Datasheets

Download:Features

- Flows to 760 L/min (200 US gpm)

- Pressures to 10 bard (150 psid)

- Port size 11⁄2", 2" and 21⁄2"

- Unique Ultipleat (laid-over pleat) filter medium pack

- Coreless, cageless element configuration

- Pall Stress-Resistant Technology (SRT) Media

- In-to-out filter element flow path

The UT319 Series is a Preferred Product Line utilizing Stress-Resistant Technology. Please See Ordering Information for available options

All replacement filter elements, differential pressure indicators and sealkits remain available for this series. See ‘Ordering Information’ tab above for details of spares.

Filter Housing

- Maximum Allowable Working Pressure:

10 bard (150 psid) - Fluid Compatibility:

Compatible with all petroleum oils, water glycols, water-oil emulsions and most synthetic hydraulic and lubrication fluids - Temperature Range:

Fluorocarbon Seals: -29 °C to 120 °C (-20 °F to 250 °F) 60 °C (140 °F) maximum in HWCF or water glycol fluids - Materials of Construction:

Die cast aluminum alloy head, and cover, steel shell. Use YR85 option for cast iron head and cover

Filter Element

- Filter Element Burst Pressure:

10 bard (150 psid) - Ultipleat SRT Element Construction:

Inorganic fibers impregnated and bonded with epoxy resins. Polymer endcaps. Anti-static media design

The equipment has been assessed in accordance with the guidelines laid down in The European Pressure Directive 97/23/EC and has been classified within Sound Engineering Practice S.E.P. Suitable for use with Group 2 fluids only. Consult Sales for other fluid gas group suitability.

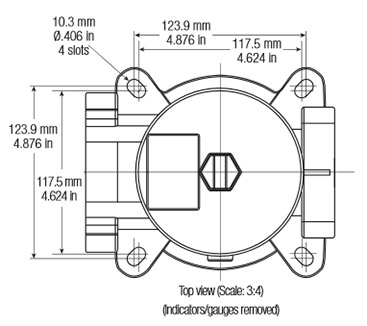

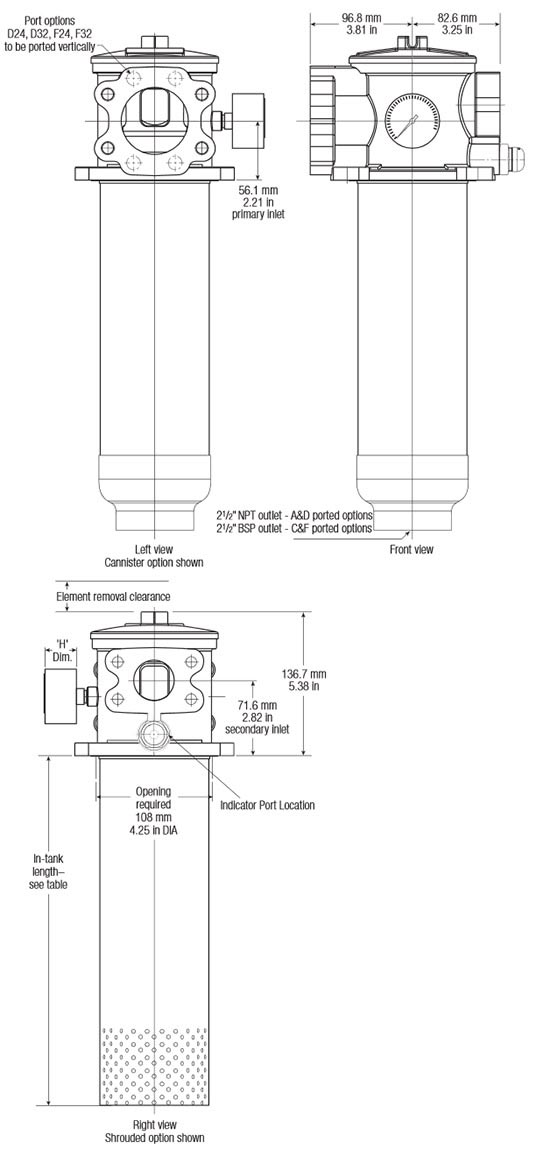

| Length Code | In-tank Length mm (in.) | Element Removal Clearance mm (in.) | |

| 'C' Option | 'S' Option | ||

| 08 | 337 (13.25) | 295 (11.62) | 229 (9) |

| 13 | 464 (18.25) | 422 (16.62) | 361 (14.2) |

| 20 | 641 (25.25) | 600 (23.62) | 533 (21) |

| 40 | 1149 (45.25) | 1108 (43.62) | 1041 (41) |

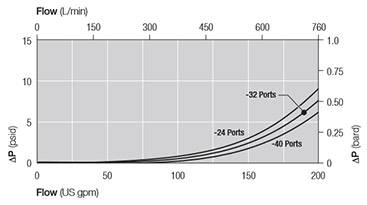

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G.

