Datasheets

Download:Athalon™ maximum-life filters deliver the highest level of sustained fluid system protection, across all applications, regardless of severity.

Featuring an industry leading BetaX(C)=2000* filter efficiency; the highest rated filter performance available today.

(* per ISO 16889)Features

- Patented Ultipleat (laid-over pleat) filter medium pack

- Pall Stress-Resistant Technology (SRT) Media

- Coreless filter element configuration

- Low clean differential pressure for low energy operation

Notes and Specifications Filter Housing

- Flows to 835 L/min (220 US

gpm ) - Pressures to 28 bar (400 psi)

- Port Size 2” and 2½”

- Rated Fatigue Pressure:

0-23 bar (330 psi) per NFPA T2.06.01R2-2001 CAT C/90/*(1 million cycles), verified by testing at 0-27 bar (392 psi) for 1 million cycles. - Filter Element Burst Pressure:

10 bard (150 psid) - Fluid Compatibility:

Compatible with all petroleum oils and most water glycols, water-oil emulsions, and synthetic hydraulic and lubrication fluids - Temperature Range:

Fluorocarbon Seals: -29 °C to 120 °C (-20 °F to 248 °F) 60 °C (140 °F) maximum in HWCF orwater glycol fluids - Bypass Valve Setting:

1.7 bard (25 psid) or

4.5 bard (65 psid) - Indicator Pressure Setting:

1.1 bard (16 psid) or

3.5 bard (50 psid) - Materials of Construction:

Head and tube: Aluminum

Cover: Steel/cast iron - Filter Element:

Inorganic fibers impregnated and bonded with epoxy resins. Polymer endcaps. Anti-static media design

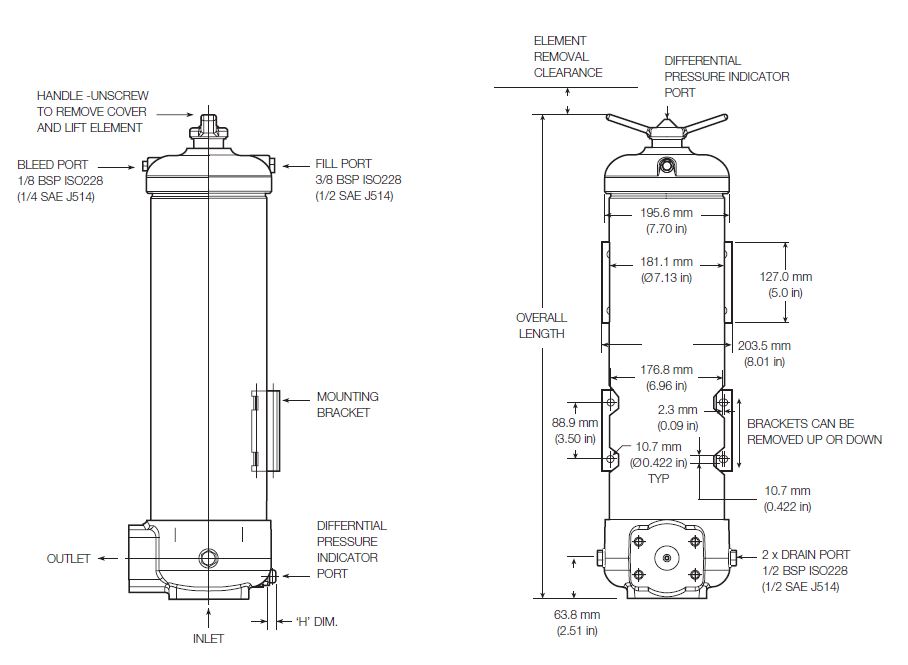

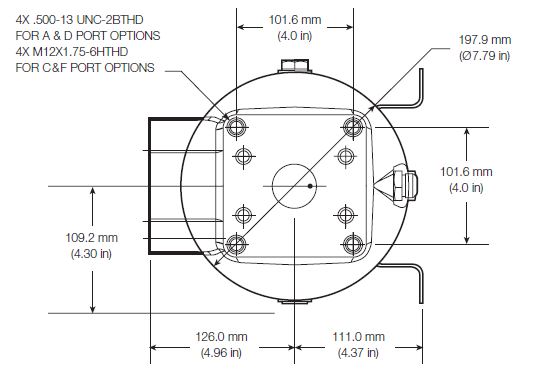

Dimensional Drawings

Dimensions in mm (inches)

The equipment has been assessed in accordance with the guidelines laid down in The European Pressure Directive 97/23/EC and has been classified within Sound Engineering Practice S.E.P. Suitable for use with Group 1 and 2 fluids only. Consult Sales for other fluid gas group suitability.

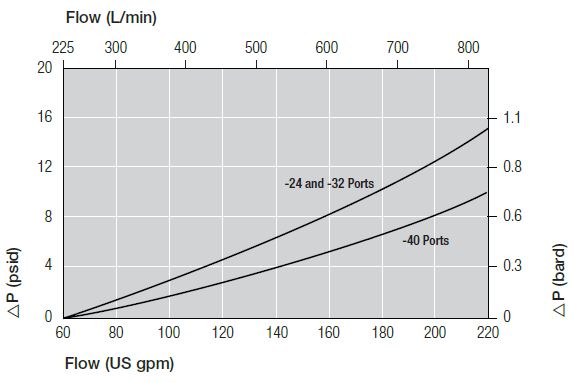

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G.

