Save money with the Pall portable purifier

Hydraulic, lubrication, and cooling fluids account for a significant part of annual operating costs. Operators therefore require a process to extend fluid service life and also reduce the procurement and disposal costs due to waste fluids.The Pall purifier solves the problem and unlike centrifuges and coalescers, it removes both FREE and DISSOLVED water. The HNP006++YK30 variant was specifically designed to be installed on ships.

Features

The fluid purifier removes:- 100% Free water and entrained gases

- Up to 90% Dissolved water and gases

- Fine particulate, using a high performance (ß5(c)≥1000) filter element

- Fits through a ship’s hatch

- Simple automated operation

- Low power consumption

- In-built water sensor (optional)

- Heater option available for low temperature, high viscosity fluids

Benefits

- Extends fluid service life

- Reduces fluid disposal costs

- Minimizes corrosion within systems

- Visual display of system water content

- Increases system performance and equipment reliability

- Reduces maintenance costs

The marine version is a compact design to allow for ease of handling through restricted openings. It can be located close to existing systems where space is limited.

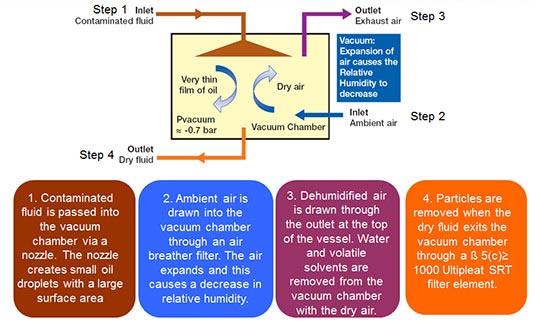

How Does it Work

The Pall portable purifier removes water, air, and volatile solvents using a vacuum dehydration process. It removes solid particulate contaminant using a high-efficiency filter element.

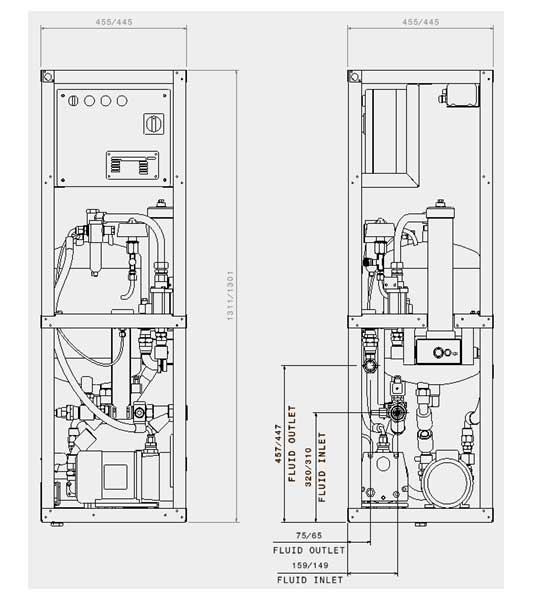

| Dimensions: L x W x H |

455 X 455 X 1311 mm (17.9 x 17.9 x 51.6 “) |

| Dry weight: | 80Kg (176 lb) |

| Inlet connection: | G1-1/4 Thread |

| Outlet connection: | G1 Thread |

| Circulation flow rate: | 10L/min at 50hz (2.6 US gpm) 12.5L/min at 60Hz (3.3 US gpm) |

| Total motor power: | 0.72Kw |

| Maximum viscosity (at purifier): |

700Cst |

| Ambient Service Temperature: |

+10ºC (50ºF) to +70ºC (158ºF) |

| Max pressure for inlet: | 10barg (145psig) |

| Max pressure for outlet | 7 bar g maximum (101 psig) |

| Normal operating vacuum: |

-0.6barg to -0.9barg (-8.7psig to -13.1 psig) [adjustable] |

| Material Construction | |

| Base frame, vessel: | Stainless Steel |

| Threaded Fittings and Fasteners | Zinc Plated Carbon Steel |

| Control box | Polycarbonate |

| Hose | Fluorocarbon |

Oil Purifiers

Purification

Part number: HNP006 [1] [2] [3] [4] [5] YK30

Example part number: HNP006 N7+AHN YK30

Example part number: HNP006 N7+AHN YK30

Table 1: Voltage

| Code | Voltage Characteristics |

| N | 230 Vac, 24 Vdc Control Circuit |

Table 2: Electrical Frequency

| Code | Frequency Characteristics |

| 7 | 50/60Hz |

Table 3: Outlet filter Rating

| Code | Rating (ISO16889) | Important |

| +A | No Filter Fitting | Unit must be installed prior to running |

Table 4: Seals

| Code | Seal Material | Test Fluid |

| H | Fluorocarbon | Mineral Oil |

Table 5: Mounting

| Code | Mounting | Outlet Filter Length | Other options |

| D | Static | 14 in. | --------- |

| N | Water Sensor | ||

Outlet Element Ordering Information

Part number: UE219 [Rating Code] [Length Code] [Seal Code]| Rating Code | Rating (ISO 16889) | Max Service Viscosity | Length Code | Seal Code |

| AP | ß 5(C) ≥ 1000 | 700 cSt 3300 (SUS) | 13 | H |

| AN | ß 7(C) ≥ 1000 | |||

| AS | ß 12(C) ≥ 1000 | |||

| AT | ß 22(C) ≥ 1000 | |||

We appreciate your review of this product. Please login to your account to leave a review.