Optimized designs using our knowledge of Fuel, Lube and Hydraulic, and Liquid Coolant filtration systems

- Compact packaging and low weight

- High Reliability

- Qualified using in-house test facilities

- OEM approved

Maintaining a specified level of fluid cleanliness is critical to the operation and reliability of aerospace fluid systems and equipment.

A filter assembly consists of a filter housing and a high-performance filter element. Where specified, it can include bypass valves, non-return valves, differential pressure monitoring devices, and other sampling points.

Features

- Incorporates high performance filter elements using Pall proprietary media

- High-strength construction

- Filter Bowl & Filter Head meet fatigue and pressure requirements (dependant on application)

- Low differential pressure

- Bowl-locking mechanism to prevent filter bowl loosening under vibration in service

- Electro-Static Discharge (ESD) pin

Benefits

- Light-weight designs

- Small space envelope

- Improved system performance and reliability

- Qualified to stringent OEM requirements

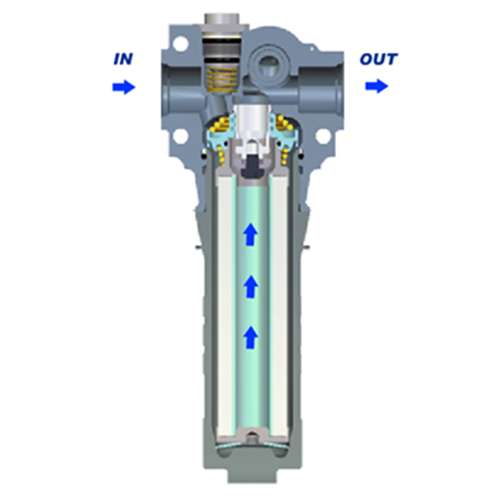

Aerospace filter assembly cross-section

The system fluid enters the assembly through the inlet port. It flows through the inlet and into the filter element.

- Filter Element

Particulate contamination including metals, dust, fibers, seal material, etc., is removed and captured by the filter element. The clean fluid then exits the assembly through the outlet port. - Electro-Static Discharge (ESD) pin

Some fuel filter elements include Pall’s patented ESD pin. This feature dissipates any charge build-up and prevents component damage due to electrostatic discharge.

Click for more information on Electro-Static Discharge (ESD) in industrial systems - Monitoring Devices/Sensors

After a period of service, the element will become loaded with contamination and require replacement. The Differential Pressure Indicator/Switch (DPI/DPS) located in the head of the filter assembly indicates when the filter element is becoming plugged with contamination and needs to be changed.

A thermal lockout device (optional) prevents false indication at cold start conditions. - Bypass Valve

If the element is not changed, the filter element differential pressure will continue to rise. Above a certain value, the bypass valve opens and the fluid by-passes the filter element and passes directly to the outlet port. - Shut-Off Diaphragm (optional)

This prevents loss of fluid during element change-out.

Pall’s filter assemblies are qualified for a wide variety of systems:

- Engine Lube

- Engine Fuel

- Hydraulic

- Helicopter Gearbox Transmissions

- Radar Cooling

- Liquid Coolant Systems

We have decades of experience providing filtration solutions for commercial and military aerospace programmes. Each design is unique to the application – below are a few examples of the wide range of filter assemblies that Pall has qualified.

|

|

|

Literature and Other Resources

Mi8, 17, 24/35 Helicopters: Improving Reliability and Availability

Do you want to know more about Aerospace Filtration? We can help Watch our Filtration 101 webinar to learn about

- How to increase system reliability

- Typical reasons for component failure

- Importance of fluid cleanliness

- How to correctly specify a filter

- How filters are tested to demonstrate their performance

- And more…

Our filter assemblies are designed and tailored to meet the customer specification requirements.

If you have an aerospace application that needs a high performance filter assembly, please talk to one of our experts Contact Aerospace

For commercial aircraft products, please contact our authorised distributor, Satair

We appreciate your review of this product. Please login to your account to leave a review.