39 Results of 39 total products

Datasheets

Download:Small Volume and Scalable

Supracap 50 capsules are designed for developing and optimizing a process during scale-up and scale-down studies. They can be used to quickly and accurately determine which series and grade of depth filter media will provide the best performance as well as the necessary filtration area required to meet process volume.

Supracap 50 capsules are readily scalable to Pall Supracap 100 capsules, Supradisc™ I, and Supradisc II depth filter modules. Supracap 50 capsules are also available with Seitz® HP sheet media (double-layer) that scales to Pall Supradisc HP filter modules. Supracap 50 capsules are available with a wide selection of Seitz depth filter media for optimal grade selection.

High Quality Standards

- Batch tested in order to meet all quality requirements

- Manufactured under a Quality Management System certified to ISO 9000

- All plastic components used in construction meet the specifications for Biological Reactivity Tests in vivo for Class VI Plastics (121 °C) as described in the current United States Pharmacopoeia (USP).

Fields of Application

|

|

Pall UpScaleSM Program

From drug discovery and basic research, through process development and production, Pall Corporation is the single source for all your filtration and separation needs. Our UpScale program provides you with the scalable products and support you need to bring new products to market faster.

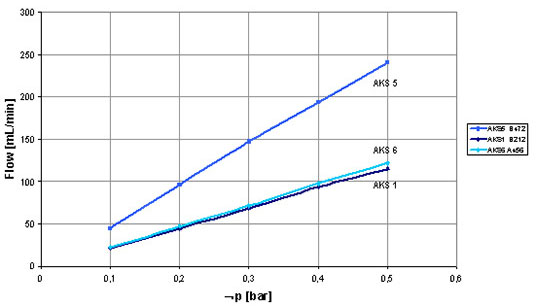

Pall Activated Carbon Filters

Supracap 50 capsules are also available as part of the scalable Pall activated carbon filter range, incorporating Seitz® AKS filter media in 9 different grades of carbon.

Further Information

Further information is available on Pall's range of Filter Modules and Capsules with Seitz Depth Filter Media and also the Pall Supracap Depth Filter Capsules range of products.

Typical1 Values for Ions after Flushing with 50 L/m2 WFI (Supracap 50 HP with 100 L/m2 WFI)

| Ca | Mg | Fe | Cu | Al | Ni |

| <0.5 ppm | < 0.1 ppm | < 0.1 ppm | < 0.1 ppm | < 50 ppb | < 10 ppb |

1 The tests were carried out according to the methods of the Technical/Analytical Work Group within the European Depth Filter Association, or in accordance with in-house test methods.

Materials of Constructions

| Media | Cellulose base 2 |

| Capsule | Polypropylene |

| Vent | Polypropylene |

| Sealing technology | Thermal bonding |

2 See ordering information

Operating Parameters 3

| Maximum operating pressure and temperature | 3 bar (44 psi) at 40 oC |

| Maximum differential pressure | 1.5 bar (22 psi) |

3 In compatible fluis which do not soften, swell or adversely affect the filter or its materials of construction

Sterilization

| Autoclaving at 125 oC | 1 cycle x 30 minutes |

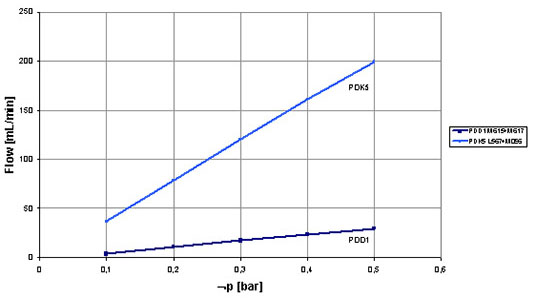

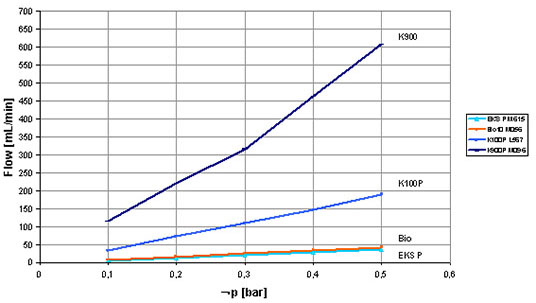

Typical Flow Rates

Flow dp HP series

Technical Specification

| Code4 | Depth Filter Type | Typical Water Permeability in L/min/m2 @ Δp 1 bar (14.5 psid) | Nominal Retention Rating in µm | Ash Content in % | Endotoxin Level in EU/mL before Rinsing |

