Datasheets

Download:Athalon® Multi-Element Fabricated Vessels Port Size 3”, 4”, 6” and 8”

Athalon® maximum-life filters deliver the highest level of sustained fluid system protection, across all applications, regardless of severity. Featuring an industry leading BetaX(C)≥2000* filter efficiency; the highest rated filter performance available today. (* per ISO 16889)

Notes and Specifications Filter Housing

- Flows to: 1500 L/min (400 US gpm), AFV03 Series 2500 L/min (660 US gpm), AFV07 Series 3500 L/min (925 US gpm), AFV10 Series 5000 L/min (1320 US gpm), AFV15 Series

- Port size 3”, 4”, 6” and 8”

-

Working Pressure Design:

15 bar (217 psi). -

Fluid Compatibility:

Compatible with all petroleum oils, water glycols, water-oil emulsions and most synthetic hydraulic and lubrication fluids -

Temperature Range:

Nitrile Seals -43°C to 80°C (-45°F to 175°F) -

Materials of Construction:

Carbon steel housing, nozzlesand flanges Carbon steel transfer valve body with S/S valve ball -

Finish:

Interior finish: grit blast then coated with rust preventative Exterior finish: grit blast then coated with primer and paint

Filter Element

- Filter Element Burst Pressure:

10 bard(150 psid) - Athalon Element Construction:

Inorganic fibers impregnated and bonded with epoxy resins. Polymer endcaps. Anti-static media design

Element Pressure Drop

Multiply actual flow rate times factor in

| Length Code | AZ | AP | AN | AS | AT |

| 40 | 1.10 (0.060) | 0.46 (0.025) | 0.36 (0.020) | 0.26 (0.014) | 0.16 (0.009) |

Sample ΔP calculation

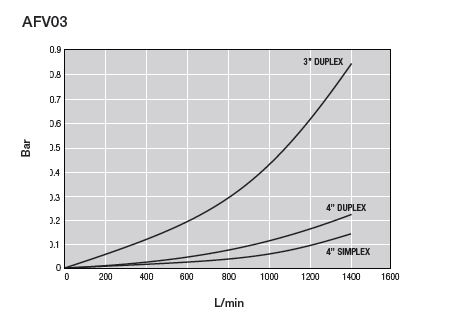

AFV03 Duplex Series with 4"

Total Filter ΔP

100 cSt, S.G. of 0.88.

= (0.04 x 0.88/0.9) bard (housing)

(500/3 x 0.26/1000 x 100/32 x 0.88/0.9) bard (element)

= 0.17 bard (2.47 psid)

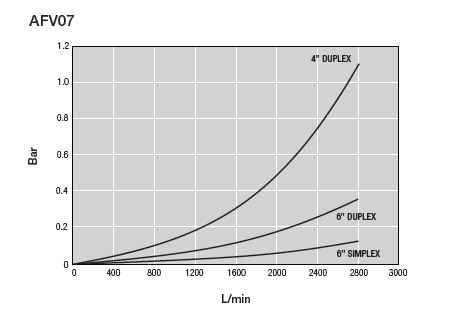

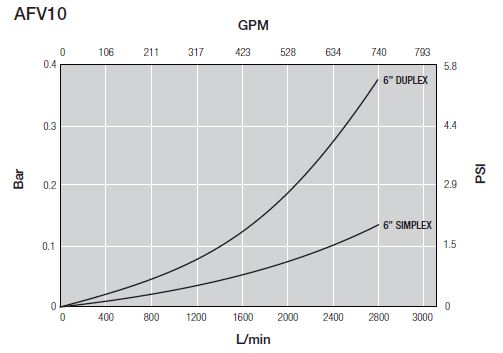

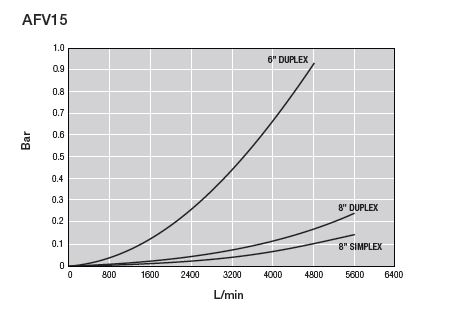

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G.

Housing pressure drop is directly proportional to specific gravity.

Fabricated Vessels are designed and manufactured in compliance with ASME and PED requirements. Consult Pall for any further information.

