PROFi Membrane Beer Clarification System for DE-free Beer

Datasheets

Download:Changing requirements in the brewing industry have encouraged brewers to rethink their production technologies. Environmental aspects, consumer protection, water shortages, variations in raw material quality, labor costs or an increasing sort-variety are all factors influencing future decisions into new installations.

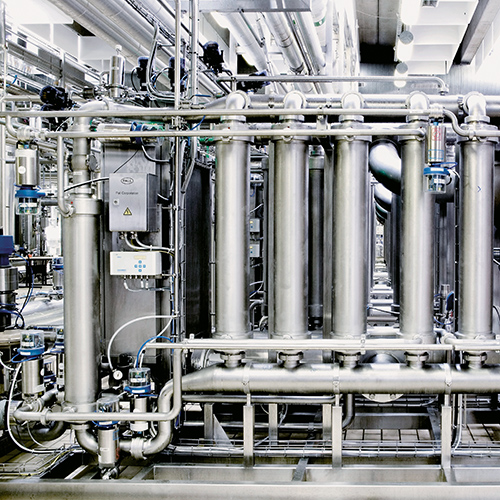

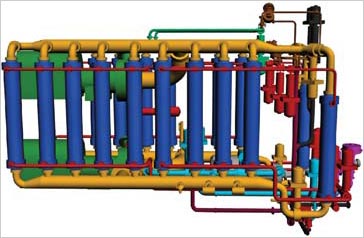

The PROFi membrane system is a modern beer clarification solution that minimizes waste, water and utility consumption while increasing brewery production efficiency. Designed for automated, continuous operation, PROFi membrane systems deliver speed and flexibility of brand changes with bright beer quality and high yield. The modular block design maximizes product security, cleaning effectiveness and utility usage.

The PROFi system combines a high performance centrifuge with a “zero retentate” crossflow membrane filter unit to provide efficient, DE-free clarification of beer. PROFi system technology is a co-operation between Pall Food and Beverage and GEA Westfalia Separator GmbH. It is the engineered result of significant Research and Development built on the extensive and unique brewing experience of the two companies.

The PROFi system technology offers a smart solution to the demands of the brewing industry offering complete DE-free clarification with direct value to the brewery.

The Impact of IoT on Performance and Consumption in Filtration

The implementation of IoT in the beer-making process supports transforming the industry towards sustainable and cost-effective production. With IoT based digitalization in filtration and stabilization , breweries can optimize processes, automate machine learning, and manage data for reporting, traceability, and analysis.

But IoT users have one primary concern in common – data security. Pall values data security as the highest priority and proactively takes all the necessary steps to remain best-in-class. Therefore, it is essential that the latest state-of-the-art technology protects brewery data with penetration tests and code scanning exercises to continuously identify risks and takes the necessary actions to ensure brewery data remains where it is needed.

Data Handling in the Brewery

A modern automated brewery generates and processes a large amount of data during operation. Process control is the primary use of a large portion of this data. A small amount of this goes toward process analysis and optimization.

Pall values data security as the highest priority and proactively takes all the necessary steps to remain best in class. Our goal is to provide an easy means of obtaining quantifiable data for brewing operations. Through Pall BeerIoT, brewers can optimize their operations, improve sustainability and quality initiatives, and improve their OpEx.

PROFi IoT

To gain maximum advantage from the data generated by a PROFi control system Pall implemented IoT-based real-time data management with constant access to valuable information across the organization in user-defined formats. The ability to benchmark against other installations within a brewery group and against the industry average is also available.

Typical examples of digital data analytics are:

- Specific consumption data: water, cleaning agents, electricity, membranes

- Performance data: degree of utilization, efficiency, and downtimes

- Quality data: oxygen uptake, color, original extract, and haze

- Notifications, alarms, and messages

Documentation and service data

Pall IoT provides direct online availability of all system-specific documentation and training documents, spare parts lists, service reports, operating instructions, safety instructions and acceptance reports.

PROFi System Process

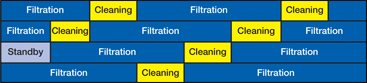

Stabilized beer from fermentation / maturation is pre-clarified with a high efficiency centrifuge, which ensures gentle treatment of colloids and minimal oxygen pick-up. Bulk yeast is separated from the beer and discharged with a high percentage of dry solids. This membrane pre-clarification delivers longer filtration cycles and enhanced system economics. Fine filtration of beer in the membrane unit is continuous, due to membrane blocks alternating in filtration and regeneration. This design ensures constant filter availability and smaller system sizing, reducing both capital and operating expenses. Forward flow module emptying with CO2 enables a fast product change and flexibility without pre or post run blending / loss. Beer protein stabilization may be performed upstream of the centrifuge with silica gel, while polyphenol stabilization is accomplished either upstream of the centrifuge with one way Polyvinylpolypyrrolidone (PVPP) or downstream of the membrane unit with regenerative PVPP or other methods. Ideally the PROFi system is combined with a stabilization system which also runs in a continuous mode.PROFi Membrane System Continuous Operation Blocks