Housing pressure drop is directly proportional to specific gravity.

Element Pressure Drop

Multiply actual flow rate times factor in table below to determine pressure drop with fluid at 32 cSt (150 SUS), 0.9 S.G. Correct for other fluids by multiplying new viscosity in cSt/32 (SUS/150) x new S.G./0.9. Note: factors are per 1000 L/min and per 1 US gpm.319 Series Filter Elements — bard/1000 L/min (psid/US gpm)

| Length Code | AZ | AP | AN | AS | AT |

| 08 | 5.52 (0.302) | 2.30 (0.126) | 1.82 (0.100) | 1.32 (0.072) | 0.82 (0.045) |

| 13 | 3.31 (0.182) | 1.38 (0.076) | 1.09 (0.060) | 0.79 (0.043) | 0.49 (0.027) |

| 20 | 2.18 (0.120) | 0.91 (0.050) | 0.72 (0.040) | 0.52 (0.029) | 0.33 (0.018) |

| 40 | 1.10 (0.060) | 0.46 (0.025) | 0.36 (0.020) | 0.26 (0.014) | 0.16 (0.009) |

Sample ΔP calculation

UT319 Series 13" length housing with F24 (1 1/2"SAE) split flange ports using AN grade media. Operating conditions 200 L/min flow rate using a hydraulic fluid of 50 cSt and specific gravity (s.g.) 1.2.Total Filter ΔP

= ΔP housing + ΔP element

= (0.05 x 1.2/0.9) bard (housing

+ ((200 x 1.09/1000) x 50/32 x 1.2/0.9) bard (element)

= 0.07 bard (housing) + 0.45 bard (element)

= 0.52 bard (7.6 psid)

Housings, Vessels, or Assemblies

Please select only from the following list of standard filter housing options.

The specification of each filter housing part number is outlined in the tables below.

Seal Kit P/N: UT 319 SKZ

Gauge/Switch P/N: See Table 1

Note: Use 1.1 bar rating for A valve options

Available UT319 Series Options

| UT319A24 08ZASBBB UT319C24 08ZASBBB UT319D24 08ZASBBB UT319F24 08ZASBBB UT319A24 13ZASBBB UT319C24 13ZASBBB UT319D24 13ZASBBB UT319F24 13ZASBBB UT319D32 13ZASBBB UT319F32 13ZASBBB UT319D32 20ZASBBB UT319F32 20ZASBBB UT319D40 20ZASBBB UT319D40 40ZASBBB | UT319F40 20ZASBBB UT319F40 40ZASBBB UT319A24 08ZGSBBB UT319C24 08ZGSBBB UT319D24 08ZGSBBB UT319F24 08ZGSBBB UT319A24 13ZGSBBB UT319C24 13ZGSBBB UT319D24 13ZGSBBB UT319F24 13ZGSBBB UT319D32 13ZGSBBB UT319F32 13ZGSBBB UT319D32 20ZGSBBB UT319F32 20ZGSBBB | UT319D40 20ZGSBBB UT319D40 40ZGSBBB UT319F40 20ZGSBBB UT319F40 40ZGSBBB |

The specification of each filter housing part number is outlined in the tables below.

Section 1

Housing P/N: UT 319 [Table 1] ++ [Table 2] Z [Table 3] [Table 4] BN BSeal Kit P/N: UT 319 SKZ

Note: Pall Ultipleat SRT filter housings are supplied without filter elements or warning devices fitted. Never operate the filter unless a filter element is fitted and all warning device ports are sealed.

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall. ‘BNB’ at the end of the Housing P/N designates 1 gauge port, and one indicator port, both fitted with plugs.

*Other seal material options are available; Contact Pall.

