Emflon® PFRW Kleenpak™ Capsules

Datasheets

Download:For Small Scale Sterile Filtration of Gases

Pall Kleenpak capsules combine Pall’s proprietary Emflon PFRW membranes for sterilizing filtration of air and gases with specially designed self-contained assemblies, to achieve filtration security and user convenience in small scale compressed gas and vent applications.

Description

At the heart of every Kleenpak Emflon PFRW capsule are Pall’s advanced 0.2 micron rated polytetrafluoroethylene (PTFE) double-layer membranes, which provide high performance sterilization of gases. The robust PTFE membranes are inherently hydrophobic, and designed specifically for reliable removal of bacteria and bacteriophage.

These filters fulfill a microbial liquid bacteria challenge validation according to guidelines for sterilizing grade gas filters, and have a particulate removal rating of 0.003 micron in gases. They provide sterile effluent, ensuring process security.

The Kleenpak capsule uses well-proven proprietary Pall techniques for filter construction and heat sealing, to ensure highest possible security against filter bypass, even under conditions of pulsed flow. It is designed to withstand multiple autoclave cycles over the life of the filter. The capsule configuration includes a 38 mm (1.5 inch) sanitary clamp coupling connection to allow for easy installation into existing pipework.

Features and Benefits

| Features | Benefits |

| Robust self-contained assembly with clamp coupling connections for direct installation into the process |

|

| High performance Emflon PFRW sterilizing grade membranes |

|

| Multi-cycle autoclave robustness |

|

| High flow rates and low pressure drop |

|

| Absence of any glues, binder resins or surfactants |

|

| 100% integrity tested prior to dispatch |

|

| Individually serialized capsules |

|

Materials of Construction

| Component | Description |

| Filter Medium | Double-layer PTFE |

| Support / Drainage | Polypropylene |

| Cage, Core and End Cap | Polypropylene |

| Outer Shell | Polypropylene |

| O-ring Seal (Vent/Drain Valves) | Ethylene Propylene Rubber |

Technical Information

The technical information provided is based on controlled laboratory tests done on typical production filters at the conditions described, unless otherwise indicated. Actual operating conditions may affect the filter's performance.

Operating Characteristics in Compatible Gases1

| Maximum Supply Pressure | Operating Temperature |

| 3.5 bar (50.8 psig) | ≤ 40 °C (104 °F) |

1 Air, nitrogen, or other compatible gases.

Autoclave2

| Cumulative Autoclave Steaming Time | Operating Temperature |

| 50 hours | 140 °C (284 °F) |

2 Kleenpak filters must not be in situ steam sterilized by passing steam through under pressure, as this can result in rupture of the assembly. The figures are maximum allowable figures determined by testing under controlled laboratory conditions to the total number of hours indicated. Actual life time in use may vary.

Quality

- Cartridges produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Removal Performance

Emflon Kleenpak PFRW capsules provide sterile effluent3 when liquid challenged with Brevundimonas diminuta (ATCC 19146) microorganisms at ≥107 cfu /cm² effective filtration area.

Pall has an excellent history of use of the Emflon PTFE membrane used in the Emflon PFRW filters, see ‘Validation Guide for Pall Emflon PFR Filter Cartridges’, USTR2114 (2) further demonstrating:- Particulate removal rating of 0.003 micron in dry gases

- MS-2 and PP7 bacteriophage aerosol challenge

3 Where ‘sterile air' is defined as that filtered using a 0.2 μm liquid rated filter, capable of removing 107 of Brevundimonas diminuta per cm2 of effective filtration area, in laboratory tests

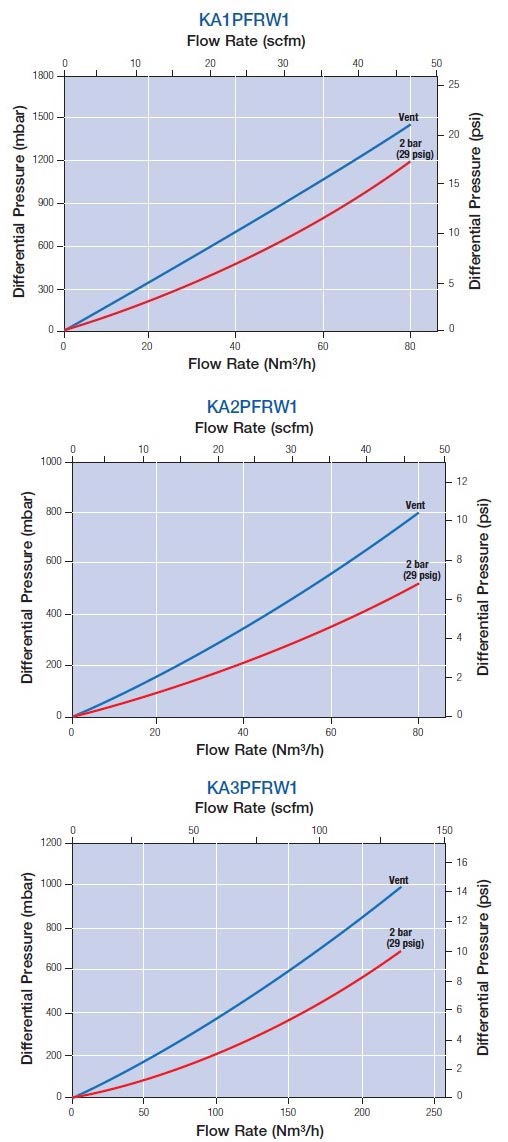

Typical Flow Rates4

4 Typical clean differential pressure per capsule, air at 20 °C (68 °F). For gases other than air please contact Pall for proper sizing.

This information is a guide to the part numbering structure.

Part Number: KA [Table 1] PFR W 1

Example Part Number: KA2PFRW1

See bold reference code in tables.

Table 1: Nominal Dimensions

| Code | Description | |||

| Length (mm)5 | Diameter (mm)6 | Diameter (mm)7 | Nominal Filter Area | |

| 1 | 117 | 61 | 94 | 0.04 m2 (0.45 ft2) |

| 2 | 158 | 61 | 94 | 0.08 m2 (0.95 ft2) |

| 3 | 174 | 76 | 110 | 0.23 m2 (2.48 ft2) |

5 Length including 38 mm (1.5 inch) sanitary connections

6 Excluding bleed valves (Figure 1)

7 Including bleed valves

Accessories

SAN1HA23J – 316 stainless steel 25.4 mm (1 inch) clamp coupling adaptor to hosetail fitting with ethylene propylene rubber seal

Figure 1: Bleed valves at vent/drain connections

We appreciate your review of this product. Please login to your account to leave a review.