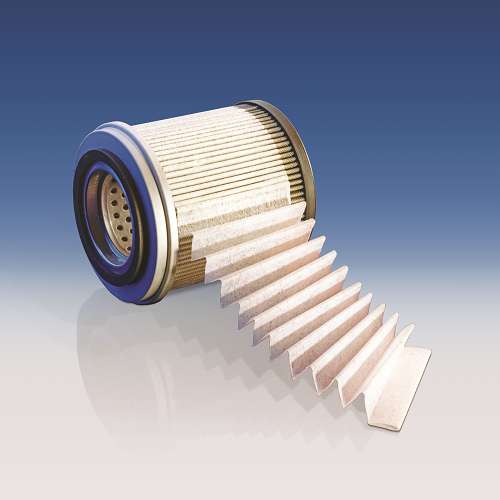

Fuel, Lube, Hydraulic Inline and Liquid Coolant Filter Elements for Aerospace that are optimised to provide the best filter performance in terms of

- Low Weight and Small Space Envelope

- Long Filter Element Service Life

- High Reliability

- Stable Performance

They are also

- OEM approved

- Fuel filter elements compatible with Sustainable Aviation Fuel (SAF)

Control fluid cleanliness and reduce maintenance costs

Maintaining a specified level of fluid cleanliness is critical to the operation and reliability of aerospace fluid systems and equipment. Pall Aerospace filter elements leverage our decades of knowledge and experience. This ensures that the final product is a high-performance, cost-effective filter element.

Learn more about how Pall Aerospace filter elements protect engine fuel and lubrication systems.

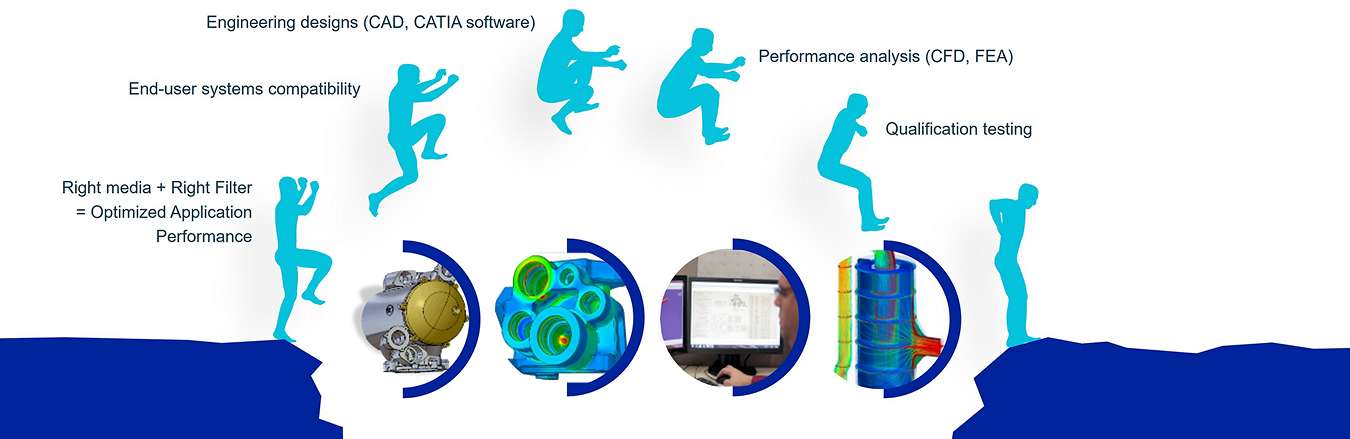

Optimising Filter Performance | Weight | Space | Cost

Designing a filtration system is a complex process that requires significant knowledge and experience. Every filter design is tailored to the specific program. Our design engineering team and technical experts will work side-by-side with you to achieve the optimum performance in the smallest envelope with the lowest weight possible.

How to prevent electro-static charge in aircraft fluid systems

Triboelectric charge generation results from frictional contact between the fluid and surfaces of various materials in the fluid system, including the fibrous media in filter elements. In the absence of mechanisms to dissipate the charge, it can build-up on the system components such as the filter element.

Excessive charge build-up can lead to

- Arcing and physical damage of fluid system components, including the filter

- Fluid breakdown

- Safety issues

Pall’s patented Electro-Static Discharge (ESD) pin was developed to dissipate this charge from the filter element by providing a conductive path to the filter assembly. It is qualified and installed in fuel systems on a number of engine platforms. e.g. GTF, Passport and LEAP

Why do some engines use a dual stage filter element in their lubrication systems?

A dual stage engine lubrication filter system facilitates engine ETOPS (Extended Range Twin Engine Operations, now referred to as Extended Range Operations) approval for some OEM engine designs. It combines a primary finer filter element and a secondary coarser filter element (>70 µm) configured in series.

If the primary filter element becomes fully loaded with contaminant and goes into bypass, the fluid still passes through the coarser, secondary filter.

This provides an acceptable level of filtration for a specified period, avoiding engine shut down that would be required by some engine OEMs if the engine lubricant was not filtered. It also provides protection during cold starts when the primary filter element may be in bypass mode.

Platforms include: CH-53K, UH-60, S92, PW4000 and GTF

Pall’s filter elements provide fluid system protection for a wide variety of liquid system applications including:

- Engine Lube Systems

- Engine Fuel Systems

- Hydraulic Systems

- Liquid Cooling Systems

- Helicopter Transmission Lube systems

We have been supplying aerospace filter elements since the 1960s when Dr.Pall’s novel Rigimesh stainless steel filters were used to improve the reliability of the B707 hydraulic systems by minimizing the impact of contamination on system operation.

We have decades of experience providing solutions for commercial and military aerospace programmes. Each design is specific to the application, some examples are below.

|

|

|

Literature and Other Resources

Common myths and misunderstandings about filtration

- If the fluid looks clear and does not feel gritty then the fluid is clean enough

- Liquid system filters get finer as they plug up with contaminant

- Fine filtration alone is sufficient to protect aircraft hydraulic systems

- Fluid taken directly from the storage barrel is sufficiently clean

- The absolute filter rating guarantees 100% removal efficiency for particles larger than the specified filter rating

Listen to our webinar on the “5 myths of filtration” to find the answers

SAF (Sustainable Aviation Fuels) Pall Solution Support Document

Our filter elements are designed and tailored to meet the customer specification requirements. We understand aircraft fluid system filtration and can provide advice and recommendations regarding filtration for effective fluid system contamination control. We can provide support in writing the filter element performance specifications.

If you have an aerospace program that needs a liquid filter element, either inline or offline, please talk to one of our experts Contact Aerospace

For commercial aircraft products, please contact our authorised distributor, Satair

We appreciate your review of this product. Please login to your account to leave a review.