Seitz® FA Series Depth Filter Sheets

Datasheets

Download:Fruit Juice Filter Solution

Seitz FA series depth filter sheets were developed to meet the production needs and requirements of the fruit juice industry and associated applications requiring thermoacidophilic bacteria (TAB) spore control.The FA filter sheets combine the process mechanisms of surface filtration, depth filtration, and adsorption to fulfill the specific requirements of fruit juice, juice concentrate, and ingredient manufacturers.

FA filter sheets are available in multiple grades suitable for polishing, clarification, and microbial reduction.

| Features | Benefits |

| Homogenous and consistent media, available in four grades |

|

| A combination of surface, depth, and adsorptive filtration |

|

| Each fruit juice filter sheet is laser etched with the sheet grade, batch number, and production date. | Full traceability |

Food Contact Compliance

- Food contact compliant filters are available. Please consult the Declarations of Compliance for applicable part numbers at the links below.

- Please refer to Food Contact Compliance and Safety for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Main Constituents

- Cellulose, diatomaceous earth (DE, Kieselguhr), perlite.

Characterization

| Grade | Mass per Unit Area g/m2 | Thickness mm |

Ash % |

Water Permeability2 L/m2/min (gal/ft2/min) |

| FA 05 | 1350 | 3.7 | 46 | 95 (2.3) |

| FA 10 | 1350 | 3.7 | 46 | 146 (3.6) |

| FA 20 | 1250 | 4.0 | 46 | 510 (12.5) |

| FA 30 | 1250 | 4.2 | 46 | 780 (18.9) |

These figures have been determined in accordance with in-house test methods and the methods of the Technical / Analytical Work Group within the European Depth Filtration Association.

2The permeability was measured under test conditions with clean water at 20 °C (68 °F) and a Δp of 1 bar (14.5 psi).

Regeneration

FA series filter sheets may be rinsed with clean water (in the forward or reverse3direction) to increase throughput and to optimize economic efficiency. Optimal regeneration of filter sheets installed in a plate and frame filter may be achieved with serial rinses of warm water followed by hot water. An example protocol is shown below.- Rinse with warm water (60 °C / 140 °F) for 15 minutes

- Rinse with hot water (70 – 80 °C / 158 – 176 °F) for 8 – 10 minutes

3When rinsing in the reverse flow direction it is critical to control particulate and microbial levels in the rinse water so that the filtrate side of the sheet is not contaminated. Water used for reverse flow flushes should be particle-free, and if the filter will not be sterilized prior to re-use the water should be free of microbes. Backwashing should be in a diagonal direction from outlet to inlet in a plate and frame filter.

Sterilization and Sanitization

| Method | Temperature °C (°F) |

Maximum Differential Pressure bar (psi) |

Time4/ Cycle min |

| Steam | 125 (257) | 0.5 (7.2) | 20 |

| Hot Water | 90 (194) | 1 (14.5) | 30 |

4 The actual time required may vary as a function of the process conditions.

Filtration Guidelines5

For achieving optimal filtrate quality, the following flow velocities and differential pressures should not be exceeded:| Grade | Flow Velocity L/m2/h (gal/ft2/h) |

Maximum Differential Pressure bar (psi) |

| FA 05 | 500 (12.3) | 1.5 (21.8) |

| FA 10 | 850 (20.9) | 3 (43.5) |

| FA 20 | 850 (20.9) | 3 (43.5) |

| FA 30 | 850 (20.9) | 3 (43.5) |

| Application | Grade | Flow Velocity for Concentrate L/m2/h (gal/ft2/h) |

Flow Velocity for Half Concentrate L/m2/h (gal/ft2/h) |

| Filtration prior to concentration |

FA 10 | 200-250 (4.9-6) |

400-500 (9.8-12.3) |

| Microbial reduction (low bacterial load) |

FA 05 | 200-250 (4.9-6) |

400-500 (9.8-12.3) |

| Microbial reduction (high bacterial load) |

FA 05 | 175-200 (4.3-4.9) |

350-400 (8.6-9.8) |

5Please contact Pall for recommendations on your specific filtration process as results may vary by product, pre-filtration and filtration conditions.

For additional operating guidelines, including rinsing of sheets prior to use, please refer to instructions provided by Pall.

| Grade | Application |

| FA 05 | Reduction of microorganisms prior to storage of fruit juices and concentrates or prior to final bottling |

| FA 10 | Polishing filtration of clear fruit juices prior to bottling, to achieve brilliant products, especially for apple juice filtration |

| FA 20 | Polishing filtration prior to bottling, when high throughputs are required |

| FA 30 | Clarifying filtration of colored juices such as red/black currant or cherry juice; clarifying filtration of apple juice |

Quality

- Filter sheets produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

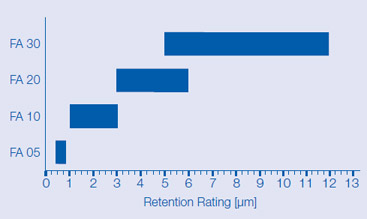

Relative Retention Rating1

1 Effective removal performance of filter sheets is dependent on process conditions.

Filter Sheets

Available Sheet Formats

Rectangular Sheets- 400 mm x 400 mm (15.8 in. x 15.8 in.)

- 600 mm x 612 mm (23.6 in. x 24.1 in.)

We appreciate your review of this product. Please login to your account to leave a review.