11 Results of 11 total products

Datasheets

Download:Gamma Compatible, Sterilizing Grade Air Filtration

For single-use installations, from upstream to final formulation and fill, Emflon II membrane is the go-to gas filter for safeguarding cell cultures and drug product from adventitious bacterial and viral contamination.

Mini Kleenpak capsules with Emflon II membrane delivers scalable, gamma-compatible, sterilizing grade air filtration for use on process gas and vent applications. With a comprehensive validation and quality package, Mini Kleenpak capsules with Emflon II membrane are the perfect air filter technology to implement through clinical development to licensed drug manufacture.

Features and Benefits

- Highly-retentive Emflon II membrane for sterility assurance

- High flow-rates associated with low differential pressure enable the use of small filters – reduction of installation and operating costs

- Gamma-irradiatable, autoclavable or available pre-sterilized for maximum convenience

- Integrity testable using the forward flow and bubble point test

- Choice of connection options for enhanced flexibility

Biological Tests

- Meets USP biological reactivity tests in vivo, in accordance with USP class VI plastics at 121°C

High Quality Standards

- Validated in liquids with Brevundimonas diminuta (ATCC 19146) at a challenge level of 107 organisms/cm2 of filter area

- 100 % integrity tested during manufacturing

- Identified by a lot number and unique serial number for complete traceability of manufacturing history and for user traceability systems

- Comprehensive batch/release testing supported with a pharmaceutical certificate of test for each filter

- Validation guide available

- Manufactured under a quality management system certified to ISO 9001:2015

Nominal Dimensions

| KA1 Capsule | KA2 Capsule | KA3 Capsule | |

| Maximum Diameter (Including Valves) | 90.5 mm (3.6 in.) | 90.5 mm (3.6 in.) | 105.5 mm (4.2 in.) |

| Length with Hose Barb Connections | 158 mm (6.2 in.) | 198 mm (7.8 in.) | 210 mm (8.3 in.) |

| Length with Sanitary Connections | 117 mm (4.6 in.) | 157 mm (6.2 in.) | 174 mm (6.8 in.) |

| Nominal Filtration Area | 380 cm2 (0.41 ft2) | 820 cm2 (0.88 ft2) | 1700 cm2 (1.83 ft2) |

Materials of Construction

- Membrane hydrophobic: Hydrophobic PVDF

- Support and drainage layers: Polypropylene

- End cap and core: Polypropylene

- Outer shell: Polypropylene

- Vent and drain valve O-rings: Ethylene propylene (EPDM)

Operating Conditions1

- Maximum temperature: 40 °C

- Maximum operating pressure: 3.5 bar (50 psi) at 40 °C

1 In air/nitrogen gas service or other compatible fluids, which do not soften, swell, or adversely affect the filter or its materials of construction.

Sterilization

- Gamma irradiation maximum dosage (G option only): Up to 50 kGy

- Autoclave sterilization:

- Gamma-irradiated filters: 1 one-hour cycle at 125 ºC for the purpose of post-use decontamination

- Non gamma-irradiated filters: Up to 3 one-hour cycles at 125 ºC

Warning: Kleenpak filters must not be in situ steam-sterilized by passing steam through under pressure. The figures are maximum allowable figures determined by testing under controlled laboratory conditions to the total number of hours indicated. Actual operating conditions may affect the filters long-term response to sterilization. Filters should be qualified for each process application.

