1/EA

1

Datasheets

Download:SUPRApak L Series-SA filtration units are turn-key systems designed for use with SUPRApak L filter modules. They revolutionize depth filtration applications in the food and beverage industry, providing a cost-effective alternative to classical sheet filtration.

SUPRApak L filtration units provide a closed system approach to high capacity depth filtration, maximizing product protection and minimizing product losses. Lower cost of ownership is achieved due to higher throughput, yield improvement, and reduced handling, cleaning, maintenance and downtime costs, when compared to sheet filtration.

SUPRApak L technology is ideal for use in distilled spirits, beer, sweetener, enzyme, gelatin, yeast extract, and other food and beverage applications.

SUPRApak L Series-SA units provide a complete installation package including standard accessories, which allows quick integration into an existing system. They hold from one to six SUPRApak L modules, representing up to approximately 60 m2 (646 ft2) of filtration area in a very compact and low hold-up volume design. They are available either in single dome or flexible modular design.

| Features | Benefits |

| Closed filtration system | • Increased process safety and product quality; minimized product losses, product contamination risk and personnel exposure to process fluids |

| Installation package with standard accessories | • Turn-key installation allows quick integration into existing system |

| Compact design with high filtration area | • Extremely high throughput at low investment cost |

| Drainable, low hold-up volume assembly | • Higher product yield; minimized cleaning costs |

| High quality internal surface finish, sanitary and crevice-free design | • Enhanced cleanability |

| Flexible modular design | • Production volumes can be matched to equipment capacity; capability for future expansion |

| External tensioning device with preset torque limit | • Provides secure operation without bypass |

| Dual inlet connections on sizes exceeding 3 modules | • Minimizes product mixing zones |

| Simple, quick installation and servicing | • Reduced labor, maintenance and downtime costs |

| Filter module lifting device available on request | • Eases filter installation and removal |

| ATEX (94/9/EC) Group II, Category 2 documentation— by specific order | • Suitable for use in potentially explosive environments |

| Minimum/Maximum Design Pressure 1, 2 |

Liquids: -1 to 8 barg (-14.5 to 116 psig) Gases: -1 to 3.5 barg (-14.5 to 50.8 psig) |

|

| Minimum/Maximum Operating Temperature1 |

-10 to 150 °C (14 to 302 °F) | |

| Materials of Construction | Wetted parts 1.4404 (AISI 316L stainless steel) | |

| Sealing Materials 3 | EPDM elastomer | |

| Internal Surface Finish | Housing | ‹_ 0.8 micrometers Ra ( ‹_ 32 Ra microinches ), electropolished |

| Piping | ‹_ 0.8 micrometers Ra ( ‹_ 32 Ra microinches ) | |

| Internal Welds | Housing | Dressed and blended to provide uniform ripple- and crevice-free surface to ≤ 0.8 micrometers Ra (≤ 32 Ra microinches), electropolished |

| Piping | Weld finish is as welded, with a uniform, crevice-free profile. ≤ 1.6 micrometers Ra (≤ 63 Ra microinches), pickled and passivated or bright annealed | |

| Connections | Inlet/Outlet | DN65 (DIN 11851) 2.5 inch ISO 2852 clamp coupling compatible adaptors available by specific order |

| Feed Fluid Vent | DN6 (8 mm / 0.31 inch OD) hose tail | |

| Filtrate Vent (optional) | DN6 (8 mm / 0.31 inch OD) hose tail | |

| Drains – Piping Drain – Safety Valve |

DN15 (18 mm / 0.71 inch OD) hose tail; DN32 (DIN 11850) |

|

| Filter Module Compatibility 4 | SUPRApak L series modules | |

1 |

Maximum design pressure and temperature ratings are vessel ratings only. Safe operation will also depend on filter module and housing gasket use. EPDM assembly seals restrict continuous operating temperature to 130 ºC (266 ºF). For details on module temperature limitations, please refer to SUPRApak module literature. |

2 |

Design satisfies EC Pressure Equipment Directive (PED) 97/23/EC (Fluid Group 2, Category II, Module H). Pressure rating is suitable for non-hazardous liquids or gases. The PED category and fluid group classification indicates suitability of housing use on distilled spirits less than 70% by weight absolute alcohol. For such applications, the maximum allowable temperature must be below the flash point. For 70% by weight absolute alcohol the flashpoint is 21 ºC (69.8 ºF). |

3 |

Seal materials meet requirements for food contact use as detailed in FDA 21 CFR Section 177.2600, and EC Regulation 1935/2004, including BfR XV and XXI. Please contact Pall for additional options. |

4 |

Refer to Pall Food and Beverage SUPRApak module literature for additional guidelines on use. |

