Datasheets

Download:A cost effective design for sanitary applications

The Membralox HCS module range takes advantage of the unique hexagonal shape of the Membralox ceramic membranes to obtain a high membrane packing density, thus significantly reducing filtration system costs.

The Membralox HCS modules perfectly match reliability and cost requirements of the main applications in sanitary industries.

Membralox HCS module range features internal gasketing and assembly designed according to high sanitary standard.

Membralox filtration modules are the corner stone for process reliability.

The Widest Separation Range

The exceptional structure of Membralox filtering elements has enabled the development of the widest range of micro and ultrafiltration ceramic membranes. A complete range of modules help for scale-up from laboratory separations to full size industrial needs.

Cost Effective Separations

The remarkable physical and chemical stability of Membralox membranes allows reproducible performance over a long life—a key feature in a cost/benefit analysis proven in numerous industrial installations.

Applications Examples

- Clarification of fermentation broth

- Sugar and sweetener processing

- Fruit juices clarification

- Milk & whey processing

- Beer tank bottoms recovery

Membralox HCS Modules

- Highly compact for cost effective system design and small footprint

- All wetted parts fully accessible to cleaning chemicals during CIP (no dead zone)

- Reduced permeate hold up volume

- Proprietary built-in gasketing solution to ensure perfect sealing

- Wide chemical compatibility

- Long service life

Membralox Ceramic Membranes

- High flux

- Proven long operational life

- Excellent resistance to corrosion

- Wide chemical and pH (0-14) compatibility

- Excellent thermal stability

- Sanitizable

- Ability to withstand high frequency backpulsing cycles

- Meet FDA requirements detailed in 21 CFR

- 100% bubble point integrity tested

- Customized membrane configurations can also be proposed for the most demanding applications

Pall Membralox HCS Modules Range

| Module Type | Number of membranes | Membrane type | Surface area (m2) | Retentate Connections (RC) Permeate Connections (PC) |

| M-36P4840 | 36 | EP4840 | 24.84 | RC: Bolt flanges / Sanitary o-ring seal PC: 2.5” sanitary tri-clamp |

| M-36P2760 | EP2760 | 18.00 | ||

| M-36P3740 | EP3740 | 16.81 | ||

| M-36P1960 | EP1960 | 12.96 | ||

| M-60P3730 | 60 | EP3730 | 21.00 | |

| M-60P1940 | EP1940 | 14.40 | ||

Pall Membralox Ceramic Membrane Type

| Membrane Type | EP3730 | EP1940 | EP3740 | EP4840 | EP1960 | EP2760 |

| Channel diameter (mm) | 3 | 4 | 4 | 4 | 6 | 6 |

| Number of channels | 37 | 19 | 37 | 48 | 19 | 27 |

| Filtration area (m2) | 0.35 | 0.24 | 0.47 | 0.69 | 0.36 | 0.50 |

| Length (mm) | 1020 | 1020 | 1020 | 1020 | 1020 | 1020 |

The Membralox membrane support (12 μm pore size) and the membrane end sealing are made of sintered ultrapure alpha-Alumina.

Pall Membralox Membrane Pore Sizes1

| Microfiltration | 1,4* -0,8* -0,5 -0,2 -01* μm | alpha-alumina |

| Ultrafiltration | 100* -50 -20 -10 nm | Zirconia |

1 Some pore sizes are not available on all membrane geometries. Please check with your Pall representative for further information.

*Available in Membralox GP membrane type. 0,8 and 1,4 μm are available in double layer format.

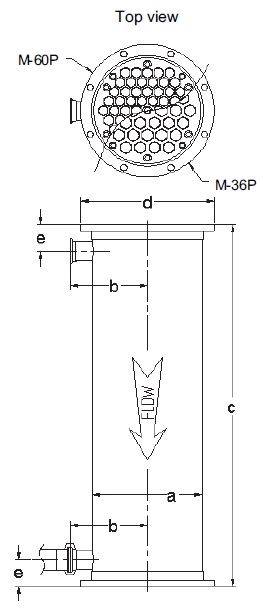

Membralox HCS Modules View

Nominal Dimensions

| Dimensions | a | b | c | d | e | |

| M-36P /M-60P | 340 | 237 | 1126 | 417 | 83.5 | |

Operating Limits in Aqueous Liquids2

| Temperature | 95 °C |

| Pressure | 10 bar** |

2 Any liquids belonging to group II from PED 2014/68/EU art. 4-§3

**1 bar = 100kPa

Applications

- Clarification of fermentation broth

- Sugar and sweetener processing

- Fruit juices clarification

- Milk & whey processing

- Beer tank bottoms recovery

- High flux

- Proven long operational life

- Excellent resistance to corrosion

- Wide chemical and pH (0-14) compatibility

- Excellent thermal stability

- Sanitizable

- Ability to withstand high frequency backpulsing cycles

- Meet FDA requirements detailed in 21 CFR

- 100% bubble point integrity tested

- Customized membrane configurations can also be proposed for the most demanding applications

Accessories and Complementary Services

- Backpulse devices

- Laboratory scale and benchtop pilot units

- Feasibility studies, on-site plant design, commissioning, tests, training courses

The limits of use of Membralox modules are determined mainly by the type of housing or gasket materials. Based on valuable pilot test data, our Scientific and Laboratory Services can provide advice in selecting the best membrane and module configuration to match your process requirements.

Accessories and Complementary Services

- Backpulse devices

- Permeate flow regulators

- Laboratory scale and benchtop pilot units

- In-house feasibility studies, on-site plant design, commissioning, tests, training courses

We appreciate your review of this product. Please login to your account to leave a review.