0.2 Micron, Emflon® PFAW Hydrophobic Membrane Filter Cartridges

Datasheets

Download:For Bioburden Reduction in Dry Gases

Emflon PFAW cartridges are high capacity hydrophobic membrane filters designed for reliable reduction of particles and microorganisms in compressed gas and vent applications.The filter element features Pall’s proprietary 0.2 micron polytetrafluoroethylene (PTFE) membrane, pleated to give high area in single open-end cartridges.

Emflon PFAW cartridges offer exceptionally high flow rates to ensure low installation, operating, and compressor energy costs. They provide an economical solution for large-scale fermenter air, general purpose venting, instrument air, and general duty air and gas service lines.

Features and Benefits

| Features | Benefits |

| Strongly hydrophobic 100 % PTFE membranes | Prevents wetting out in humid conditions, even after repeated use and steaming cycles, allowing excellent gas throughput |

| High area pleated, robust membrane construction | Enables extremely economical installations and compressor energy savings due to high flow rates and low pressure drops |

| Multi-cycle autoclave and in situ steam challenged | Enhanced steaming resistance |

| Validated for bacteria removal in air with aerosol challenge | Provides reliable and economical bioburden reduction in dry gas, protection of microbial cultures, protection of tank contents, and improved fermentation yields |

| Integrity testable by forward flow or pressure hold test | Ensures process security |

| 100% integrity tested prior to dispatch | Lot traceable with documented quality |

Materials of construction

| Filter Medium | PTFE |

| Support / Drainage | Polypropylene |

| Cage, Core, Fin End and End Cap | Polypropylene |

| Adaptor | Polypropylene with internal stainless steel reinforcing ring |

| O-ring Seal | Silicone Elastomer |

Food Contact Compliance

Please refer to the Pall website http://www.pall.com/foodandbev for a Declaration of Compliance to specific National Legislation and/or Regional Regulatory requirements for food contact use.Technical Information

Nominal Filter Area: 0.8 m 2 (8.6 ft2) per 254 mm (10") module

Typical Service Life1 under continuous operating conditions

| Continuous gas2 service | 12 months to 60 °C (140 °F) |

| Vent service | 6 months to 80 °C (176 °F) |

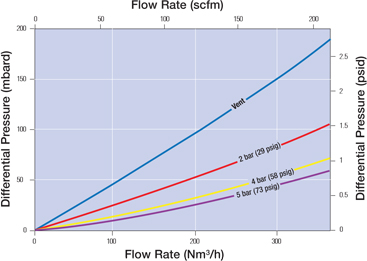

Typical Flow Rates3

Steaming

| Cumulative Steaming Time | Operating Temperature |

| 40 hours (1-hour cycles, forward) | 140 °C (284 °F) |

| 100 hours (1-hour cycles, forward) | 125 °C (257 °F) |

| Maximum Steaming Conditions | Steaming Temperature |

| 0.3 bard (4.3 psid) (forward) | 140 °C (284 °F) |

Removal Ratings

| Fluid | Performance |

| Gases | 0.3 micron particles in dry gas 4, aerosol removal of bacteria5 |

1 Emflon PFAW can be operated at higher temperatures for shorter periods. Please contact Pall for application details.

2 Air, nitrogen, or other compatible gases

3 Typical clean Δp per 254 mm (10") cartridge, air at 20 °C (68 °F). For gases other than air and for multi-round cartridge installations, please contact Pall for proper sizing.

4 By NaCl aerosol CNC particle analysis, average removal efficiency > 99.9%. Please contact Pall for details.

5 Passing an appropriate integrity test, provides sterile effluent when aerosol challenged with Brevundimonas diminuta at >107 cfu/254 mm (10") cartridge

Quality

- Cartridges produced in a controlled environment

- Manufactured according to ISO 9001:2008 certified Quality Management System

Filter Cartridges

This information is a guide to the part number structure and possible options. For availability of specific options and housing details, please contact Pall.

Part Number: AB [Table1] PFA [Table2] W H4

Example Part Number: AB1PFA7WH4Table 1: Nominal Length

| Code | Description |

| 05 | 127 mm (5") |

| 1 | 254 mm (10") |

| 2 | 508 mm (20") |

| 3 | 762 mm (30") |

Table 2: Adaptor

| Code | Description |

| 2* | SOE – single open end with flat closed end, 2 locking tabs and external 226 O-rings |

| 3 | SOE – single open end with flat closed end and external 222 o-rings |

| 7 | SOE - single open end with fin end, 2 locking tabs and external 226 O-rings |

| 8 | SOE - single open end with fin and external 222 O-rings |

| 28 | SOE - single open end with fin end, 3 locking tabs and external 222 o-rings |

*AB05 configurations only. For availability of additional adaptor configurations, please contact Pall.

We appreciate your review of this product. Please login to your account to leave a review.