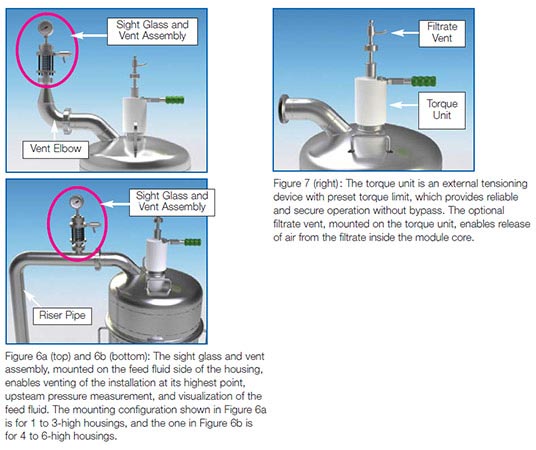

SUPRApak L Series-SA systems are supplied with standard accessories, which include different components depending on the housing height.

1 to 3-High Housings:

- An inlet and an outlet butterfly valve, a safety device with drain assembly, a feed fluid vent assembly including sight glass, vent and pressure gauge, a downstream drain assembly with pressure gauge, and a downstream non-return valve

4 to 6-High Housings:

- Two inlet and one outlet butterfly valves, a safety device with drain assembly, a vertical riser pipe with feed fluid vent assembly including sight glass, vent and pressure gauge, a downstream drain assembly with pressure gauge, and a downstream non-return valve

For additional accessories, see Optional Accessories.

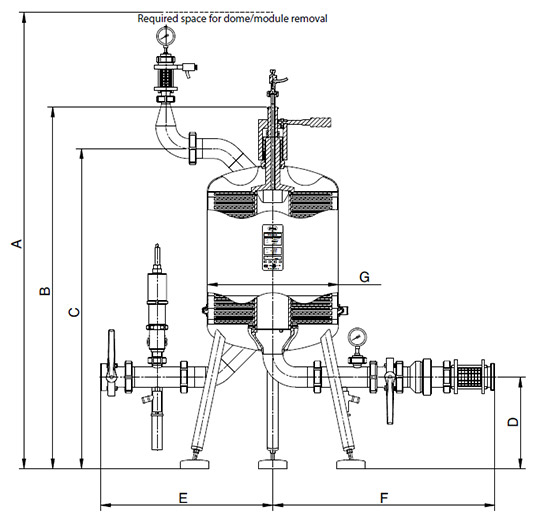

Figure 1: Dimensional information, 1 to 3-high housings

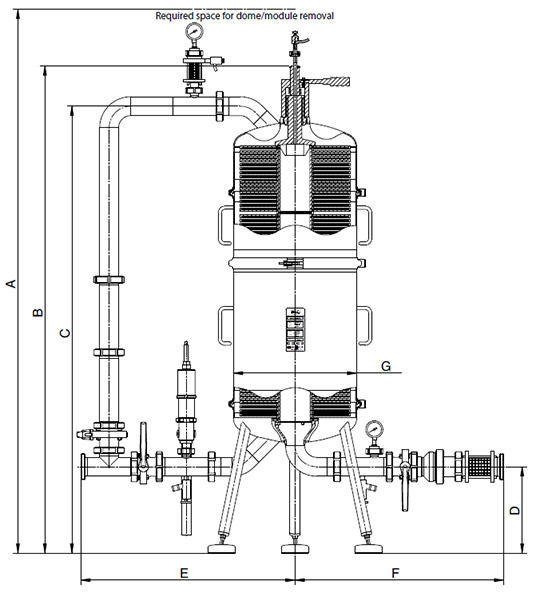

Figure 2: Dimensional information, 4 to 6-high housings

Nominal Dimensions in mm (inches) —

For specific dimensions, please contact Pall 5.