PROFi Membrane System Block Design

Filter Media

At the heart of the PROFi membrane system are the highly engineered membrane module inserts which cover the hollow fiber membranes. The membranes consist of polyethersulfone (PES), which is a reliable, inert material widely applied to beer filtration. The membranes, in combination with the module design, guarantee high mechanical strength resulting in a long service life and optimized costs. The module design includes:- High porosity membrane with highest loading capacity for beer colloids

- Module insert designed for stainless steel housing enabling sanitization up to 74 °C (165 °F) and pressures up to 6 bar (87 psi)

- Fast module exchange

- High mechanical, thermal and chemical resistance

- Reliable yeast reduction

- Reproducible in-situ Module Functioning Tests

Commercial

A PROFi membrane system is an investment into cost effective beer clarification, sustainable technology and brewery production flexibility. The cost saving potential depends on the brewery specific situation and has to be calculated case by case.PROFi Batch System

In order to make DE-free membrane technology accessible for breweries with a lower annual production capacity on an economically attractive basis, the PROFi Batch System was developed. The aim was to use the existing and proven PROFi system technology and design with minor modifications to the installation and process. The PROFi batch system fulfils the technological and economic requirements of breweries with an annual production capacity between 400,000 hl and 1,300,000 hl. The main difference between the standard PROFi system and the PROFi Batch system is the batch-wise operation mode. Filtration and regeneration take place one after another for the complete PROFi system. All the added benefits customers achieve by using the PROFi technology remain unaffected.PROFi Membrane System - Batch Operation

The system consists of 1 or 2 module blocks with 20 or 28 modules, depending on the required total flow rate.

The system consists of 1 or 2 module blocks with 20 or 28 modules, depending on the required total flow rate.

PROFi Batch System - Range

| Flow rate [hl/h] | MBL | Max. volume / day [hl]* | Max. volume / year [hl]* |

| 120 | 1 x 20 | 1,920 | 480,000 |

| 160 | 1 x 28 | 2,560 | 640,000 |

| 240 | 2 x 20 | 3,840 | 960,000 |

| 320 | 2 x 28 | 5,120 | 1,280,000 |

* Filterability 200 l/m², 4 cycles / day, 250 days / year

Benefits*

Cost Reduction

- No use of filter aids like DE

- No purchasing, quality assurance, storage, preparation, health and safety risk management or disposables

- Reduced beer losses

- Solids discharge with high % of dry matter

- Single pass process without any beer retentates after batch end or brand changes

- Special membrane block design reduces dead volume

- Empty modules by forward flow using CO2

- Reduced energy consumption

- “Zero retentate” crossflow filtration with minimum energy input

- Low crossflow velocity

- No internal cooling

- Reduced water and chemical consumption for cleaning

- Low hold-up volume in membrane blocks

- Intelligent cleaning liquor management in terms of media re-use

- Environmental friendly cleaning

- No use of chlorine

- Only simple technical grade chemicals

- High production safety

- Cluster technology allows Module Functioning Test (MFT) and enable ongoing production availability

- Reduced labor costs due to full automation

- Reduced CAPEX

- No need for internal cooling or retentate tank due to single pass crossflow filtration

- Eliminates need for additional particle or fine filtration

- Continuous operation resulting in smaller system and footprint (standard PROFi system)

- Flexible operation resulting in less bright beer tank (BBT) capacity required

- No pre and post runs even when changing from dark beers to light beers

- Reduced OPEX

- Continuous filtration (standard PROFi system)

- Stable filtration cycles nearly independent of incoming beer, yeast and particle load

- 24/7 operation (standard PROFi system)

- Very flexible on different brand changes and whatever the beer stabilization method used

- Low energy, water and chemical demand

- Low waste stream

- Higher system availability

- Fully automated, 24/7 operation

- Clearly defined filtration and cleaning cycle times

- Forward flow module emptying

- No additional handling of pre and post runs

- Cluster technology

Excellent Beer Quality

- Low crossflow velocity with reduced shear forces

- High clarification efficiency of centrifuge and membrane system

- Negligible oxygen pick-up from process

- No differences in analytics and sensory to traditional filtration methods

Microbiological safety due to MFT

- Modules can be tested in-situ before production and removed from service if any defect detected

Sustainability

- No filter aids to dispose

- Reduced water consumption and waste stream

- Reduced chemical consumption

- No use of chlorine and only simple technical grade chemicals used for cleaning

- Low energy consumption

- Low CO2 footprint

- Low water footprint

Consumer Protection

- Best product traceability

- High process safety

- In-situ module functioning test

- Fully automated system

Flexibility

- Low investment costs for increased capacity due to modular design

- Fast product / brand change due to forward flow module emptying

*Benchmarked against traditional DE pre-coat filtration

We appreciate your review of this product. Please login to your account to leave a review.