Pall PMM metal membrane media combine the best qualities of Pall's PSS and Rigimesh media by incorporating a thin matrix of ultra-fine stainless steel powders sintered within the pore structures of fine sintered stainless steel woven wire mesh. This combination of technologies enables production of highly permeable metal membranes with greater strength and finer grades than either method alone. PMM media can be pleated to form double open-ended (DOE) MBS1000 style membrane filter cartridges with high area and fine ratings making it an excellent choice for steam service and other fine solids recovery/removal applications in both liquid and gas applications.

Features

- All-stainless steel construction

- Controlled and fixed pore size

- High area pleated cartridges

- Efficiencies to 2 µm absolute in liquids

- Ultra-clean steam service

- Efficient cake formation and solids recovery

- Corrosion resistant

- High pressure resistant

- Withstands high reverse-flows

- High-temperature capabilities

- Repeatedly cleanable

- No soluble polymeric extractables

- No unloading or shedding

- Absolute rated for reliable performance

- ISO 9000 Certified Quality System

- Manufactured for use in conformance with cGMP

- FDA-listed materials per 21 CFR

Materials of Construction

- Medium Type 316L stainless steel1

- End Caps Type 304 stainless steel1

- Gasket Buna-N (standard)2

Configuration3

- Double open-ended (DOE), flat gasket seals

Nominal Dimensions

- Diameters 2.5 in. (64 mm)

Operating Conditions

- Maximum Differential Pressure and Temperature4

Forward Flow Direction: 8.6 bard (125 psid) to 232 °C (450 °F)

Reverse Flow Direction: 0.7 bard (10 psid) to 232 °C (450 °F)

Recommended Maximum Flow Densities5

| Grade | Aqueous L/min (gal/min) | Air Nm3/hr (acfm) |

| M200 | 1.4 (0.37) | 4.7 (30) |

| M150 | 1.1 (0.29) | 3.9 (25) |

| M100 | 0.4 (0.1) | 3.2 (20) |

| M050 | 0.3 (0.08) | 1.6 (10) |

| M020 | 0.3 (0.08) | 1.6 (10) |

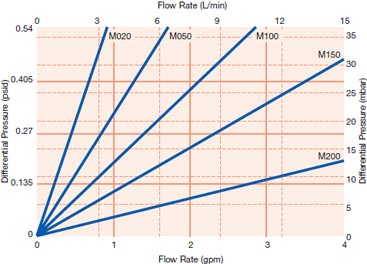

Typical Liquid Flow Rates6

1Other grades and alloys available.

2Other polymers available.

3Single open-ended AB sanitary and threaded styles available.

4Minimum collapse differential pressure. Limit with Buna-N gaskets: 121 °C (250 °F). Other gasket materials to 232 °C (450 °F). For Reinforced for 3.4 bard (50 psid) Reverse Flow option, temperatures to 316 °C (600 °F), or in other alloys to 677 °C (1250 °F), contact your local Pall distributor.

5Ratings are absolute particulate in liquids and gases. Aqueous (water, 1 cp) and air flows per 10 in. (254 mm) cartridge.

6Typical initial clean medium ∆P per 10 in. (254 mm) element, water at 20 °C (68 °F), 1 cp. For assistance in sizing and housing selection, contact your local Pall representative.

Metal Filters

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall. Example Part Number: MBS100 3 M200 H (See bold references in tables below) Part Number: MBS100 < Length Code from Table 1 > < Rating Code from Table 2 > < Gasket Code from Table 3 >

9Based on modified P2 efficiency tesst, removal efficiency by particle count

Table 1 - Length Code

| Code | Nominal Length | Filter Area |

| 1 | 10 in. (254 mm) | 0.14 m2 (1.5 ft2) |

| 2 | 20 in. (508 mm) | 0.28 m2 (3.0 ft2) |

| 3 | 30 in. (762 mm) | 0.42 m2 (4.5 ft2) |

| 4 | 40 in. (1016 mm) | 0.56 m2 (6.0 ft2) |

Table 2 - PMM Medium Removal Effciency (in Microns)

| Media Grade | Removal Ratings | ||||

| Liquid Service9 | Gaseous Service10 | ||||

| 90% | 99% | 100% | Weight % Removal | 100% | |

| M020 | 0.1 | 0.5 | 2 | >99.99 | 0.4 |

| M050 | 0.6 | 2 | 5 | 99.99 | 0.6 |

| M100 | 2 | 5 | 10 | 99.97 | 1.3 |

| M150 | 5 | 9 | 15 | 99.96 | 2.5 |

| M200 | 8 | 13 | 20 | 99.93 | 4.0 |

| M250 | 10 | 16 | 25 | 99.90 | 9.0 |

Table 3 - Gasket Options

| Code | Gasket Options |

| H13 | Buna-N gaskets (Standard) |

| H | Viton8 |

| J | Ethylene Propylene |

| J7 | Ethylene Propylene (Steam Service) |

9Based on modified P2 efficiency tesst, removal efficiency by particle count

10Weight percent removal data based on AC Fine Test Dust in air. Absolute retention ratings based on actual particle count data.

We appreciate your review of this product. Please login to your account to leave a review.