Documents

Datasheets

Download:Description

Jacketed Filter Housings are fabricated with either T-Type or In-Line flow designs and AB style Code 7 fitting configurations for single open-ended (SOE) sanitary AB style filter cartridges. They offer the added feature of a 316L stainless steel jacket for temperature control using hot water or steam, and are suitable for gas service or liquid flows to 20 gal/min (75 L/min) with minimal pressure drops.

Features

- Corrosion resistant 316 L Stainless steel jacket for temperature control

- In-Line or T-Type flow designs

- Entire housing electropolished

- Internal surfaces with < 0.4 µm (< 15 µin.) Ra surface finish

- External surfaces with < 0.8 µm (< 32 µin.) Ra surface finish

- Low hold-up volume - maximizes product recovery

- Easy-draining features, including downward sloping internal contour and low-point drain - allows easy removal of CIP solution or product

- Fewer welds - results in an extremely sanitary design

- Automated orbital welding - produces consistent high quality welds

- Non-rotating vent and drain - prevent twisted hoses and allow hard piping

- Manufactured for use in conformance with cGMP

- 3-A Sanitary Standard Symbol for optimized CIP/cleanable design

- Manufacturing Quality System Certified to ISO 9000 Standards

Specifications

Materials of Construction

- Housing: 316L stainless steel

- Jacket: 4.9 barg at 140 °C (72 psig at 284 °F)

- Inlet and Outlet Connections: 1 1⁄2 in sanitary coupling

- Jacket: 1⁄2 in. NPT

- Standard Gasket O-ring Material: Ethylene Propylene

Design Pressure and Temperature

- 10 barg at 140 °C (150 psig at 284 °F)

Jacket

- 4.9 barg at 140 °C (72 psig at 284 °F)

Nominal Diameter

- 114.5 mm (4 1⁄2 in.)

Number of Cartridges

- 1

Cartridge Style

- AB Code 7

Legs and Support

- ALT: Stand available

- ALI: None

- Closure Style: Vee-band clamp

Flow Configuration

- ALT: Tee

- ALI: In-Line

Operating Conditions

- Maximum Operating Pressure: -11 to 10 barg (-14.51 to 1502 psig)

- Maximum Operating Temperature: 150 °C (300 °F)

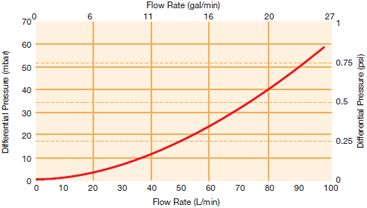

Typical Water Flow Rates

1Full vacuum.

2With compatible fluids, which do not soften, swell or adversely affect the gasket materials.

Type

Housings, Vessels, or Assemblies

Ordering Information

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Example Part Numbers:

ALT1 1 J23 B N H4

ALI1 1 J23L B N H4

(See bold references in tables below) Part Number: ALT1/ALI1 < Cartridge Code from Table 1 > J23/J23L < Vent Code from Table 2 > < Drain Code from Table 3 > H4

ALT1 1 J23 B N H4

ALI1 1 J23L B N H4

(See bold references in tables below) Part Number: ALT1/ALI1 < Cartridge Code from Table 1 > J23/J23L < Vent Code from Table 2 > < Drain Code from Table 3 > H4

Table 1 - Cartridge Type

| Code | Cartridge Type |

| 1 | AB1 code 7 |

| 2 | AB2 code 7 |

| 3 | AB3 code 7 |

| 4 | AB4 code 7 |

Table 2 - Vent

| Code | Vent |

| A | Sanitary valve with quick-release coupling |

| B | Sanitary valve with 8 mm (0.314 in.) hosetail |

| C | ISO 2037/BS 4825 with side sanitary valve with quick release fitting for Stäubli type coupling |

| D | 1⁄2 in. sanitary flange to ISO 2037/BS 4825 |

| N | None |

Table 3 - Drain

| Code | Drain |

| B | Sanitary valve with 8 mm (0.314 in.) hosetail |

| D | 1⁄2 in. sanitary flange to ISO 2037/BS 4825 |

| N | None |

Reviews

We appreciate your review of this product. Please login to your account to leave a review.