- Proprietary depth construction with an absolute rated downstream section, and a continuously profiled pore size upstream section

- PPS medium is chemically inert for use in aggressive service

- Tin plated carbon steel cores provide excellent mechanical strength

- Outside to inside flow

- 3.7" (9.4 cm) diameter, 37" (94 cm) long element provides long service life

- Knife-edge seal elements retrofit existing 1401 housings when used with specially designed 1401 housing adapter

Features and Benefits:

The depth style Profile A/S 1401 Series PPS filter element offers the following benefits versus commonly utilized pleated paper 1401 style filters.| Feature | Advantage | Customer Benefit |

|---|---|---|

| No potting agents utilized | No potting agents used to attach filter end caps as is done with 1401 style pleated paper elements | Wider temperature and chemical compatibility |

| Depth style media | Greater ability to remove soft deformable contaminants | Enhanced fluid quality |

| Fine fibers utilized | Medium void volume >80% vs <50% for paper medium | Long filter life |

Performance Specifications

Filter Grades:

| Liquid: | 60 micron |

| Gas: | 10 micron1 |

Maximum Temperature Rating:

30 psid (2.0 bard) @ 400°F (205°C)

40 psid (2.8 bard) @ 200°F (93°C)

Maximum Operating Temperature:

400°F (205°C) in most fluids excluding strong acids and bases2.

Soak test in process fluid recommended for all temperatures

in excess of 250°F (121°C).

Product Specifications

Materials of Construction

| Filter media: | Polyphenylene Sulfide (PPS) |

| Center core: | Tin plated carbon steel |

Dimensions (nominal):

| Outside diameter: | 3.7" (9.4 cm) |

| Inside diameter: | 2.25" (5.7 cm) |

| Length: | 36.8" (93.5 cm) |

Filter Media Characteristics:

The fibers in Profile A/S 1401 Series filters are continuous for

practical purposes.

Surfactants, Binders:

No binder resin or surfactants are used in the manufacture of

these filters. Fibers are “bonded” by intertwining during the

manufacturing process.

Toxicity:

The filter media meets the specifications for biological tests

listed in the current revision of USP for Class VI plastics at 121°C

1 Gas rating translated from determined liquid rating based on experience.

2 Users should check compatibility of specific process fluids prior to use.

Particle Retention

Cartridge Designation | Removal Rating Liquid Service Micron at 99.9% Efficiency3 Beta 1000 99.9% | Typical Clean Pressure Drop Aqueous Service4 PSI/GPM |

Typical Clean MBAR/LPM |

|---|---|---|---|

| R1401FPS600 | 60 | .0016 | .0289 |

3 Ratings determined using oil F2 Test (ISO Coarse Test Dust in MIL-H-5606; single pass mode).

4 Pressure drop in PSI per GPM water for a single element. Multiply this value by the required flow to determine the total aqueous pressure drop. Next, for fluids other than water, multiply by viscosity in centipoise. If this calculated pressure drop is excessive, then divide this value by the number of filters required to reduce this pressure drop to an acceptable level.

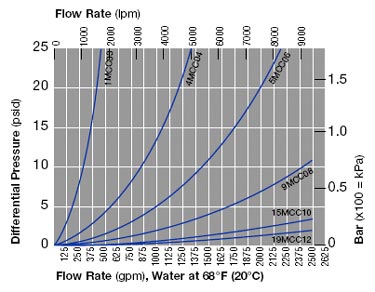

MCC1401 Housings - Aqueous Pressure Drop

To calculate the actual housing pressure drop, multiply this aqueous pressure drop by the fluid’s specific gravity. This value must be added to the filter pressure drop to calculate the overall pressure drop of the filter system.

Housing Information

A full line of standard and custom Pall MCC1401 housings, designed and built to the ASME code, are available. Refer to Table 2 for more information.

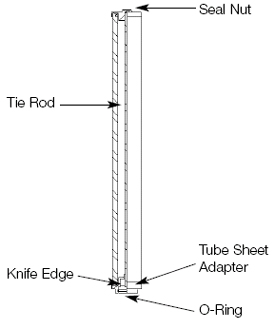

A Pall supplied retrofit tie rod assembly is required to utilize Profile A/S 1401 style elements in existing 1401 style housings. This assembly allows for use of a knife edge seal style element in a housing that normally accepts end capped filters with internal O-rings.

The retrofit assembly consists of a top and bottom seat cup and tie rod. The bottom O-ring to knife-edge seal cup is placed over the housing riser pipe. The Profile A/S 1401 Series element is placed over each tie rod. The elements are sealed in place by screwing the top metal seal nut onto the top of the tie rod. When fully engaged, the tie rod/seal nut assembly forms a knife-edge sealing surface at both the top and bottom of the element.

Table 2. Standard MCC1401 Housings - Carbon Steel, Rated 285 psig/19.6 bar, and 100°F/37°C

| Part Number | Number of Filters | Nominal Vessel Diameter in/mm | Inlet/Outlet Flange Size in/mm | Housing Height in/mm |

Housing | Housing Weight (full) lb/kg |

|---|---|---|---|---|---|---|

| 1MCC0603F1285 | 1 | 6.625/168.3 | 3/76.2 | 54.25/1378 | 200/91 | 250/113 |

| 4MCC1004F1285 | 4 | 10.75/273.1 | 4/101.6 | 59/1498.6 | 440/199 | 585/265 |

| 5MCC1206F1285 | 5 | 12.75/323.9 | 6/152.4 | 64/1625.6 | 680/308 | 925/419 |

| 9MCC1608F1285 | 9 | 16/406 | 8/203.2 | 84/2133.6 | 1070/485 | 1570/712 |

| 15MCC2010F1285 | 15 | 20/508 | 10/254 | 93/2362.2 | 2000/907 | 2750/1247 |

| 19MCC2412F1285 | 19 | 24/609.6 | 12/304.8 | 110/2794 | 2300/1043 | 3500/1587 |

Retrofit Tie Rod Assembly

We appreciate your review of this product. Please login to your account to leave a review.