Table 1: Housing Port Options

| Code | Port |

| A24 | 11⁄2" SAE J514 straight thread |

| D24 | 11⁄2" Flange J518C code 61 with 1⁄2"-13 UNC holding bolts |

| D32 | 2" Flange J518C code 61 with 1⁄2"-13 UNC holding bolts |

| D40 | 21⁄2" Flange J518C code 61 with 1⁄2"-13 UNC holding bolts |

| C24 | 11⁄2" BSP ISO 228 threads |

| F24 | 11⁄2" ISO 6162 split flange with M12 x 1.75 holding bolts |

| F32 | 2" ISO 6162 split flange with M12 x 1.75 holding bolts |

| F40 | 21⁄2" ISO 6162 split flange with M12 x 1.75 holding bolts |

Table 2: Housing Length Options

| Code | Length (in)* |

| 08 | 8 |

| 13 | 13 |

| 20 | 20 |

| 40 | 40 |

* Nominal length

Table 3: Bypass Valve Options

| Code | Valve |

| A | 1.7 bard (25 psid) with shroud |

| G | 4.5 bard (65 psid) with shroud |

Table 4: Secondary Port Options

| Code | Port |

| N | No secondary port |

| S | 11⁄4" port (same style as primary port) |

Section 2

Element P/N: UE 319 [Table 1] [Table 2] ZNote: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 1: Filter Element Options

| Code | ßx(c) ≥1000 based on ISO 16889 | CST Rating* |

| AZ | 3 | 08/04/01 |

| AP | 5 | 12/07/02 |

| AN | 7 | 15/11/04 |

| AS | 12 | 16/13/04 |

| AT | 22 | 17/15/08 |

* CST: Cyclic Stabilization Test to determine filter rating under stress conditions, based on SAE ARP4205

Table 2: Filter Element Length Options

| Code | Length (in)* |

| 08 | 8 |

| 13 | 13 |

| 20 | 20 |

| 40 | 40 |

* Nominal length

Section 3

Differential Pressure Indicator P/N: RC [Table 2] [Table 3] Z [Table 4]Gauge/Switch P/N: See Table 1

Note: Z indicates fluorocarbon seals are standard. Other options are available; contact Pall.

Table 1: Gauge / Switch Options

| Part No | Rating | Indicator | ‘H’ Dim |

| 1373772 | - | 'B' option 1/8" blanking plug | 3mm (0.1 in.) |

| 9004D370-11 | 0-10 bard (150 psid) | 'A' type Pressure Gauge | 32mm (1.3 in.) |

| 9004D370-34 | 0-10 bard (150 psid) | 'G' type Pressure Gauge | 32mm (1.3 in.) |

| HC0379-11 | 1.1 bard (16 psid) | Electrical absolute pressure switch 24VDCElectrical absolute pressure switch 220VAC with Hirschmann connector | 54mm (2.1 in.) |

| HCA132-35 | 3.5 bard (50 psid) | ||

| HC0618-11 | 1.1 bard (16 psid) | Electrical absolute pressure switch 220VAC with Hirschmann connector | 83mm (3.25 in.) |

| HC0618-35 | 3.5 bard (50 psid) | ||

| HC0380-11 | 1.1 bard (16 psid) | Electrical absolute pressure switch 220VAC with 3 (15") flying leads | 55mm (2.2 in.) |

| HC0380-35 | 3.5 bard (50 psid) | ||

Note: Use 1.1 bar rating for A valve options

Use 3.5 bar rating for G, 3 and 7 valve options

Table 2: Differential Pressure Indicator Options

| Code | Indicator | ‘H’ Dim. |

| 778NZ | ‘P’ type Visual indicator with thermal lockout | 21mm (0.83 in) |

| 860MZ | ‘D’ type Visual indicator with no thermal lockout | 21mm (0.83 in) |

| 861CZ | ‘L’ type Electrical switch (SPDT) with 6" lead | 38mm (1.50 in) |

| 861CZ | ‘M’ type Electrical switch (SPDT) with DIN43650 connector and matching cap | 78mm (3.07 in) |

* Other options available on application.

Table 3: Indicator Pressure Setting Options*

| Code | Pressure Setting |

| 084 | For ‘A’ Valve Option Housings (1.1 bard - 16 psid) |

| 091 | For ‘G’, ‘3’ and ‘7’ Valve Option Housings (3.5 bard - 50 psid) |

* Other setting options are available; contact Pall.

Table 4: 'M' Type Indicator Code*

| Code | Option |

| YM | 'M' option |

* Use only if 'M' Indicator is selected from Table 8

We appreciate your review of this product. Please login to your account to leave a review.