SUPRApak™ S Series Filter Housings

Datasheets

Download:For Small Batch Depth Filtration

SUPRApak S series filter housings are designed for use with SUPRApak S filter modules, to handle small batch, high value food and beverage filtration applications.SUPRApak S series filtration units provide a closed system approach to high capacity depth filtration, maximizing product protection and minimizing product losses.

SUPRApak S units hold one SUPRApak module (Figure 1), representing about 0.5 m2 (5.4 ft2) of filtration area in a very compact and low hold-up volume design.

The units also provide a logical choice for carrying out small-scale pilot trials, to demonstrate the operation and benefits of this revolutionary alternative to classical flat sheet filtration.

| Features | Benefits |

| Closed filtration system | Increased process safety and product quality; no drip losses; minimum operator exposure to process fluids |

| Compact design accommodates high sheet area | High throughput filtration for small batch production |

| Drainable, low hold-up volume assembly | Higher product yield; minimized cleaning costs |

| High quality surface finish, sanitary and crevice-free design | Enhanced cleanability |

| Clamp coupling housing closure | Ease of handling during filter change-out and cleaning |

| Simple, quick installation and servicing | Reduced labor and maintenance costs; reduced process downtime |

| ATEX (94/9/EC) Group II Category 2 certification available | Suitable for use in potentially explosive environments |

| Minimum / Maximum Operating Pressure1, 2 | -1 to 6 barg (-14.5 to 87 psig) | |

| Minimum / Maximum Operating Temperature1 | -10 to 130 °C (14 to 266 °F) | |

| Materials of Construction | Wetted parts 1.4404 (AISI 316L stainless steel) | |

| Sealing Materials3 | EPDM elastomer | |

| Internal Surface Finish | ≤ 0.8 micron Ra (≤ 32 Ra microinches), electropolished | |

| Internal Welds | Dressed and blended to provide uniform ripple and crevice-free surface to ≤ 0.8 micron Ra (≤ 32 Ra microinches) | |

| Connections | Inlet/Outlet | DN 25 (DIN 11851) 1 inch sanitary clamp coupling (ISO 2852) |

| Vent | DN 6 (6 mm / 0.24 inch) OD hose nipple | |

| Drain (optional) | DN 6 (6 mm / 0.24 inch) OD hose nipple | |

| Filter Module Compatibility4 | SUPRApak S series modules | |

1 Maximum operating pressure and temperature ratings are vessel ratings only. Safe operation will also depend on filter module use. For compatibility details, please contact Pall.

2 Design satisfies EC Pressure Equipment Directive (PED) 97/23/EC (Fluid Group 1, Category I). Pressure rating is for liquid or gas.

3 Seal materials meet requirements for food contact use as detailed in FDA 21 CFR Section 177.2600, and EC Regulation 1935/2004. Please contact Pall for additional options.

4 Refer to Pall Food and Beverage SUPRApak module literature for additional guidelines on use.

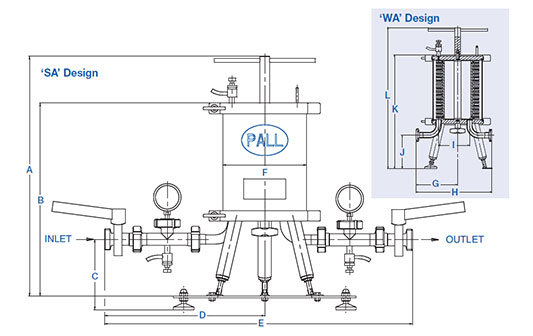

SUPRApak S housings are provided in ‘WA' or ‘SA' design.

The ‘SA' design includes a standard accessory package.

Nominal Dimensions in mm (inches) — for specific dimensions, please contact Pall5

| A | B | C | D | E | F | G | H6 | I | J | K | L |

| 596 (23.5) | 478 18.8) | 172 (6.8) | 377 (14.8) | 718 (28.3) | 207 (8.1) | 176 (6.9) | 317 (12.5) | 134.5 (5.3) | 140 (5.5) | 478 (18.8) | 596 (23.5) |

5 Pall Corporation reserves the right to make dimensional modifications at any time, maintaining the same fit, form and function. Please request a general arrangement drawing if exact dimensions are required.

6 Indicated dimension is for DIN 11851 connection. Dimension for clamp coupling version is 302 (11.9).

Volume and Weight

| Volume | Housing without accessories | 8 L (2.1 US gal) |

| Weight | Housing without accessories | 20 kg (44 lbs) |

| Housing with standard accessories | 28.6 kg (62.9 lbs) | |

| Base plate | 7 kg (15.4 lbs) | |

Standard Documentation

- Declaration of Conformity for CE Marking

- Certificate of Conformity to PED

- Certificate of surface finish

- Installation / Operating Manual (IOM)

- ATEX Certificate

Housings, Vessels, or Assemblies

This is a guide to the part numbering structure and possible options only.

For availability of specific options, please contact Pall.

Example Part Number: SPS WA 23 0 0

Example Part Number: SPS SA NW25 B D

For availability of specific options, please contact Pall.

‘WA' Design

Part Number: SPS WA [Table 1] [Table 2] 0Example Part Number: SPS WA 23 0 0

Note: See bold reference codes in the tables

Table 1

| Code | Inlet /Outlet Connection Type |

| NW25 | DN 25 DIN 11851 |

| 23 | 1 inch clamp coupling (ISO 2852) |

Table 2

| Code | Base Plate |

| 0 | Without base plate |

| B | With base plate |

‘SA' Design7

Part Number: SPS SA NW25 [Table 1] [Table 2]Example Part Number: SPS SA NW25 B D

Note: See bold reference codes in the tables

Table 1

| Code | Base Plate |

| 0 | Without base plate |

| B | With base plate |

Table 2

| Code | Base Plate |

| 0 | Without drain valves |

| D | With drain valves |

7 The standard accessory package is only available with DN 25 DIN 11851 connections and includes diaphragm pressure gauges (2) and butterfly valves (2) for the feed and filtrate sides of the housing.

Spare Parts and Accessories

| Part No. | Description | Details |

| ACS1002EM | Housing O-Ring Kit | EPDM (housing o-ring and tensioning shaft seals) |

| ACS1003EM | Housing O-Ring Kit | Fluorocarbon (housing o-ring and tensioning shaft seals) |

| ACS1000AM | DN 25 Seal Ring (6 pcs) | DN25 DIN 11851 EPDM |

| ACS1001AM | DN 25 Seal Ring (6 pcs) | DN25 DIN 11851 Fluorocarbon |

| SAN1TS23J | 1 inch sanitary gasket (10 pcs) | EPDM |

| SAN1TS23H | 1 inch sanitary gasket (10 pcs) | Fluorocarbon |

| ACS0700FA | DN 25 pressure gauge | DN25 DIN 11851 diaphragm pressure gauge |

| 25590-0226-01 | SUPRApak Hot fluid core (Z1)8 | Stainless steel core |

| ACS1037AA | Hook Spanner (DN 25-100) | Tool |

8 Required for continuous hot fluid filtration (> 40 oC / > 104 °F ). See Figure 4.

We appreciate your review of this product. Please login to your account to leave a review.