| PDAX | PDAX | 15 | 0.05 – 0.3 | 60 | < 0.06 |

| PDD1 | PDD1 | 25 | 0.1-0.85 | 52 | <0.06 |

| PDE1 | PDE1 | 27 | 0.1 – 3.0 | 52 | < 0.06 |

| PDE2 | PDE2 | 35 | 0.2-3.5 | 47 | <0.06 |

| PDH4 | PDH4 | 93 | 0.5-15.0 | 45 | <0.06 |

| PDK5 | PDK5 | 151 | 1.5-20.0 | 45 | <0.06 |

| PDK7 | PDK7 | 463 | 3 - 20 | 45 | <0.06 |

| PDP8 | PDP8 | 1010 | 6 - 30 | 39 | <0.06 |

| PDK11 | PDK11 | 173 | 2 - 20 | 49 | <0.06 |

| PEKX | EKXP | 25 | 0.05 – 0.2 | 62 | < 0.06 |

| PEKS | EKSP | 29 | 0.1-0.3 | 58 | <0.06 |

| PEKM | EKMP | 41 | 0.2-0.5 | 48 | <0.06 |

| PEK1 | SUPRA EK1P | 64 | 0.2-0.5 | 47 | <0.06 |

| P050 | KS 50P | 93 | 0.4-0.8 | 46 | <0.06 |

| P080 | SUPRA 80P | 159 | 1.0-3.0 | 49 | <0.06 |

| P100 | K100P | 149 | 1.0-3.0 | 45 | <0.06 |

| P200 | K200P | 217 | 3.0-6.0 | 43 | <0.06 |

| P250 | K250P | 535 | 4.0-9.0 | 44 | <0.06 |

| P700 | K700P | 935 | 6.0-15.0 | 45 | <0.06 |

| P900 | K900P | 1980 | 8.0-20.0 | 45 | <0.06 |

| B010 | BIO 10 | 30 | 0.2-0.4 | <1 | <0.06 |

| B020 | BIO 20 | 75 | 0.4-1.0 | <1 | <0.06 |

| V100 | V100 P | 173 | 2-4 | 53 | <0.06 |

NA - Not Applicable as endotoxin content is not a measured

4 Other grades available on request

Dual-Layer Filter Media Grade Combinations

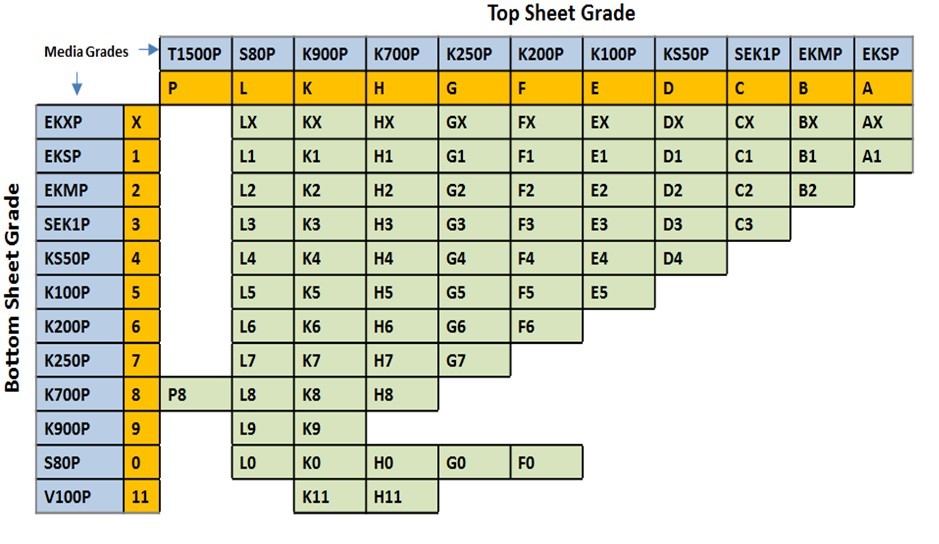

Media Grade Codes for Stax™, Supracap™ and Supradisc™ ModulesA dual layer media grade is a combination of two single layer media grades. The media grade code starts with P (Pharmaceutical Grade) followed by D (Dual layer) and the appropriate dual media combination ID. For generating a dual media combination ID, the appropriate top sheet grade letter (columns) is combined with the bottom sheet grade number or “x” (lines).

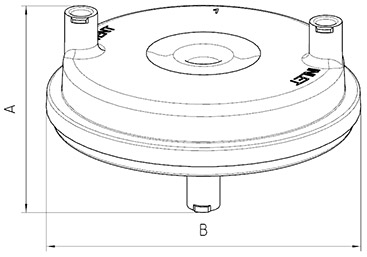

Nominal Dimensions

| A | Supracap 50 single layer Supracap 50 HP |

42 mm (1.65 in.) 52 mm (2.05 in.) |

| B | 64 mm (2.52 in.) | |

Typical Filtration Area

| 22 cm2 (3.41 in.2) |

Connections

| Venting, inlet and outlet | Luer-lock |

Regulatory/Quality Documentation

We appreciate your review of this product. Please login to your account to leave a review.