Order Products

Industries

Biotech

MBS1001P05H

1/EA

1

MBS1001P05H13

1/EA

1

Nexis, NXA, 10 μm, 25.4 cm (10 in), DOE industrial (no end caps)

30/EA

30

Nexis® A Series Filter Cartridges, Removal Rating 1 μm, Polypropylene, Length 30 inches, silicone, SOE fin end external 222 O-rings

12/EA

12

Nexis® T Filter Cartridges, Removal Rating 1 μm, Polypropylene, Length 10 inches

30/EA

30

Nexis, NXT, 40 μm, 25.4 cm (10 in), SOE fin end, external 226 O-rings (retrofits other manufacturers’ Code 7), Silicone gasket

1/EA

1

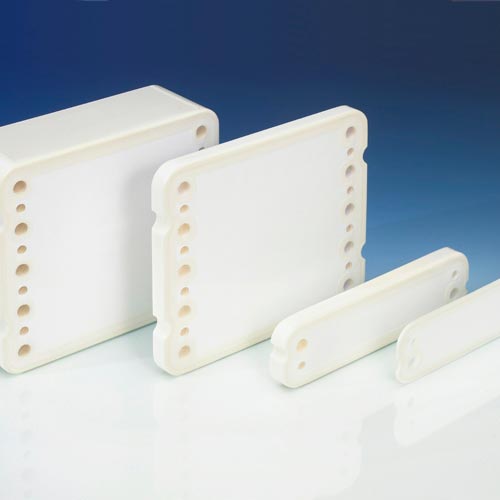

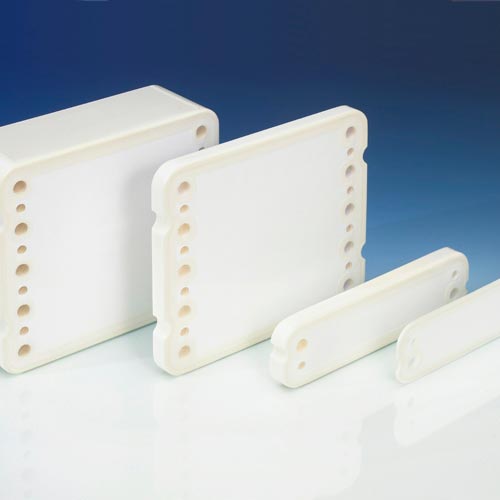

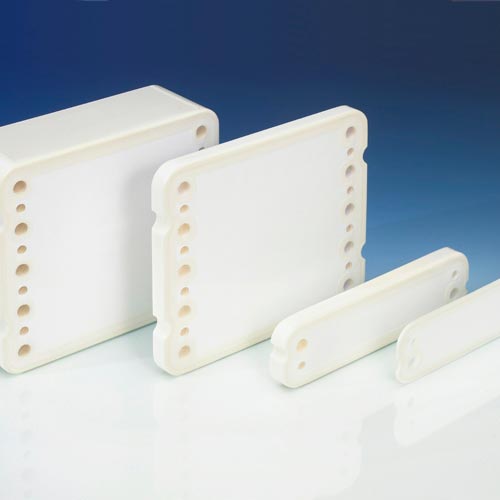

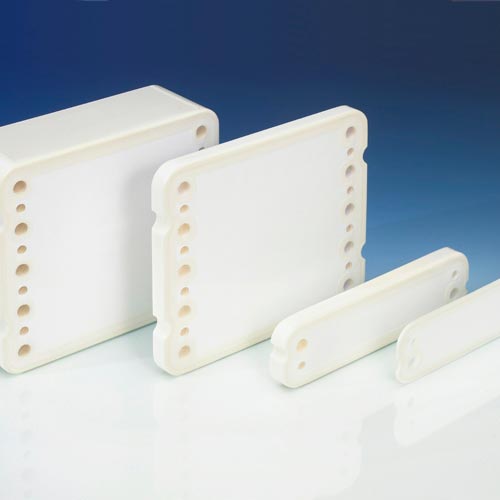

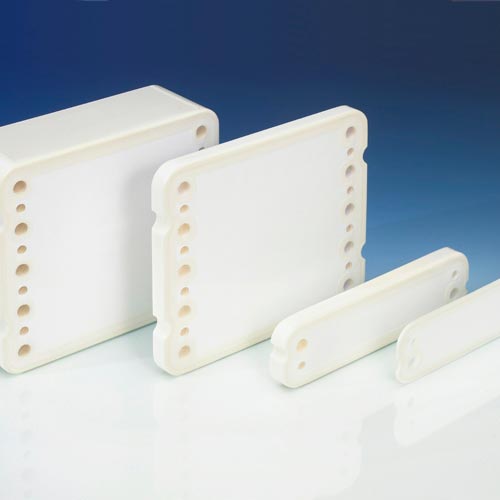

T-series Centramate™ Cassette, Omega PES membrane, 3 kDa molecular weight cut-off (MWCO), 0.1 m² effective filtration area (EFA)

1/EA

1

T-series Centramate™ Cassette, Omega PES membrane, 1 kDa molecular weight cut-off (MWCO), 0.02 m² effective filtration area (EFA)

1/EA

1

T-series Centramate™ Cassette, Omega PES membrane, 1 kDa molecular weight cut-off (MWCO), 0.1 m² effective filtration area (EFA)

1/EA

1

T-series Centramate™ Cassette, Omega PES membrane, 5 kDa molecular weight cut-off (MWCO), 0.02 m² effective filtration area (EFA)

1/EA

1

T-series Centramate™ Cassette, Omega PES membrane, 5 kDa molecular weight cut-off (MWCO), 0.1 m² effective filtration area (EFA)

1/EA

1

T-series Centramate™ Cassette, Omega PES membrane, 30 kDa molecular weight cut-off (MWCO), 0.02 m² effective filtration area (EFA)

1/EA

1