365 ºF / 185 ºC. These housings are designed and manufactured by Pall to quality standards which are approved to ISO 9001 (BS 5750 part 1).

- Ideal for DI Water filtration

- Large vent connection for rapid venting

- All fluid contact surfaces manufactured from 316L stainless steel

- Glass beaded and passivated surface finish provides maximum resistance to corrosion and good cosmetic appearance

- Quick cartridge changeout

- Hydrodynamically designed inlet and outlet connections ensure excellent flow characteristics

- Large drain located upstream to minimize fluid hold-up volume

Specifications

Materials of Construction

- Shell, Head, and Tubesheet: 316L stainless steel

- Rathmann Clamps: Veralit nickel plated carbon steel

- Clamp Mounting Ring: 304 stainless steel

- Legs: 304 stainless steel

- Foot Pads: 304 stainless steel

Configurations

- Inlet/Outlet Connections: 80-200 mm BS4504 T16 flange, 2-8 in. ANSI flange options

- Vent/Drain: 1/2 in. BSPT male, 1/2 in. NPT

- Cartridge Adapter: Code 3, 7, or 8

Operating Conditions

- 145 psi @ 302 °F / 10 bar @ 150 °C for EPR gaskets

- 145 psi @ 365 °F / 10 bar @ 185 °C for Viton1 gaskets

Cartridge Capacity

- 5-around

- 12-around

- 31-around

Cartridge Lengths Accepted

- 20 in. / 508 mm, 40 in. / 1016 mm

Cartridge Configurations Accepted

- Code 3 - two 222 O-rings, flat end cap

- Code 7 - two 226 O-rings, locator fin, bayonette lock

- Code 8 - two 222 O-rings, locator fin

Design Options

A.D. MerkblatterASME Code U Stamp

Electropolishing available

Connections Available

- 2 in., 3 in., 4 in., 6 in., and 8 in. ANSI flange

- 80 mm, 100 mm, 200 mm BS4504 T16 flange

1 Viton is a trademark of DuPont Dow Elastomers.

Other options available - please contact Pall Microelectronics for details and ordering information.

Performance

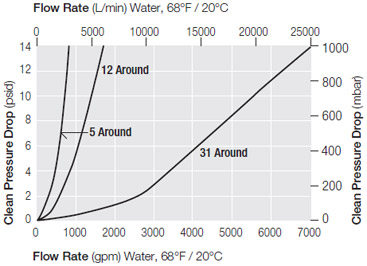

Pressure Drop vs. Liquid Flow Rate2

2 The liquid flow/pressure drop characteristics refer to the empty housing only for water at 20ºC / 68°F. For other liquids, multiply pressure drop by the specific gravity.

Unit conversion: 1 bar = 100 kilopascals

Type

Housings, Vessels, or Assemblies

Additional Information

Housing Drawing

Reviews

We appreciate your review of this product. Please login to your account to leave a review.