Datasheets

Download:High Capacity Pleated Filter Cartridges With Microfiberglass Media

- Unique media of microfiberglass filter cartridges provides exceptional dirt-holding capacity for longer service life

- 304 stainless steel center core and end caps available for high temperature applications

- Small diameter fibers ensure high flow rates at low pressure drops

- Economical alternative to stringwound cartridges

- Available in retention ratings of 0.2 to 50 microns (μm)

- Protective netting is color-coded for easy identification of micron ratings

- End configurations to fit most housings

- Core material options for different temperature compatibility

Materials of construction

| Filter media: | |

| 50 μm: | Spunbonded polyester |

| All other grades: | Borosilicate microfiberglass with acrylic binder |

| Support material: | Spunbonded polyester |

| Netting: | Polypropylene |

| Hardware: | Polypropylene or 304 stainless steel1 |

| Sealing: | Thermal bond |

| Gaskets/O-rings: | Silicone elastomer, nitrile, fluorocarbon elastomer, hydrocarbon rubber, FEP encapsulated silicone, expanded PTFE, white nitrile, white silicone |

Dimensions (nominal)

| Outside | Diameter: 6.6 cm (2.6 in) |

| Lengths: | 10.2 cm (4 in), 24.8 cm (9.75 in), 25.4 cm (10 in), 49.5 cm (19.5 in), 50.8 cm (20 in), 74.3 cm (29.25 in), 76.2 cm (30 in), 99.1 cm (39 in), 101.6 cm (40 in) |

1304 stainless steel end caps are epoxy bonded.

Performance Specifications

Filter grades

0.2, 0.45, 1, 3, 10, 30, 50 μm

Recommended change-out differential pressure1

2.4 bard (35 psid)

Maximum differential pressure

Polypropylene hardware

4.8 bard (70 psid) @ 20°C (68°F)

2.8 bard (40 psid) @ 65˚C (150˚F)

304 stainless steel hardware

5.2 bard (75 psid) @ 121°C (250°F)

Color Code Chart For Duo-Fine E Series

| Netting Color | Micron Rating |

| Yellow | 0.45 |

| White | 1 |

| Blue | 3 |

| Red | 10 |

| Purple | 30 |

| Orange | 50 |

Particle Retention (μm)

| Liquid Service (by ASTM F-795 Test) | Gas Service | ||

| Cartridge 90% >99.9% Removal Designation |

90% Efficiency | >99.9% Efficiency | Removal Efficiency by DOP Test |

| DFN 0.2 | 0.2 | 1.0 | 99.999% |

| DFN 0.45 | 0.45 | 2.0 | 99.998% |

| DFN 1 | 1.0 | 4.0 | 96% |

| DFN 3 | 3.0 | 10.0 | ---------- |

| DFN 10 | 10.0 | 18.0 | ---------- |

| DFN 30 | 30.0 | 45.0 | ---------- |

| DFN 50 | 50.0 | 75.0 | ---------- |

Duo-Fine E Series filter cartridges have been extensively laboratory and field tested to determine removal efficiencies in the most stringent of operating conditions.

The removal rating of any filtration device will depend on, to some extent, the conditions under which it is used or tested. The test results will be influenced by the nature of the fluid, its viscosity, the flow rate, the type of contaminant, and the temperature.

The ratings given represent the diameter of the largest hard spherical particle that will pass through the filter during standard test. Contact Pall for a complete description of Pall's test procedures.

The DOP test measures the ability of the filter to capture fine droplets in air or gas. The retention ratings given represent the removal efficiencies with respect to an aerosol dispersion of 0.3 μm Dioctyl Phthalate (DOP) particles.

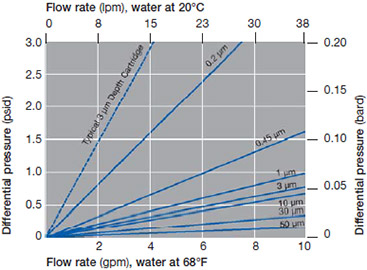

Typical Flow vs. Differential Pressure for Application Sizing

Unit conversion: 1 bar = 100 kPa

Flow rate is for a 25.4 cm (10 in)cartridge. For liquids other than water, multiply differential pressure by fluid viscosity (cP).

1Provided that the maximum differential pressure is not exceeded based on temperature limits defined above.

Pall Part Number = DFN [1] - [2] [3] [4] - [5] [6] [7]

Table 1

| Code | Filter grades (μm) |

| 0.2 | 0.2 |

| 0.45 | 0.45 |

| 1 | 1 |

| 3 | 3 |

| 10 | 10 |

| 30 | 30 |

| 50 | 50 |

Table 2

| Code | Cartridge lengths (cm / in) nominal |

| 4 | 10.2 /4 |

| 9.75 | 24.8 /9.75 |

| 10 | 25.4 /10 |

| 19.5 | 49.5 /19.5 |

| 20 | 50.8 /20 |

| 29.25 | 74.3 /29.25 |

| 30 | 76.2 /30 |

| 39 | 99.1/ 39 |

| 40 | 101.6/40 |

Table 3

| Code | Core materials |

| U | Polypropylene |

| A | 304 stainless steel |

Table 4

| Code | Gasket/O-ring materials |

| S | Silicone |

| N | Nitrile |

| E | Hydrocarbon rubber |

| V | Fluorocarbon elastomer |

| T | FEP encapsulated silicone (O-rings) |

| M | White silicone |

| W | White nitrile (gaskets) |

| X | No O-ring required (M2 style only) |

| T | Expanded PTFE (gaskets) |

Table 5

| Code | End configurations |

| Blank | DOE with elastomer gasket seals & end caps |

| 1X | DOE, 2.54 cm (1 in) extended core |

| M2 | SOE flat closed end, fits housings with 020 O-ring post (polypropylene hardware only) |

| M3 | SOE flat closed end, external 222 O-rings (retrofits other manufacturers’ Code 0) 3 (polypropylene hardware only) |

| M5 | DOE internal 120 O-rings (retrofits 213 O-ring style)3 (polypropylene hardware only) |

| M6 | SOE flat closed end, external 226 O-rings (retrofits other manufacturers’ Code 6)3 (polypropylene hardware only) |

| M7 | SOE fin end, external 226 O-rings (retrofits other manufacturers’ Code 7)3 (polypropylene hardware only) |

| M8 | SOE fin end, external 222 O-rings (retrofits other manufacturers’ Code 5)3 (polypropylene hardware only) |

| M10 | DOE internal O-rings (fits other manufacturers’ housings)3 (polypropylene hardware only) |

| M11 | SOE flat closed end, internal 120 O-ring (retrofits other manufacturers’ X style)3 (polypropylene hardware only) |

Table 6

| Code | Bubble test option |

| Blank | Sample bubble tested |

| B | 100% bubble test |

Table 7

| Code | Packaging |

| Blank | Standard packaging |

| -BLK | Bulk packaging3 |

3For details, contact Pall Corporation.

We appreciate your review of this product. Please login to your account to leave a review.