Documents

Datasheets

Download:Description

The Pall Kleen-Change® RRC Assembly is available with 0.2 μm, 0.45 μm, 1 μm and 3 μm retention ratings. The Kleen-Change RRC assembly offers a combination of proprietary PTFE membrane and specially engineered PTFE support material to provide superior flow performance for these sub-micron rated filters.

The Kleen-Change RRC assembly is a completely disposable filter unit that combines all fluoropolymer filter with Pall's all PFA housing. This provides a high flow disposable assembly option for today's demanding chemical applications. Designed for use where high flow, high pressure or high viscosity fluids require sub-micron retention.

Its unique configuration allows for safe, quick, and easy filter change outs while providing low hold-up volume and easy venting, thus reducing chemical waste and virtually eliminating the presence of air bubbles in the process.

- All high purity fluoropolymer materials

- Low extractable

- Compatible with virtually all chemicals1

- Excellent filter cleanliness

- Very high flow rates

- 100% integrity tested

- Low hold-up volume for reduced chemical waste

- Easy venting for minimizing air bubbles

- Easy installation / change out

- Minimal chemical exposure during capsule change-out

Operating Recommendations

-

As the filter media is hydrophobic, it is required to be prewet prior to filtering the process fluid. It is recommended to use extremely clean alcohol which is to be flushed with D.I. water prior to filtering inorganic chemicals. For applications where isopropyl alcohol (IPA) & D.I. water are not compatible with the process fluid, compatible solvents with relatively low surface tension (less than approximately 40 dyne/cm) such as NMP, DMF and DMAC, etc. may be used as a prewetting fluid.

For Prewetting the filter media, alcohol or compatible solvent is to be poured from the upstream connection to maintain the cleanliness of the downstream.

- Must allow for proper venting

- Pulse dampening should be designed into the system

- Preheating of high viscosity liquids should be designed into the system

Specifications

| Components | Materials |

| Medium | PTFE |

| Cartridge Hardware | High purity PFA |

| Support | PTFE |

| Housing | High purity PFA |

| O-ring | Perfluoroelastomer |

| Removal Rating | 3 μm, 1 μm, 0.45 μm, 0.2 μm |

| Connections Inlet Vent / Outlet Vent |

1⁄4" Male Super Pillar2 S300 / 3⁄8" Male Super Pillar S300 |

| Maximum Forward Differential Pressure |

0.4 MPa @ 40 ˚C / 58 psid @ 104 ˚F 0.2 MPa @ 100 ˚C / 29 psid @ 212 ˚F |

1 Consult Pall Microelectronics for recommendations for Hot Phosphoric or Hot Sulfuric, SPM, above 90˚C.

2 Pillar is a Trademark of Pillar Packing Co.

Performance

Typical Flow Characteristics - 1cP fluid (20℃)

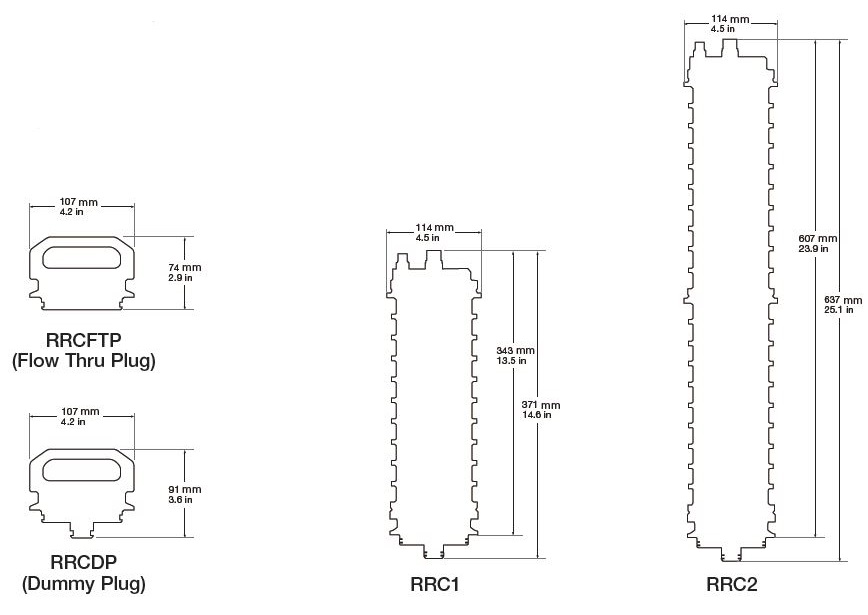

Dimensions

Type

Ordering Information

RRC[1]F[2][3]64E71[4]

Table 1

| Code | Nominal Length (mm / in) |

| 1 | 371 / 14.6 |

| 2 | 637 / 25.1 |

Table 2

| Code | Flow |

| L | Standard |

| M | High Flow |

Table 3

| Code | Removal Ratings |

| 020 | 0.2 μm |

| 045 | 0.45 μm |

| 100 | 1 μm |

| 300 | 3 μm |

Table 4

| Code | O-ring Materials |

| H11F | Perfluoroelastomer |

| H36 | Fluoroelastomer |

64E71 : Female Super Pillar S300 Vent connections

Upstream : 1/4”, Downstream : 3/8”

Reviews

We appreciate your review of this product. Please login to your account to leave a review.