Datasheets

Download:Pleated Depth Filter Designed Specifically

for Particle Trap Filtration in Beer

This Pall Profile Star TF filter has been designed specifically for use as a particle trap filter to remove filter aid particles from bright beer. The filter utilizes the proven and successful Pall technique of varying the fiber diameter to produce a pore size gradient from coarse (upstream) to fine (downstream), while maintaining a high open area throughout the depth of the filter medium. This proprietary construction has been optimized to deliver the benefits of both traditional pleated and depth style trap filters - the ideal combination. Features and Benefits

- Construction optimized for consistent performance under variation in flow or ΔP increase

- Filter medium designed to prevent fiber migration into the filtered beer

- Very high contaminant holding capacity

- Designed for reverse flow cleaning to optimize filter service life

- All polypropylene construction

- No surfactants or binder resins used in manufacture

- Consistent and verifiable filtration performance

- Long service life, low filtration costs

- High flow rates

- Excellent resistance to typical brewery use chemicals

- Continuous construction without side seam for durability and security of use

- Extra security provided by bayonette lock and double o-ring seal

- All materials meet the requirements for biological safety tests per USP for class VI

plastic at 121 ºC

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Profile Star TF Filters Declaration of Compliance

Materials of Construction

- Filter Media: Polypropylene

- Core and Cage: Polypropylene

- Endcaps: Polypropylene

- O-rings: Ethylene Propylene Rubber

Operating Temperatures and Pressures

| Maximum Operating Temperature* | Maximum Differential Pressure |

| 80 ºC (176 ºF) | 3.4 bar |

| 50 ºC (122 ºF) | 5.0 bar |

*In fluids which do not soften, swell or adversely affect the filter or materials of construction.

Maximum Steam Sterilising Temperature

- 125 ºC (257 ºF)

Maximum Recommended Steam Life

- 10 hours

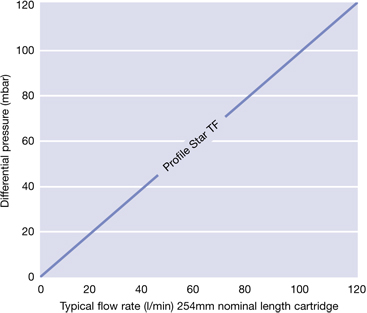

Liquid Flow vs. Differential Pressure

Note: Differential pressures are for liquids with a viscosity of 1 centipoise (cP). For cartridges of 508 mm, 762 mm, 1016 mm nominal length, divide the differential pressure by 2, 3 and 4 respectively. To obtain the total pressure drop of a complete filter assembly the housing pressure drop must be added. Please refer to the relevant housing literature or contact Pall.

Recommended flow rate for sizing 12 hl/hr per 10 in. module

Note: Differential pressures are for liquids with a viscosity of 1 centipoise (cP). For cartridges of 508 mm, 762 mm, 1016 mm nominal length, divide the differential pressure by 2, 3 and 4 respectively. To obtain the total pressure drop of a complete filter assembly the housing pressure drop must be added. Please refer to the relevant housing literature or contact Pall.

Recommended flow rate for sizing 12 hl/hr per 10 in. module

Filter Cartridges

This information is a guide to the part number structure and possible options.

Example Part Number: AB 4 TF 7 W J(See bold references below.)

Part Number: AB <Length Code from Table 1 > TF < 7 (Adaptor Style) > W < J (Material Seal) >

Table 1 - Nominal Length

| Code | Nominal Length |

| 1 | 254 mm |

| 2 | 508 mm |

| 3 | 762 mm |

| 4 | 1016 mm |

Adaptor Style (7)

Bayonet lock with double O-ring sealSeal Material (J)

Ethylene Polypropylene RubberWe appreciate your review of this product. Please login to your account to leave a review.