1

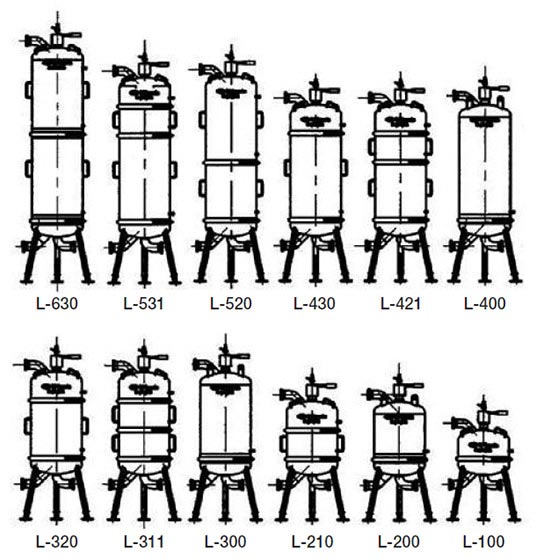

| L-100 | L-200 L-210 |

L-300 L-311 L-320 |

L-400 L-421 L-430 |

L-520 L-531 |

L-630 L-632 |

|

| A | 1337 (52.6) | 1827 ( 71.9) | 2333 (91.9) | 2870 (113) | 3604 (141.9) | 4113 (161.9) |

| B | 1017 (40) | 1277 (50.3) | 1537 (60.5) | 797 (70.7) | 2057 (81) | 2317 (91.2) |

| C | 872 (34.3) | 1132 (44.6) | 1392 (54.8) | 1652 (65.0) | 1912 (75.3) | 2172 (85.5) |

| D6 | 320 (12.6) | 320 (12.6) | 320 (12.6) | 320 (12.6) | 320 (12.6) | 320 (12.6) |

| E7 | 600 (23.6) | 600 (23.6) | 600 (23.6) | 794 (31.3) | 794 (31.3) | 794 (31.3) |

| F7,8 | 773 (30.4) | 773 (30.4) | 773 (30.4) | 773 (30.4) | 773 (30.4) | 773 (30.4) |

| G | 457.2 (18) | 457.2 (18) | 457.2 (18) | 457.2 (18) | 457.2 (18) | 457.2 (18) |

| 5 | Pall Corporation reserves the right to make dimensional modifications at any time, maintaining the same fit, form, and function. Please request a general arrangement drawing if exact dimensions are required. |

| 6 | Adjustable (leg height adjustment) |

| 7 | Indicated dimensions are for installations requiring DIN connections. For installations requiring clamp coupling connections, an optional DIN to clamp coupling adaptor is additionally available. See Optional Accessories. If adaptors are added to the inlet and outlet connections, add 85.3 mm (3.4 in) for each adaptor to the pipeline length. |

| 8 | Dimension includes optional pipeline sight glass. Subtract 162 mm (6.4 in) from this dimension for installations without sight glass. |

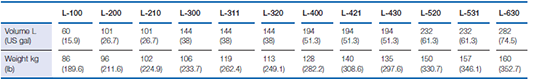

Volume and Weight9

9Volumes and weights include housing, pipework, standard accessories.

Standard Documentation10

- Certificate of Conformity to Quality Standards

- Final Inspection Certificate

- Installation/Operating Manual (IOM)

10Additional documentation packages can be ordered. Please request PPD004BRONZ, PPD004SILVER, or PPD004GOLD

Part Number: SPL SA [Table 1] [Table 2] [Table 3]

Example Part Number: SPLSA421TVA

Note:See bold reference codes in the tables.

Table 1

| Code | Bowl Height and Configuration | Number of SUPRApak Modules |

| 100 | 1-High Bowl | 1 |

| 200 | 2-High Bowl | 2 |

| 210 | 2-High Split Bowl | 1 or 2 |

| 300 | 3-High Bowl | 3 |

| 311 | 3-High Split Bowl | 1, 2, or 3 |

| 400 | 4-High Bowl | 4 |

| 421 | 4-High Split Bowl | 1, 2, 3, or 4 |

| 430 | 4-High Split Bowl | 1 or 4 |

| 520 | 5-High Split Bow | 3 or 5 |

| 531 | 5-High Split Bowl | 1, 2, 4, or 5 |

| 630 | 6-High Split Bowl | 3 or 6 |

| 632 | 6-High Split Bowl | 1, 3, 4, or 6 |

Table 2

| Code | Filtrate Vent Option |

| TW | No vent |

| TV | With vent, DN6 hose tail |

Table 3

| Code | ATEX Documentation |

| A | ATEX (94/9/EC) Classification: Group II, Category 2, (Zones 1/21 and 2/22) Documentation |

