Brochure

Download:TFF Systems for Yeast Management

The increasing cost of raw materials and energy areforcing the brewing industry to investigate new opportunities for increasing extract yield without compromising quality. Excess yeast contains a significant amount of extract that can be recovered by concentrating the yeast with modern crossflow technology. By combining this technology with controlled diafiltration, the yield can even be boosted. The recovered beer can be blended with the original beer up to a level of 5% volume without negatively influencing the taste. Thus, beer recovery makes a significant contribution to the cost savings of the brewery.Benefits

- Cost reduction can include:

- Very short return on investment (ROI) of about 1 year

- Net revenue > 90% of the invested capital per year

- High mechanical, thermal and chemical resistance of membranes for longer module lifetime

- Easy installation due to modular concept

- High system availability

- Dry matter up to 20% for high yield

- Low maintenance cost

- Low operating expense (OPEX)

- High-quality yeast for sale.

- Excellent beer quality:

- Minimal difference between original beer and blended beer in terms of sensory and analytics

- Closed system for minimum oxygen uptake

- Clear cut off with low turbidity and almost yeast-free beer

- High microbiological safety due to easy cleaning and sterilization with hot water up to

90 °C (194 °F) - Easy to extend due to modular concept

- High yield, long module lifetime, consistent beer quality and reduced energy consumption due to controlled process.

Filter Media

Membralox® Ceramic Membranes

- High flux

- Proven long operational life

- Excellent resistance to corrosion

- Wide chemical and pH (0 - 14) compatibility

- Excellent thermal stability

- Can be sanitized and sterilized

Membralox Modules

- High performance housing design and sealing assembly

- Membralox SD and HCB modules

Analytical Results and Taste Panel Data

To evaluate the percentage of beer which can be blended back to production without compromising the beer quality, several test were conducted. By chemical and sensory analysis carried out by independent institutes, it was shown that a back blending ratio of up to 5 % volume is suitable. The superior quality of the recovered and blended beers has been confirmed as follows:- No identification of blended beers by taste panel

- Minimum deviation (within analytical method sensitivity) by basic analytics

- No significant differences on esters

- No significant differences on short chain fatty acids

- No significant difference in stale flavor active substances

Commercial Aspects

The short ROI with a range between 1 - 2 years make this technology and the investment made into it very attractive to the brewing industry.Example

| Brewery A | Brewery B | |

| Beer output (12° Plato)* | 4,000,000 hl/a | 2,000,000 hl/a |

| Brew house output (16° Plato)* | 3,000,000 hl/a | 1,500,000 hl/a |

| Yeast amount (16° Plato, 3% of brew house output)* | 90,000 hl/a | 45,000 hl/a |

| Recovered beer (~ 80 % yield; 10.5° Plato) | 110,000 hl/a | 50,000 hl/a |

| Beer production cost (at 10 €hl)* | 1,100,000 € | 500,000 € |

| Investment for system* | 500,000 € | 400,000 € |

| Investment for periphery* | 500,000 € | 500,000 € |

| OPEX* / hl | 0.33 € | 0.40 € |

| OPEX / annum | 36,300 € | 20,000 € |

| Costs (CAPEX + OPEX) | 1,036,300 € | 920,000 € |

| Gain / annum | 1,100,000 € | 500,000 € |

|

Return on investment 1 - 2 years |

||

*Estimation

Technical data

| Keraflux-TFF System | ||||||||

| Module lines x modules high | 2 x 2 SD | 2 x 3 SD | 2 x 2 HCB | 2 x 3 HCB | 3 x 2 HCB | 3 x 3 HCB | 3 x 4 HCB | |

| Brewery size1 [hl/a] | 2000,000 | 3300,000 | 3300,000 | 4800,000 | 4800,000 | 7300,000 | 9700,000 | |

| Yeast amount2 [hl/day] | 190 | 310 | 310 | 460 | 460 | 700 | 930 | |

| Footprint filtration unit [m] | Length | 4.50 | 4.50 | 4.50 | 4.50 | 5.50 | 5.50 | 5.50 |

| Width | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | |

| Height | 4.50 | 5.50 | 4.50 | 5.50 | 4.50 | 5.50 | 6.70 | |

| Footprint service unit [m] | Length | 2.55 | 2.55 | 2.55 | 2.55 | 2.55 | 2.55 | 2.55 |

| Width | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | 2.25 | |

| Height | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | 2.00 | |

112° Plato

2Yeast amount: 3% of beer volume (12 ° Plato)

15° Plato

250 working days per year

21 h filtration per day

Diafiltration Principle

In this special process developed by Pall, water is added to the yeast suspension to increase the extract and alcohol recovery (wash out effect) without compromising the beer quality.Cost Reduction by Process Control

The process for yeast extract recovery uses a ceramic cross flow technology with specific control features to achieve reduced costs.- Cost savings

- low consumption of cleaning agents and water

- high system availability and production time

- Long production cycles and less cleaning cycles

- Control of feed flow

- Control of cross flow velocity

- Control of permeate flow and trans membrane pressure (TMP) at each module level against target set points

Process Description

The beer recovery is conducted in a batch process, which offers several advantages:- Improved performance (up to 20%) and quality due to lower yeast concentration in system during batch cycle

- Reduced energy consumption (up to 25%) due to lower yeast concentration in system during batch cycle

- Yield up to 80% due to diafiltration

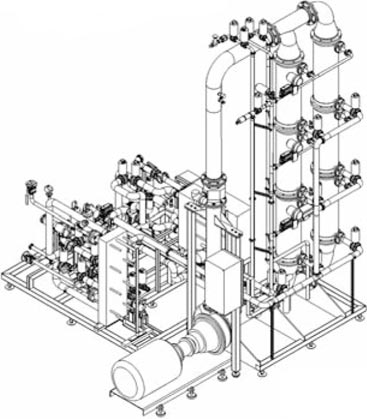

Keraflux-TFF System 2 x 3

TFF Systems

Tangential Flow Filtration

We appreciate your review of this product. Please login to your account to leave a review.