Datasheets

Download:Pall’s SUPRAdisc™ II Zero DE (ZD) module Series is a unique combination of Pall’s SUPRAdisc II design for lenticular sheet based modules and a pure cellulose depth filter sheet media for Food and Beverage applications. The filter has been designed to give excellent filtration performance and lower filtration costs.

The SUPRAdisc II ZD Series combines a 100% cellulose depth filter sheet matrix and Pall’s SUPRAdisc II design with its patented Inside-Outside Separator Technology that differentiates from classical stacked disc lenticulars in their filtration and handling characteristics. The SUPRAdisc II ZD filter media was developed to meet the need of the Food and Beverage Industry for filter sheet media, based on 100% pure cellulose fiber matrix material, without any use of Diatomateous Earth (DE) or Perlite. SUPRAdisc II ZD filter modules are available in multiple grades, suitable for microbial reduction, fine filtration and clarifying filtration in various Food & Beverage applications.

Features and Benefits

| Features | Benefits |

| 100% pure cellulose depth filter media: no inorganic components |

|

| highly fibrillated cellulose fiber matrix |

|

| SUPRAdisc II design with Inside-Outsides Separator Technology |

|

Food Contact Compliance

Please refer to the Pall website for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.

Conditioning

Prior to use, it is recommended to rinse the filter with clean water at ambient temperature with > 50 L/m².

Regeneration2

SUPRAdisc II ZD filter modules may be rinsed with clean water (in forward or reverse direction) to increase total throughput optimizing economic efficiency. Optimal regeneration of SUPRAdisc II ZD modules may be achieved with several rinses of cold water followed by warm water. An example protocol is shown below.

a. Rinse with cold water (ambient temperature) for 5 min.

b. Rinse with warm water (max. 60 °C / 140 °F) for 10 min.

Rinsing flow rate should be 1 ½ of the filtration flow rate with a counter pressure of 0.5-1 bar (7.2-14.5 psi).

2When rinsing in the reverse flow direction it is critical to control particulate and microbial levels of the rinsing water, so that the filtrate side of the sheet media is not contaminated. Water used for reverse flow flushes should be particle-free, and if the filter will not be sanitized prior to re-use the water should be free of microorganisms. The actual time required for optimal regeneration may vary as a function of the process conditions. Please contact Pall for recommendations on your specific filtration process as results may vary by product, pre-filtration and filtration conditions.

| Grade | Application |

| SUPRAdisc II ZDEK SUPRAdisc II ZD08 |

|

| SUPRAdisc II ZD10 SUPRAdisc II ZD25 |

|

Recommended Flow Rates and Differential Pressure

| SUPRAdisc II Grade | Application | Flow Rate Wine and other Beverages | Flow Rate Beer | Maximum Differential Pressure | ||

| [L/Module/h] (gal/Module/h) | [L/Module/h] (gal/Module/h) | [bar] [psi] | ||||

| 16" | 12" | 16" | 12" | |||

| 200ZDEK | Fine filtration; Filtration prior to final membrane filter | 2,625 (693) |

945 (250) |

600 (158) |

216 (57) |

1.5 (21.8) |

| 200ZD08 | ||||||

| 200ZD10 | Polishing Filtration; Particle Filtration | 4,250 (1,122) |

1,530 (404) |

750 (189) |

270 (71) |

2.5 (36.3) |

| 200ZD25 | ||||||

Available SUPRAdisc II Formats

SUPRAdisc II 12”, Single layer, 1.8 m² filter area, flat gasket

SUPRAdisc II 16”, Single layer, 5.0 m² filter area, flat gasket

Quality

SUPRAdisc ZD Filters are manufactured according to ISO 9001:2008 certified Quality Management System.

SUPRAdisc II Ordering Key

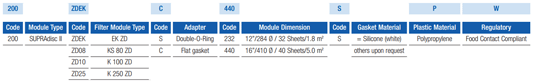

Example: [200] [ZDEK] [C] [440] [S] [P] [W]

= SUPRAdisc II, EK ZD Media, Flat Gasket, 16” (5.0 m²), Silicone Seal, PP Plastic Material, Food Contact Compliant

| SAP Ordering Code | Material Description | Sheet Media Size | |

| 7008378 | SUPRADISC SDZD II EK 200ZDEKC232SPW | EK-ZD | 12” |

| 7008379 | SUPRADISC SDZD II 80 200ZD08C232SPW | KS 80 ZD | 12” |

| 7008380 | SUPRADISC SDZD II 100 200ZD10C232SPW | K 100 ZD | 12” |

| 7008381 | SUPRADISC SDZD II 250 200ZD25C232SPW | K 250 ZD | 12” |

| 7008382 | SUPRADISC SDZD II EK 200ZDEKC440SPW | EK-ZD | 16” |

| 7008383 | SUPRADISC SDZD II 80 200ZD08C440SPW | KS 80 ZD | 16” |

| 7008384 | SUPRADISC SDZD II 100 200ZD10C440SPW | K 100 ZD | 16” |

| 7008385 | SUPRADISC SDZD II 250 200ZD25C440SPW | K 250 ZD | 16” |

We appreciate your review of this product. Please login to your account to leave a review.