| N | No ATEX Documentation |

Optional Accessories

| Part No. | Description | Details |

| ACS1035AA | Sight Glass DN65 | For filtrate piping |

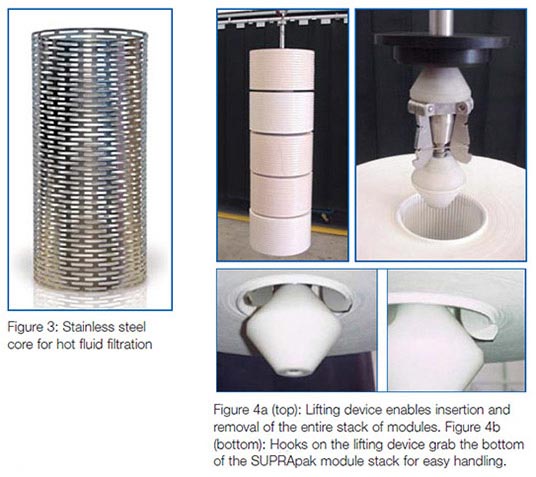

| 25590-022611 | Hot Fluid Core | 1.4404 (AISI 316L SS) |

| 25590-0226-0111 | Hot Fluid Core Extension Z1 | 1.4404 (AISI 316L SS) |

| 25590-0226-0211 | Hot Fluid Core Extension Z2 | 1.4404 (AISI 316L SS) |

| ACS1036AA | Hook Spanner DN10-20 | Tool |

| ACS1037AA | Hook Spanner DN25-100 | Tool |

| 20040118-12 | 1-2 High Lifting Device | Supplied with spacer |

| 20040118-34 | 3-4 High Lifting Device | Supplied with spacer |

| 20040118-56 | 5-6 High Lifting Device | Supplied with spacer |

| ACS1116AA | Maintenance Tool Kit | Hook spanners, adjustable torque wrench, torque unit tools |

| ACS1034GM | Inlet/Outlet Adaptor (DN65 – 2 ½ inch clamp coupling) | Adaptor for piping adaption from DN to ISO 2852 clamp coupling connection |

11For hot fluid filtration (>40 °C/ >104 °F) select Hot Fluid Core for the top module in the stack and add Hot Fluid Core Extension Z1 (1-high section) and/or Hot Fluid Core Extension Z2 (2-high section) as required. A 1-high housing will only require the Hot Fluid Core.

Spare Parts

| ACS1038AA12,14 | Housing Z1 Extension | Extension piece only |

| ACS1030AM12,14 | Housing Z1 Extension Kit | Extension piece, housing clamp, o-ring |

| ACS1030AM12,14 | Housing Z1 Extension Kit | Extension piece, housing clamp, o-ring |

| ACS1032AM12,14 | Housing Z3 Extension Kit | Extension piece, housing clamp, o-ring |

| ACS1054AA13 | Riser Pipe 1-High Extension Kit | 1-high pipe extension, for 4 or 5-high housings only, when required |

| ACS1055AA13 | Riser Pipe 2-High Extension Kit | 2-high pipe extension, for 4-high housings only, when required |

| ACS1033AM14 | Housing Closure Clamp Kit | Housing closure clamp, 1.4301 (AISI 304 SS) and o-ring, EPDM elastomer |

| ACS1039EM14 | Housing O-Ring | EPDM elastomer |

| ACS0951AM | Pressure Gauge DN25 | For feed fluid and filtrate piping |

| ACS1045AA | Sight glass DN25 and Vent DN6 Assembly | Kit including sight glass, feed fluid vent, pressure gauge |

| ACS1047CA | Butterfly Valve DN65 | For feed fluid and filtrate piping |

| ACS1035AA | Sight Glass DN65 | For filtrate piping |

| ACS1049AA | Non-Return Valve DN65 | For filtrate piping |

| ACS1086EX | Safety Valve DN25/32 | For feed fluid piping |

| ACS1050EA | DN65 Seal | EPDM elastomer, for piping |

| ACS1085AX | DN65 Seal Kit | EPDM elastomer kit, for butterfly valves |

| ACS1051EA | DN32 Seal | EPDM elastomer, for safety valve |

| ACS1052EA | DN25 Seal | EPDM elastomer, for pressure gauges |

| ACS1083EA | DN15 Seal Kit | EPDM elastomer kit, for drain valves |

| ACS1081EA | DN10 Seal | EPDM elastomer, for piping to filtrate vent |

| ACS1082EA | DN6 Seal Kit | EPDM elastomer kit, for feed fluid and filtrate vent valves |

| ACS1046AA | Vent Elbow DN65/DN25 | For 1-3 high housings only |

| ACS1053AA | Torque Unit (unvented) | Torque unit without filtrate vent |

| ACS1040AA | Torque Unit (vented) | Torque unit with filtrate vent |

| ACS1106EX | Torque Unit Rod Seal | EPDM elastomer |

| ACS1042AA | Torque Wrench | Torque unit spare part |

| ACS1043AA | Torque Unit Guide Bush | Torque unit spare part |

| ACS1044AA | Torque Unit Clamp Nut | Torque unit spare part |

| KCA69045 | Circlip | Torque unit spare part |

12 |

The PED Category 2 Module H classification limits the maximum allowable housing height to 6-high. New extension additions, which result in 4 to 6-high housings will require the incorporation of a suitable riser pipe assembly. Please consult Pall for best options. |

13 |

Order with Z1 or Z2 extension kits for 4 or 5-high housings, to complete riser pipe assembly. |

14 |

Please provide housing serial number when requesting these spare parts. |

We appreciate your review of this product. Please login to your account to leave a review.