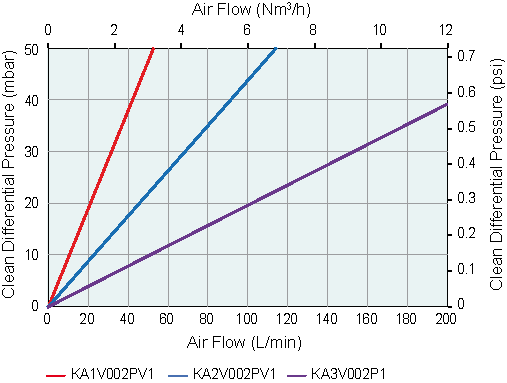

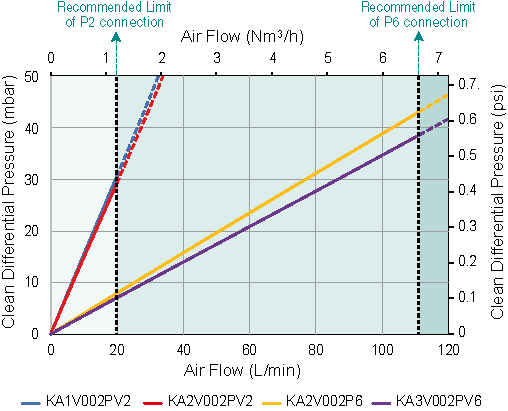

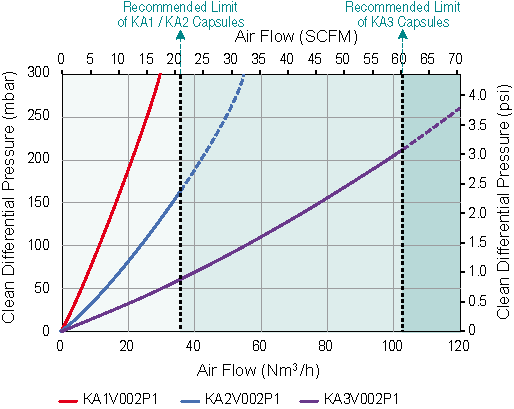

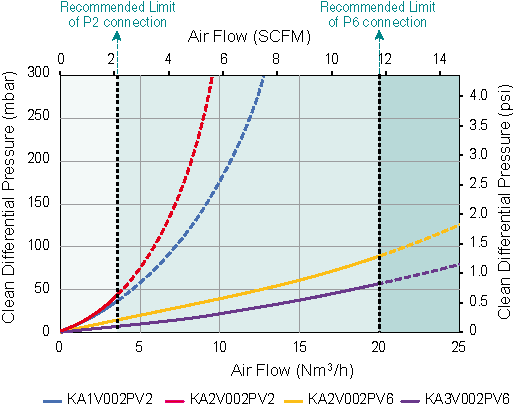

Typical Air Flow Rates2,3

Figure 1Sanitary flange connections: vent conditions

Figure 2

Hosetail connections: vent conditions

Figure 3

Sanitary flange connections: 2 bar operating pressure

Figure 4

Hosetail connections: 2 bar operating pressure

2 For gases other than air or nitrogen, contact your local Pall representative.

3 Recommended flow limits have been based on a maximum velocity of 20 m/s through the capsule. Customer tubing sizes should also be considered.

Regulatory/Quality Documentation

| Description | Part Number |

| KA1V002PV1S | Kleenpak capsule with Emflon II membrane, with 1½ in. sanitary flange, gamma-irradiated |

| KA1V002PV1G | Kleenpak capsule with Emflon II membrane, with 1½ in. sanitary flange, non irradiated |

| KA1V002PV2S | Kleenpak capsule with Emflon II membrane, with ¼ – ½ in. hose barb, gamma-irradiated |

| KA1V002PV2G | Kleenpak capsule with Emflon II membrane, with ¼ – ½ in. hose barb, non irradiated |

| KA2V002PV1S | Kleenpak capsule with Emflon II membrane, with 1½ in. sanitary flange, gamma-irradiated |

| KA2V002PV1G | Kleenpak capsule with Emflon II membrane, with 1½ in. sanitary flange, non irradiated |

| KA2V002PV2S | Kleenpak capsule with Emflon II membrane, with ¼ – ½ in. hose barb, gamma-irradiated |

| KA2V002PV2G | Kleenpak capsule with Emflon II membrane, with ¼ – ½ in. hose barb, non irradiated |

| KA2V002PV6S | Kleenpak capsule with Emflon II membrane, with ½ in. hose barb, gamma-irradiated |

| KA2V002PV6G | Kleenpak capsule with Emflon II membrane, with ½ in. hose barb, non irradiated |

| KA3V002PV1S | Kleenpak capsule with Emflon II membrane, with 1½ in. sanitary flange, gamma-irradiated |

| KA3V002PV1G | Kleenpak capsule with Emflon II membrane, with 1½ in. sanitary flange, non irradiated |

| KA3V002PV6S | Kleenpak capsule with Emflon II membrane, with 1½ in. hose barb, gamma-irradiated |

| KA3V002PV6G | Kleenpak capsule with Emflon II membrane, with 1½ in. hose barb, non irradiated |

We appreciate your review of this product. Please login to your account to leave a review.