In addition to PAC's traditional line of Rigimesh® last chance filters, we have developed and can now offer a line of laser drilled filters rated for 70-microns nominal and larger which can be used in those applications where a high collapse pressure or burst pressure requirement exists.

The laser drilled filter is most effective when there is a bi-directional flow requirement in a very restricted envelope. Conventional mesh-type filters are not suitable for these applications because they require support cores in addition to multiple layers of mesh resulting in a costly filter with high pressure drop.

The laser drilled filter can also be used for washflow filter applications with ratings in the 70-micron range and in other geometries where the pressure drop is considered critical. The laser drilled filters offer excellent wash flow and superior flow versus pressure drop characteristics.

The laser drilled filter can generally be designed into either a single-piece or two-piece assembly where reliability, weight and strength of construction are critical.

In addition to the selection of laser drilled filters we depict in this section, PAC can supply laser drilled versions of most of the other type for LCFs pictured in the catalog.

PALL AEROPOWER P/N 31001LD[G]E[G]

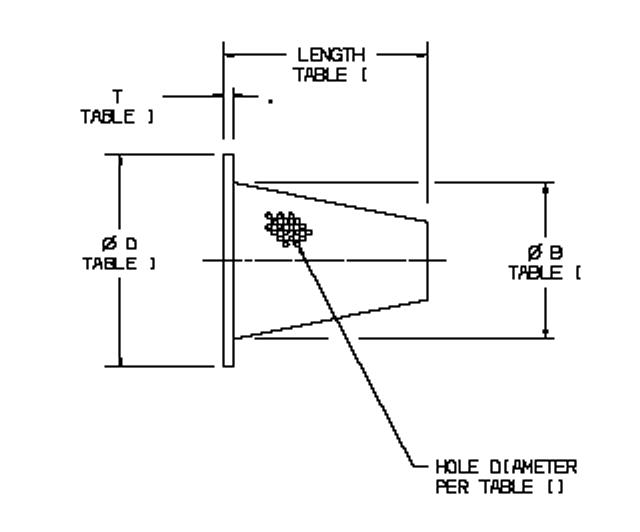

STRAINER, HIGH PRESSURE, FLANGE MOUNT

TABLE I

| Size Code | Ø D | T | Ø B Max. | Length | Min. Area |

|---|---|---|---|---|---|

| 03 | .129 - .132 | .012 - .018 | .120 | .123 | .02 |

| 04 | .225 - .229 | .013 - .017 | .175 | .200 | .05 |

| 05 | .324 - .330 | .014 - .019 | .250 | .300 | .15 |

| 06 | .375 - .385 | .014 - .019 | .295 | .36 | .23 |

| 08 | .493 - .498 | .018 - .023 | .380 | .49 | .75 |

| 10 | .669 - .674 | .024 - .029 | .500 | .73 | .75 |

TABLE I I

| | |||

| Hole Size Code | Nominal Hole Size | (Percent Open Area) | (Micron Rating) |

|---|---|---|---|

| 003 | 0.003 | 12 | 75 |

| 004 | 0.004 | 18 | 100 |

| 006 | 0.006 | 18 | 150 |

| 008 | 0.008 | 18 | 200 |

| 010 | 0.010 | 18 | 250 |

| 015 | 0.015 | 22 | 380 |

NOTES AND SPECIFICATION:

- CONFIGURATION IAW TABLE I.

- NOMINAL FILTRATION RATING IAW TABLE II.

- MINIMUM ELEMENT COLLAPSE OR BURST DIFFERENTIAL PRESSURE: 7500 PSID.

- SINGLE PIECE CONSTRUCTION.

- MATERIAL: 17-4 PH CONDITION H925 SST PER AMS 5643.

- FINISH: PASSIVATE PER AMS-QQ-P-35.

- EXAMPLE PN: "31001LDO8E004" SPECIFIES THIS STYLE OF FILTER ELEMENT THAT IS 08 SIZE PER TABLE I, WITH Ø.004 FILTERING HOLES.

- MINIMUM TOTAL AREA OF FILTERING SURFACE: SEE TABLE I.

We appreciate your review of this product. Please login to your account to leave a review.