50 Results of 50 total products

Datasheets

Download:Poly-Fine II cartridges are a proven filter solution for consistent and effective particle removal in liquid food and beverage applications.

Description

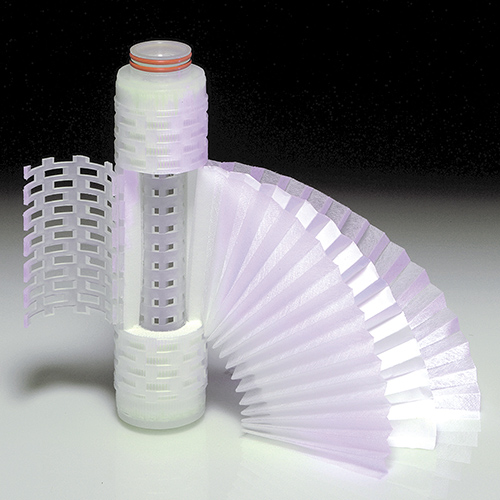

The Poly-Fine II element is a high area, pleated all-polypropylene depth filter frequently used in a wide variety of applications for particle removal. It is a cost-effective choice for final particle removal, or for pre-filtration, including reliable protection of final membrane filters.

Poly-Fine II filter media is the result of the latest in Pall proprietary technology and application expertise. Poly-Fine II media features a highly consistent pore structure with narrow pore size distribution, making it ideally suited for the capture of non-deformable contaminants, particulary those characterized by relatively narrow particle distribution.

Features and Benefits

| Features | Benefits |

| Proprietary melt blown, pleated media with high dirt holding capacity |

|

|

|

|

|

| Component | Description |

| Filter Medium | Polypropylene |

| Cage, Core, Find End and End Cap | Polypropylene |

| SOE Style Cartridges only Adaptor |

Polypropylene |

| O-ring Seal | Silicone Elastomer Ethylene Propylene Rubber |

| DOE Style Cartridges only Gasket |

Ethylene Propylene Rubber |

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Technical Information

The technical information provided is based on controlled laboratory tests done on typical production filters at the conditions described, unless otherwise indicated. Actual operating conditions may affect the filter's performance.

Operating Characteristics1

| Maximum Differential Pressure2 | Operating Temperature |

| 4.8 bard (70 psid) (forward) | 20 °C (68 °F) |

| 2.8 bard (40 psid) (forward) | 65 °C (150 °F) |

1Fluids which do not swell, soften or adversely affect any of the filter components

2Recommended change-out differential pressure is 2.4 bard (35 psid), provided the maximum differential pressure (based on temperature) is not exceeded.

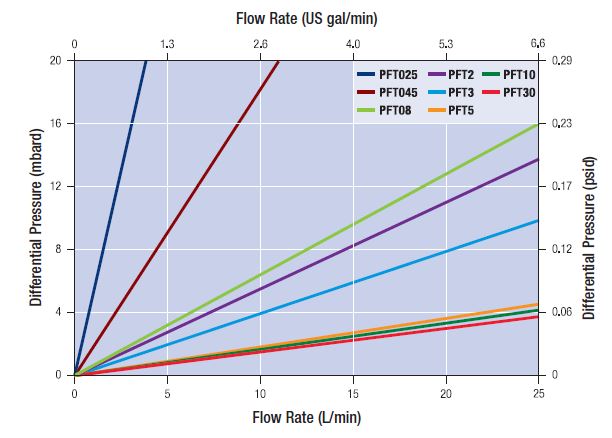

Typical Flow Rates3

3Typical initial clean delta p per 254 mm (10 inch) cartridge, water at 20° C (68° F). For liquids with viscosity greater than 1cP, multiply the delta p by the viscosity.

Sterilization and Sanitization

Multiple autoclaving for 30 minutes at 1 bar (15 psig) steam (121 °C /250 °F) under no end load conditions, up to 10 cycles. In-line steam sterilization is not recommended. May be in-line sanitized with hot water at 82 °C (180 °F) for 1 hour.

Ordering Information

This information is a guide to the part numbering structure and possible options. For availability of specific options please contact Pall. Refer to Pall for housing details.

Part Number: PFT [Table 1] [Table 2] U [Table 3] [Table 4] W 480

Example Part Number:PFT02530USM7W480

See bold reference code in tables.

Table 1:Removal Rating4

| Code | Description | |

| 90% Efficiency (Beta 10) | >99.9% Efficiency (Beta 1000) | |

| 0.25 | 0.25 μm | 1 μm |

| 045 | 0.45 μm | 1.2 μm |

| 08 | 0.8 μm | 2.5 μm |

| 2 | 2 μm | 5 μm |

| 3 | 3 μm | 7 μm |

| 5 | 5 μm | 12 μm |

| 10 | 10 μm | 15 μm |

| 30 | 30 μm | 40 μm |

4Poly-Fine II filter cartridge liquid retention ratings are determined by a single pass test based on ASTM F-795 (see Pall Technical Bulletin 1903-4T). Removal efficiencies are shown at the stated rating in compatible fluids.

Table 2: Nominal Length

| Code | Description |

| DOE Style only: | |

| 975 | 248 mm (9.75") |

| 10 | 254 mm (10") |

| 195 | 495 mm (19.5") |

| 20 | 508 mm (20") |

| 2925 | 743 mm (29.25") |

| 295 | 749 mm (29.5") |

| 30 | 762 mm (30”) |

| 39 | 991 mm (39") |

| 40 | 1016 mm (40") |

| SOE Style only5: | |

| 10 | 254 mm (10") |

| 20 | 508 mm (20") |

| 30 | 762 mm (30") |

| 40 | 1016 mm (40") |

5Please contact Pall for specific dimensions of SI option cartridges.

Table 3: O-Ring / Gasket Seal Material

| Code | Description |

| S | Silicone Elastomer6 |

| E | Ethylene Propylene Rubber |

6for M3, M7, M8 options only

Table 4: Adaptor

| Code | Description |

| Blank | DOE – with open end caps/gasket |

| M3 | SOE – single open end with flat closed end and external 222 O-rings |

| M7 | SOE – single open end with fin end, 2 locking tabs, and external 226 O-rings |

| M8 | SOE – single open end with fin end and external 222 O-rings |

| SI | SOE – with open end cap/gasket and integral stainless steel spring on flat closed end |

We appreciate your review of this product. Please login to your account to leave a review.