Housing pressure drop is directly proportional to specific gravity.

- Keeps fluids the cleanest, longest, for the greatest value

- Provides consistent, reliable, protection of system components over the

full service life of the filter element - Rapidly achieves and sustains required fluid system cleanliness

- Delivers maximum filter capacity in the smallest footprint

- Prevents electrostatic discharge from damaging your filter and degrading your fluid

Element Pressure Drop

610 Series Filter Elements – bard/1000 L/min (psid/US

| Length Code | AZ | AP | AN | AS | AT |

| 20 | 1.31 (0.072) | 0.56 (0.030) | 0.43 (0.023) | 0.31 (0.017) | 0.19 (0.011) |

| 40 | 0.70 (0.038) | 0.30 (0.016) | 0.23 (0.013) | 0.17 (0.009) | 0.10 (0.006) |

Sample ΔP calculation

UR6 19 Series 40" length housing with C32 (2" BSP) threaded ports using AN grade media. Operating conditions 500 L/min flow rate using a hydraulic fluid of 50 cSt and specific gravity (s.g.) 1.2.Total Filter ΔP

= ΔP housing + ΔP element

= (0.45 x 1.2/0.9) bard (housing)

+ ((600 x 0.23/1000) x 50/32 x 1.2/0.9) bard (element)

= 0.6 (housing) + 0.29 bard (element)

= 0.89 bard (9.3 psid)

Section 1 Housing P/N: UR 619 C [Table A] [Table 4] 9

Note: Pall Athalon filter housings are supplied without filter elements or warning devices fitted. Never operate the filter unless a filter element is fitted and all warning device ports are sealed.

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall. Housing P/N designates indicator port fitted with a plastic shipping plug.

| Table A |

| Port & Length Options |

| Tables 1, 2 and 3 |

| CA3220Z |

| CA3240Z |

| CC3220Z |

| CC3240Z |

| CD3220Z |

| CD3240Z |

| CD4020Z |

| CD4040Z |

| CF3220Z |

| CF3240Z |

| CF4020Z |

| CF4040Z |

Table 1: Housing Port Options

| Code | Port Style |

| A | SAE J1926 straight thread |

| C | BSP ISO 228 threads |

| D | Flange J518C code 61 |

| F | ISO 6162 split flange |

Table 2: Port Size

| Code | Port Style |

| 32 | 2” nominal |

| 40 | 2 ½” nominal |

Table 3: Housing Length and Seal Options

| Code | |

| 20Z | 20” nominal length, fluorocarbon seals |

| 40Z | 40” nominal length, fluorocarbon seals |

Table 4: Housing Bypass Valve Options

| Code | Bypass Valve and Service Type |

| A | 1.7 bard (25 psid) bypass valve, cover service |

| G | 4.5 bard (65 psid) bypass valve, cover service |

| N | No bypass valve |

Seal Kit P/N: UR619SKZ

*Other seal material options are available; Contact Pall.

Section 2 Element P/N: UE 610[Table 5] [Table 3]

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 5: Filter Element Options

| Code | ßx(c) ≥2000 based on ISO 16889 | CST Rating* |

| AZ | 3 | 07/04/01 |

| AP | 5 | 11/08/03 |

| AN | 7 | 13/09/04 |

| AS | 12 | 15/11/06 |

| AT | 25 | 16/14/08 |

* CST: Cyclic Stabilization Test to determine filter rating under stress conditions, based on SAE ARP4205

Section 3

(At least one Differential Pressure Indicator or ‘B’ type blanking plug must be ordered)

Differential Pressure Indicator P/N: RC [Table 6] Z [Table 7] Z [Table 8]

Note: If no differential pressure indicator is selected, ‘B’ type blanking plug (P/N HC9000A104Z) must be ordered separately and fitted to replace the plastic shipping plug.

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 6: Indicator Options

| Code | Brass Option indicator |

| A218M | |

| A218R | with Red and Green LED indicators |

| A219D | Visual indicator |

| Code | Stainless Steel indicator |

| 778N | Visual filter with |

| 861C* | |

| 771B | |

Other setting options are available; contact Pall.

* Requires YM suffix after SS code from Table 7.

Table 7: Indicator Pressue Setting Option

| Code | Valve |

| 084 | For ‘A’ Valve Option - Housings (1.1 bard - 16 psid) |

| 091 | For ‘G’ and ‘N’ Valve Options - Housings (3.5 bard - 50 psid) |

Other setting options are available; contact Pall.

Table 8: Differential Pressure Indicator Material

| Code | Description |

| Omit | If Brass indicator is chosen in Table 6 |

| SS | If Stainless Steel Indicator is chosen in Table 6. Note: SS indicator is recommended for |

Other setting options are available; contact Pall.

We appreciate your review of this product. Please login to your account to leave a review.