Datasheets

Download:Water in hydraulic, lubrication, power transmission and insulating fluids adversely affects fluid performance and is a threat to system reliability.

Water contamination promotes corrosion and fluid system component wear, resulting in reduced component life and increased maintenance costs. It also degrades fluid properties, leading to reduced lubricity and load carrying ability, oil oxidation and the resultant formation of acids, and additive precipitation. The consequences are reduced fluid service life and increased fluid procurement and disposal costs.

The Pall HNP023 Series Oil purifier is designed for use with small to medium oil systems, particularly where high viscosity fluids are employed, and can effectively remove 40 liters of water per day from the oil*.

The Pall HNP fluid conditioning purifier uses vacuum dehydration to remove 100 % free water and as much as 90 % of dissolved water. It will also remove 100 % of free and entrained gases and up to 80 % dissolved gases.

Vacuum dehydration is the most effective method of water removal at minimum cost and ease of use. Unlike other methods it removes both free and dissolved water and cannot burn or otherwise significantly alter the properties of the oil.

Particulate contaminant removal is achieved using high performance rated (ß3(c) >2000) Athalon® filter elements.

In addition, a WS12 Series water sensor measures water content and temperature at the purifier inlet, allowing the purifier to operate only when the water content rises above a pre-determined level.

* Water removal rates are affected by the fluid viscosity, temperature, form of water (free or dissolved) and the amount of water present. Pall utilizes a well defined and repeatable test procedure that ensures thorough dispersion of the water in the test fluid initially and throughout the test. The water removal rate shown is for tests with ISO VG 32 mineral based turbine lube oil at 60 °C in the range of 2.6 % to 1.4 % water. The removal rates at higher water concentrations will be significantly higher.

Select the HNP023 oil purifier for:

- High performance water, gas and particulate removal

- Extension of fluid service life

- Minimized corrosion within systems

- Reduced fluid disposal

- Reduced operating costs

- Increased equipment reliability

- Simple automated operation

- Remote monitoring option

Removing free water is never enough!

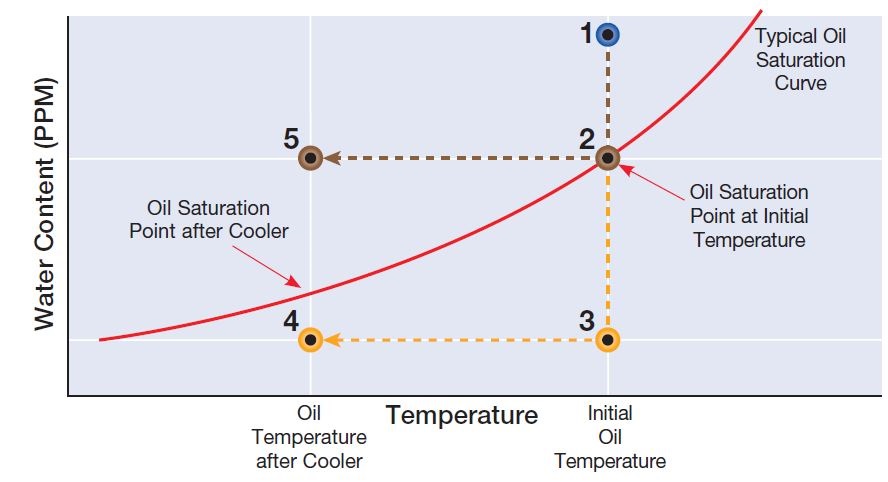

1. Initial water content is above saturation (free water).

1. Initial water content is above saturation (free water). 2. Maximum water removal capability of ‘free water removal’ devices (coalescers, centrifuges, etc.) is to the oil’s saturation point.

3. Water content achieved with vacuum dehydration is significantly below the oil’s saturation point.

4. Water content achieved with vacuum dehydration remains below the oil’s saturation point even after oil is cooled by the system heat exchanger. This prevents the formation of free water which is detrimental to fluid system components and the fluid.

5. If only free water is removed at initial temperature, when oil is cooled the amount of free water in the oil can increase significantly.

