21 Results of 21 total products

Datasheets

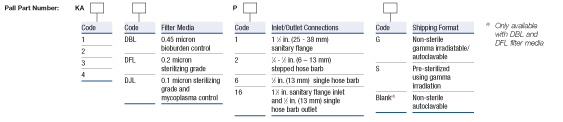

Download:Kleenpak capsules are rugged and compact, can be supplied with a broad range of filter media, and can be offered in up to four different filter area sizes designed for a variety of applications in pharmaceutical manufacturing environments (volumes of 30 L to 1000 L) from small to large-scale. These in-line single-use assemblies are available with sanitary or hose barb inlet/outlet fittings.

Key Features and Benefits

- Encapsulated format for higher flexibility, minimized cleaning and low installation costs

- Built in prefiltration

- Minimal hold up volume

- Low extractables

- High protein transmission

- Rapid preservative recoveries

- Easy integrity testing

- Compatible with organic solvents, acids and chemicals¹

- Resin and surfactant-free

- Melt-sealed, non shedding

¹ Except ketones and amides

Quality Standards

- Manufactured for use in conformance with cGMP

- 100 % integrity tested

- ISO 9000 Certified Quality System

- Meets USP Biological Reactivity Test in vivo for Class VI-121 °C plastics

- Every filter tested during manufacture

- Test correlated to microbial retention

- Certificate of Test provided includes

- Fabrication Integrity

- Bacterial Retention

- Material of Construction

- Effluent quality for cleanliness, TOC and water conductivity, pH and pyrogens

Materials Of Construction

| Filter Membrane | Hydrophilic modified PVDF |

|

Support/Drainage |

Polypropylene Polypropylene Polypropylene |

| Sealing Technology | Thermal bonding without adhesives |

Operating Parameters¹

| Maximum Operating Temperature | 40 °C |

| Maximum Operating Pressure | 5.2 bar (75 psi) at 20 °C 4.0 bar (58 psi) at 40 °C |

| Maximum Differential Pressure (Forward Direction) | 4.0 bar (58 psi) at 40 °C |

Sterilization²

| Autoclave (G and blank option only) | 30 x 60 minutes at 125 °C 10 x 60 minutes at 140 °C |

| Gamma Irradiation (G option only) | Maximum of 50 kGy |

Typical Extractables in Water at 20 °C³

| < 5 mg per capsule |

Nominal Dimensions

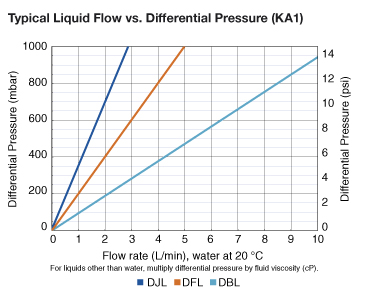

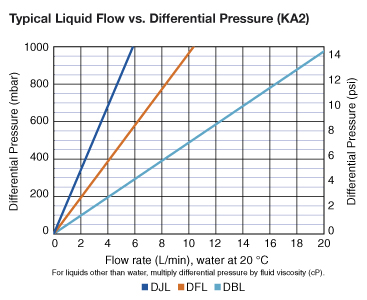

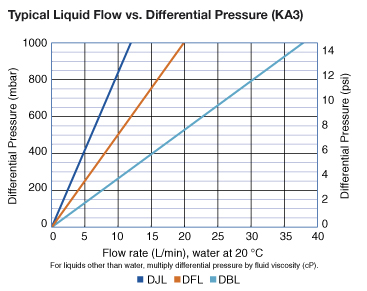

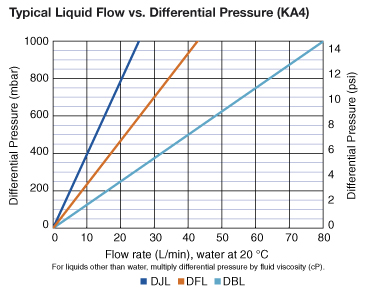

| KA1 | KA2 | KA3 | KA4 | |

| Diameter incl. Valves | 94 mm (3.7 in.) | 94 mm (3.7 in.) | 105 mm (4.1 in.) | 105 mm (4.1 in.) |

| Length - Code 1 | 117 mm (4.6 in.) | 157 mm (6.2 in.) | 174 mm (6.8 in.) | 287 mm (11.3 in.) |

| Length - Code 2 | 158 mm (6.2 in.) | 198 mm (7.8 in.) | - | - |

| Length - Code 6 | 157 mm (6.2 in.) | 197 mm (7.7 in.) | 210 mm (8.3 in.) | 327 mm (12.8 in.) |

| Length - Code 12 | 137 mm (5.4 in.) | 177 mm (7.0 in.) | - | - |

| Length - Code 16 | 137 mm (5.4 in.) | 177 mm (7.0 in.) | 192 mm (7.6 in.) | 305 mm (12.0 in.) |

Nominal Effective Filter Area (EFA)

| KA1 | 400 cm² (0.4 ft²) |

| KA2 | 800 cm² (0.9 ft²) |

| KA3 | 1500 cm² (1.6 ft²) |

| KA4 | 3300 cm² (3.6 ft²) |

Regulatory/Quality Documentation

We appreciate your review of this product. Please login to your account to leave a review.