Sustainable solution to reduce fluid maintenance costs

- Extends fluid service life (reduces new fluid procurement costs)

- Reduces fluid waste stream

- Reduces fluid disposal costs

- Increases system performance, reliability and maintainability

- Reduces downtime and servicing man-hours (i.e., drain and flush operations)

Portable Purification Systems Maximise System Reliability and Reduce Maintenance Costs

Features

- Removes 100% of free water and over 80% of dissolved water (less than 100ppm dissolved water in hydraulic fluid)

- Removes 100% of free and entrained gases and up to 80% of dissolved air/gases

- High-Efficiency Particulate Removal Filter: 3-micron absolute filter, β3 [5(c)] ≥ 1000

- Easy to connect, simple to operate, and requires minimum operator attention

- Operates under vacuum conditions without heating the fluid

System Reliability

Proven system with thousands of units deployed globallyEasily Portable

Small and lightweight. Mounted on wheels for high mobility. Rear wheel locksUnattended Operation

Full PLC control designed for automatic, unattended operation.Automatic controls will safely shut down and protect the system if fluid levels and pressures exceed normal limits.

No controls to set, no adjustments to make

Benefits

- Extends fluid service life (reduces new fluid procurement costs)

- Reduces fluid waste stream

- Reduces fluid disposal costs

- Increases system performance, reliability and maintainability

- Reduces downtime and servicing man-hours (i.e., drain and flush operations)

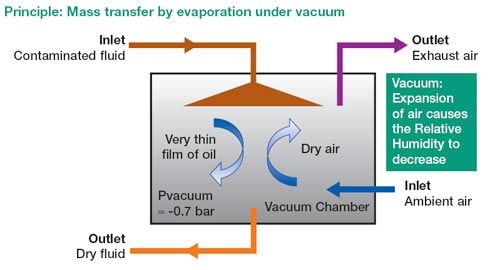

How Does a Pall purifier Work?

The Pall portable purifier removes water, air, and volatile solvents using a vacuum dehydration process. It removes solid particulate contaminant using a high-efficiency filter element.Pall supplies several different versions of the fluid purifier. They all use the same basic principle to remove water and contamination; the only difference is in the method of oil dispersion within the vacuum chamber of the purifier.

Pall supplies the spinning disc type of purifier in different configurations to meet a variety of power requirements.

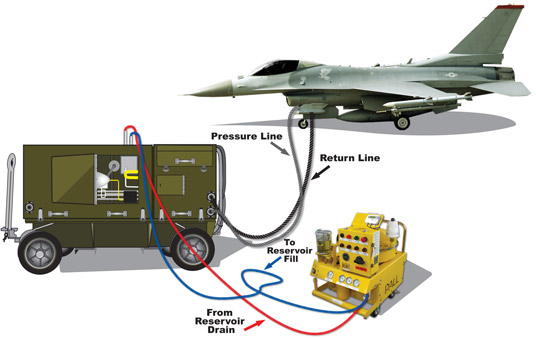

Aircraft Connection

Typically, the unit is connected to the aircraft via the hydraulic test stand (hydraulic mule). Pall also supplies a purifier that is suitable for direct connection into the aircraft. Pall HSPA Hydraulic Fluid Purifier for Aircraft Maintenance.

For technical data, please see the product datasheet.

- Hydraulic fluids

- Lubrication fluids

- Electronic coolant fluids

- It is NOT suitable for recycling fuel

Oil Purifiers

Purification

For price and availability, please talk to one of our experts Contact Aerospace.

Typical Part Numbers

The purifier part numbers beginning PE01090*** or, PE01078***, are made at our facility in Florida, USA.

We appreciate your review of this product. Please login to your account to leave a review.