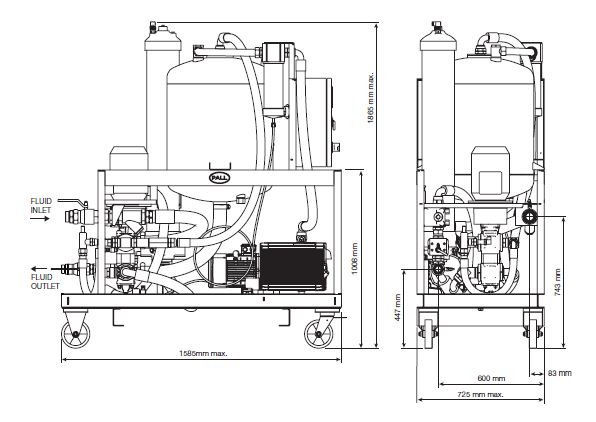

| Dimensions: | 725 mm x 1585 mm x 1865 mm (28.5 ” x 62.4 ” x 73.5 ”) |

| Dry mass: | 385 kg (849 lb) approx |

| Inlet connections: | 2 ” BSPP or 2 ” NPT |

| Outlet connections: | 1½ ” BSPP or 1½ ” NPT |

| Inlet pressure: | -0.4 bar g (-40kPag / -5.8 psi g) minimum 1.5 bar g (150kPag / 44 psi g) maximum |

| System back pressure: | 3.5 bar g (350 kPag / 50.8 psi g) maximum |

| Fluid operating temperature: | +10 ºC (50 °F) to +70 ºC (158 °F) |

| Fluid viscosity: | 700 cSt (3300 SUS) maximum |

| Operating vacuum: | -0.6 barg to -0.9 bar g (adjustable) (-60 kPag / -8.7 psi g to -90 kPag / -13.1 psi g) |

| Power supply: | See Table 1 |

| Total Motor power: | 5.5 kW @ 50 Hz, 3Ø 7.3 kW @ 60 Hz, 3Ø |

| Materials of Construction | |

| Base frame: | Epoxy painted carbon steel |

| Vacuum vessel: | 304 Stainless Steel |

| Fittings and fasteners: | Corrosion protected carbon steel |

| Control box: | Epoxy painted carbon steel |

| Hydraulic hoses and seals: | Fluorocarbon |

Note: Pall HNP076 series fluid conditioning purifiers comply with all applicable EC directives and bear the CE mark.

Purifier

P/N: HNP023 [Table 1/Code 1] [Table 1/Code 2] Z [Table 2] [Table 3] [Table 4] [Table 5]

Note: Z indicates fluorocarbon seals and AQP Elastomer Tube* hoses are standard. Other options are available; contact Pall.

Please select only from the following list of standard purifier options:

| HNP076S3ZCPENA HNP076S3ZCPENB HNP076S3ZCPENC HNP076S3ZCPEND HNP076S3ZCPDEA |

HNP076S3ZCPDEB HNP076S3ZCPDEC HNP076S3ZCPDED HNP076S3ZCPFRA HNP076S3ZCPITA |

HNP076S3ZCPITC HNP076R3ZCTENA HNP076R3ZCPENB HNP076R3ZCPRUB HNP076S3ZCPPLB |

Table 1 - Standard Voltage

| Code | Voltage |

| R | 380 VAC |

| S | 400 VAC |

Standard voltages only listed. Other voltages will be available on request - price and lead time will be provided on application.

Table 2 - Frequency Options

| Code | Frequency |

| 3 | 50 Hz, 3 phase |

Table 3 - Seal Type

| Code | Material |

| Z | Fluorocarbon |

Table 4 - Mounting Options

| Code | Mounting Type |

| C | Mobile (2 fixed and 2 swivel castors) |

Table 5 - Process Port Connection Options

| Code | 2” inlet / 1½” Outlet Connections |

| P | BSP ISO 228 threads |

Table 6 - Language Options

| Code | Language |

| DE | German |

| EN | English |

| RU | Russian |

| PL | Polish |

| FR | French |

| IT | Italian |

Table 7 - Optional Factory Fitted Kits

| Code | Kit |

| A | No optional kit(s) fitted |

| B | 5m electrical cable, socket and plug, in accordance with IEC 60309 to electrically connect the purifier |

| C | Gauge points, inlet and outlet pressure gauges and an inlet sight flow indicator to allow fluid condition and pressures to be monitored |

| D | Both kits B and C |

Optional inlet and outlet hose 5m P/N: HNP076HZ

Replacement Filter Element P/N: UE610 [Table 1] 40Z

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 1 - Element Rating

| Code | Bx(c) >2000 based on ISO16889 |

| AZ | 3 |

| AP | 5 |

| AN | 7 |

| AS | 12 |

| AT | 22 |

Replacement Air Breather

P/N: HC0293SEE5

We appreciate your review of this product. Please login to your account to leave a review.