Datasheets

Download:For Beer Clarification and Stabilization

Pall’s

Description

The

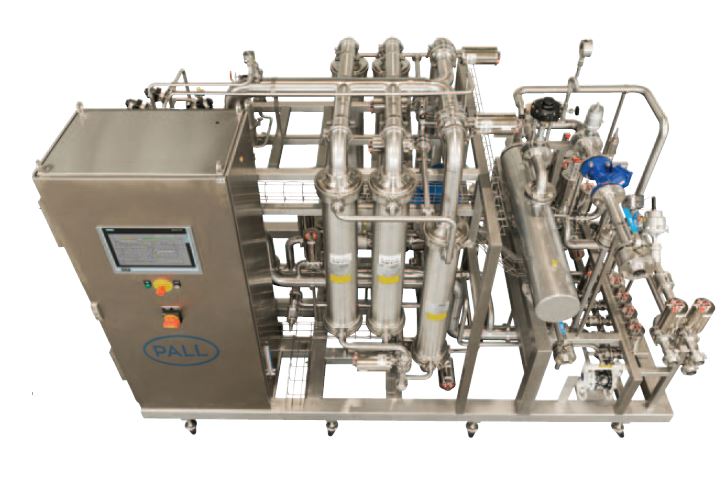

- Filter housings with membrane inserts

- Instrumentation and connection valves for beer, water, steam

and cleaner inlet and outlet - CIP capability including

heat exchanger, dosing pumps and water filter - Control cabinet and HMI for fully automated operation

| Features | Benefits |

| Cluster design with unique lower positioned end module |

|

| Cross failure test on membrane function prior to every filtration run |

|

| Forward flow principle |

|

| Patented Pall membrane design with stainless steel housing |

|

| Simple cleaning process |

|

| Plug and play standalone system |

|

The Impact of IoT on Performance and Consumption in Filtration

The implementation of IoT in the beer-making process supports transforming the industry towards sustainable and cost-effective production. With IoT based digitalization in filtration and stabilization , breweries can optimize processes, automate machine learning, and manage data for reporting, traceability, and analysis.

But IoT users have one primary concern in common – data security. Pall values data security as the highest priority and proactively takes all the necessary steps to remain best-in-class. Therefore, it is essential that the latest state-of-the-art technology protects brewery data with penetration tests and code scanning exercises to continuously identify risks and takes the necessary actions to ensure brewery data remains where it is needed.

Data Handling in the Brewery

A modern automated brewery generates and processes a large amount of data during operation. Process control is the primary use of a large portion of this data. A small amount of this goes toward process analysis and optimization.

Pall values data security as the highest priority and proactively takes all the necessary steps to remain best in class. Our goal is to provide an easy means of obtaining quantifiable data for brewing operations. Through Pall BeerIoT, brewers can optimize their operations, improve sustainability and quality initiatives, and improve their OpEx.

PROFi IoT

To gain maximum advantage from the data generated by a PROFi control system Pall implemented IoT-based real-time data management with constant access to valuable information across the organization in user-defined formats. The ability to benchmark against other installations within a brewery group and against the industry average is also available.

Typical examples of digital data analytics are:

- Specific consumption data: water, cleaning agents, electricity, membranes

- Performance data: degree of utilization, efficiency, and downtimes

- Quality data: oxygen uptake, color, original extract and haze

- notifications, alarms and messages

Documentation and service data

Pall IoT provides direct online availability of all system-specific documentation and training documents, spare parts lists, service reports, operating instructions, safety instructions and acceptance reports.

Technical Data

| PROFi Craft 6 | PROFi Craft 12 | |

| Typical flow rate (hl / h) | 30 – 80 | 80 –150 |

| System volume (l) | 300 | 380 |

| Max pressure (mbar/ psi) | 2,000 /29 | 2,000 /29 |

| Footprint (lwh) | 3220 x 1680 x 2305 | 3720 x 1680 x 2312 |

| Weight (kg / lbs) | 1,700 / 3748 | 1,950 / 4299 |

| Beer Connection | DN 50 | DN 65 |

| CE Mark | Yes | Yes |

Modules

Pall patented design including hollow fiber insert for usage in stainless-steel housings:

| Membrane Material | |

| Pore structure | Reverse |

| Pore size | 0.65 μm |

| Fiber diameter | 1.4 – 1.6 mm |

| Filter area /module | 12,3 m² |

| Typical flux | 50 – 80 l /m²h |

| Yeast removal rating% | 99.9998 |

Membrane Cleaning

- Cold and warm water flush at max 64 °C- chemical clean with 0.5 to 1% caustic at 64°C

- Regeneration step with Ultrasil CMF and Peroxide at 75 °C

- Integrity testing after each cleaning/regeneration

Total time water/caustic flush: 45 min

Total time complete cleaning: 90 min

The

Quality

Materials and Regulations

For specific

We appreciate your review of this product. Please login to your account to leave a review.