The Window to Your Fluid System's Health. Use as part of your Diagnostics, Prognostics and Health Management.

- Provides advance warning of impending component failure

- Captures metallic and non-metallic debris

- Allows for on-site inspection of wear debris of interest

Aircraft maintenance personnel want to know the condition of the fluid system and to receive advance warning of any impending component failure.

The Dirt Alert diagnostic layer provides a simple way of viewing and capturing the debris of diagnostic interest. It can assist operators in preventative maintenance, both during flight and on the ground during "Green Run" testing of engines.

Features

- Diagnostic layer is easily removed on-site

- Diagnostic layer can be retained as evidence of Green Run Filter use and/or engine cleanliness

- Captures both metallic and non-metallic debris

- Samples full system flow (more likely to capture the larger wear debris)

Benefits

- Early detection reduces the impact of component failure on system performance and secondary damage to other system components

- Reduces overall maintenance

- Differentiates characteristic wear debris from normal debris

- Augments other engine diagnostic tools

- Quicker and easier to inspect than traditional filter elements

The Dirt Alert filter element design is flight worthy and can be flight qualified for the specific platform. Note that ‘Green Run’ Dirt Alert filter elements are very fine (typically 3 micron), and, although flight worthy, are generally not recommended for flight due to the potential for short filter element service life.

How does a Dirt Alert filter element work?

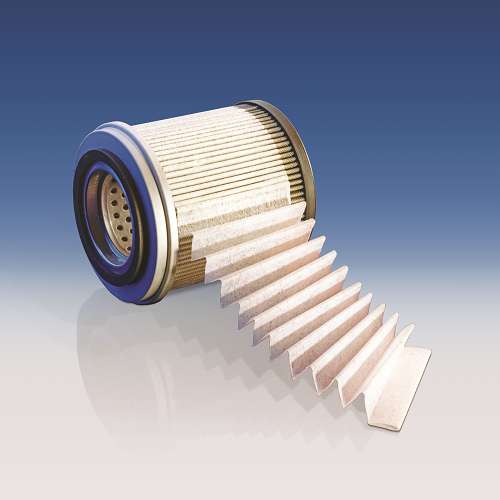

The 'Dirt Alert' element incorporates a pull-out diagnostic layer of porous medium in conjunction with regular filtration medium. The diagnostic layer can be removed after a certain period in service, or after engine ‘Green Run’ for new engines.

The diagnostic layer can be examined on site to observe if there are any large wear debris of diagnostic value. Wear debris of interest can be easily removed from the diagnostic layer for additional characterization by various analytical techniques (e.g., x-Ray fluorescence spectroscopy, Scanning Electron Microscope/x-Ray Emission Spectroscopy, etc. The 'Dirt Alert' diagnostic layer can be retained as part of the maintenance record.

What are Green Run Filter Elements?

After an engine is built, or overhauled, it is run for the first time in the test cell – the Green Run.

Green Run filter elements remove contaminants built-in during the system manufacturing process and break-in wear debris generated during start-up and engine calibration (Green Run) to ensure the fluid system is clean before delivery. Primarily used for lubrication systems, Green Run filter elements are fine, typically rated at 3 µm.

Use of Green Run Filters has been proven to improve reliability of critical components such as bearings and gears.

Pall's Dirt Alert filter elements are used in

- Engine Lube Systems

- Helicopter Transmission Lube systems

Civil engine Green Run applications include CFM56 series, JT8D, PW2000, PW4000, PW6000, and GTF™

Literature and Other Resources

Condition monitoring of aerospace hydraulic and lubrication systems via filter debris analysis.

Each product is designed and tailored to meet the customer specification requirements. If you have an aerospace application that needs a diagnostic filter element, please talk to one of our experts Contact Aerospace.

For commercial aircraft products, please contact our authorised distributor Satair.

We appreciate your review of this product. Please login to your account to leave a review.