Datasheets

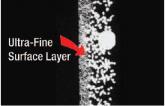

Download:Manufacturing is done completely in-house, including the production of the metal fibers, the formulation of the proprietary base medium, and the design of the element. The process concludes with Pall's scientifically controlled sintering process.

The sintering process fuses the structure of the filter media, insuring a “weld-bond” which utilizes no “binders” that might otherwise shed and contaminate downstream equipment and/or final product quality.

Produced from fine metal fibers ranging from 2 to 38 μm in diameter, the resulting filtration medium exhibits high-efficiency particulate capture and low flow resistance characteristics.

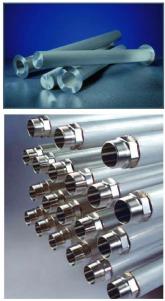

Gaseous service filter cartridge configurations are available in point-of-use designs (i.e. cleaned off-line), or as self-cleaning elements (i.e. blowback filters).

Advantages of Dynalloy Medium:

Resistant in high-temperature and/or corrosive environments- Sintered medium design guarantees a fixed pore structure, resulting in quantitative solids separation and superior effluent quality

- Uniform pore distribution produces a barrier medium that exhibits low flow resistant characteristics and high void volume

- Flame-arresting characteristics provide a high level of safety in handling pyrophoric or explosion-prone powders

| Media Grade | Gaseous Removal Rating1 | Thickness (in.) | Thickness (mm) | Air Permeability2 (psid-ft.2/scfm) | Air Permeability3 (bar[d]-m2/Nm3/hr) |

| XU4 | 1.3 μm | 0.028 | 0.71 | 0.0056 | 2.3 x 105 |

| D215 & D034 | 2.6 μm | 0.023 | 0.58 | 0.0027 | 1.1 x 105 |

| XT28 | 3.3 μm | 0.035 | 0.89 | 0.0023 | 9.2 x 106 |

| XT89 | 10.0 μm | 0.044 | 1.12 | 0.00018 | 7.3 x 107 |

1 The 98% (minimum) removal efficiencies are based on latex bead challenges (in liquid) per ASTM F 662-86. From these results, a liquid-to-gas removal efficiency ratio of 3:1 was determined based on results from field trials.

2 Air permeability determined per ISO 4022. Pressure drop in psi obtained by multiplying value shown by actual gaseous flow rate desired (ACFM) and the ratio of viscosities (actual cP I 0.Q18 cP), all divided by total filtration area (ft.2) of grade selected.

3 "N" (normal) conditions assumed to be 32°F (O °C) and 1.0 atmosphere.

Available Configurations4:

Blowback Elements:Standard Diameters of 2 in. (50.8 mm), 23⁄8 in. (60.3 mm), 31⁄2 in. (88.9 mm), 41⁄2 in. (114.3 mm)

Available in lengths up to 186 in. (4,724.4 mm).

Metal Blowback Bags:

Standard Diameters of 31⁄2 in. (88.9 mm), 41⁄2 in. (114.3 mm)

Available in lengths up to 186 in. (4,724.4 mm).

4 Standard configurations shown. Please consult your Pall representative for other configuration availability.

Uses:

Refinery:FCC TSS & FSS Flue Gas; Catalyst Hopper Vent Gas, etc.

Mineral Processing:

Off-Gas Solids Recovery from Calciners, Incinerators, Fluid Bed Dryers, and Storage Silos

Chemical:

Catalyst Recovery in Fluidized Bed & Slurry Loop Reactors (PP, HDPE, LDPE, Fumed Silica & Polycrystalline Silicon, Maleic Anhydride, etc.)

Alternative Energy:

Biomass & Coal Gasification Flue Gas, Fischer Tropsch Synthesis

Materials of Construction

316/316L SST; 310 SST; Inconel4 600; Hastelloy5 X; Hastelloy5 C-2000; Haynes5 HR-1605

4 Inconel is a registered trademark of Special Metals Corporation.

5 Hastelloy, Haynes, and HR-160 are registered trademarks of Haynes International, Inc.

We appreciate your review of this product. Please login to your account to leave a review.