Description

Located upstream of the engine to prevent damaging contamination entering the air system. Benefits include:

- Increased engine MTBUR for erosion

- Reduced unscheduled engine removals

- Reduced cost of component repairs

- Reduced logistics burden (cleanable)

- Increased operational flexibility

Military vehicles operate in an intensely challenging environment and the engine air intakes are frequently battered by airborne contamination, e.g. dust, sand and heavy rain. If this contamination enters the engine air system it can lead to the following problems

- Wear on turbocharger

- Bearing wear

- Damage to air system components

- Heavily Contaminated Oil

- Damage to valves, piston rings, cylinder liners

All of these lead to loss of power/torque reduction.

Depending on the operational environment, they can also significantly decrease an engine’s Mean Time Between Unscheduled Removals (MTBUR).

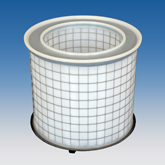

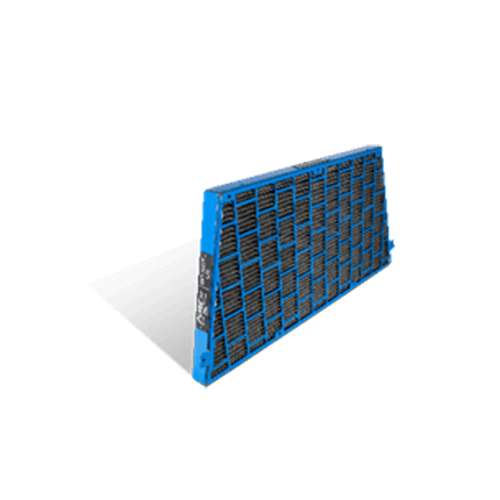

Barrier filter elements are used to protect air systems and their components from airborne contamination. By removing damaging wear particles, these filters enhance equipment reliability, availability, and performance.

Barrier Filter Features

- Bi-Pleat, Quadra-Pleat and Cylindrical designs

- Cleanable or disposable filter elements are available

- Not affected by moisture

- High particulate removal efficiency

- Quick and simple change out

Benefits of Pall cleanable barrier filter elements

- No need for special chemicals, oils or cleaning equipment

- Reduce the logistics burden (no need to carry spare filters)

- Extend your operational reach

Applications

Pall has extensive experience in providing Engine Air Protection Systems to military fighting vehicles, with multiple systems in service throughout the world. Other applications include:

- Military Vehicle Diesel Engine Air Intakes

- Helicopter Engine Air Intakes

- Aircraft Cabin Air systems

Type

Use

Ordering Information

Here to help

If you have a military vehicle program that needs a barrier filter element, please talk to one of our experts Contact Aerospace.Reviews

We appreciate your review of this product. Please login to your account to leave a review.