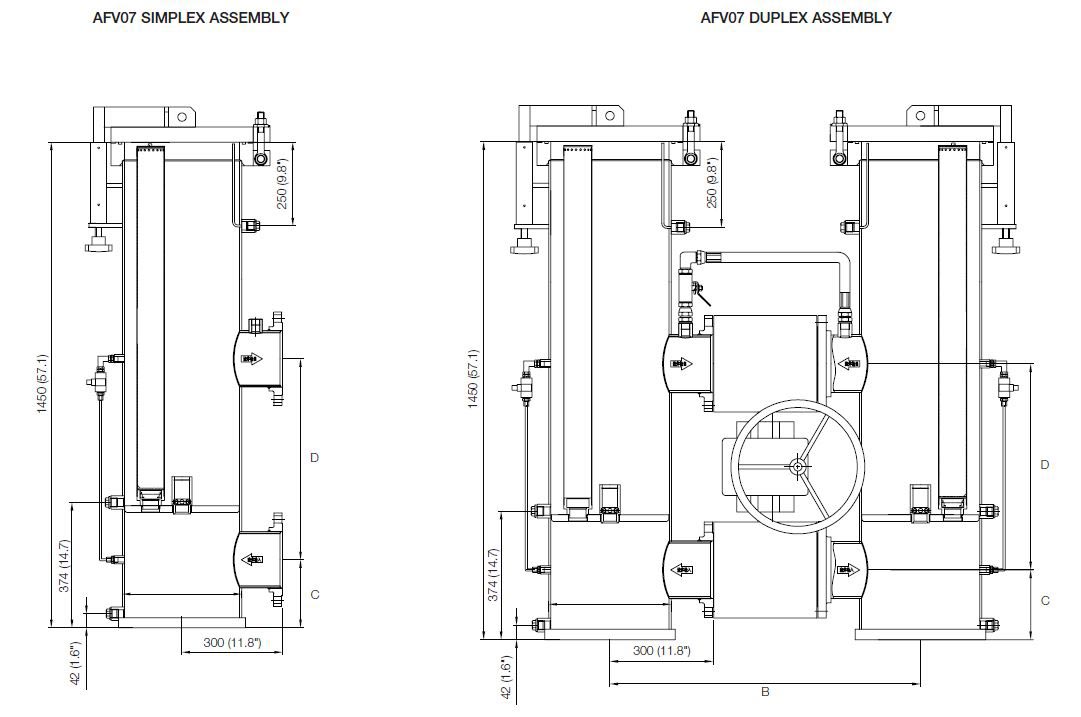

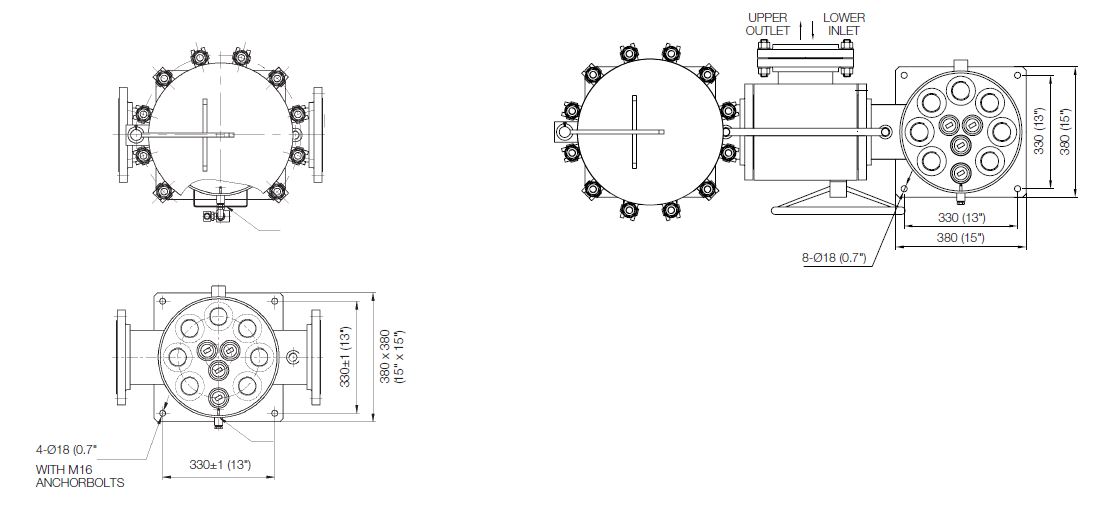

Dimensional Drawings

Dimensions in mm (inches)

The equipment has been assessed in accordance with the guidelines laid down in The European Pressure Directive 97/23/EC and has been classified within Sound Engineering Practice S.E.P. Suitable for use with Group 1 and 2 fluids only. Consult Sales for other fluid gas group suitability.

Technical Specification

AFV03/05/07/10/15 series Filters

AFV03 Series

| 'Nozzle Size | 'A' Simplex | 'B' Duplex | 'C' | 'D' | 'E' | 'F' | 'G' | |

| mm | DIN 75 | 254 | 644 | 203 | 290 | 273 | 175 | 1200 |

| in | 3 | 10.0 | 25.4 | 8.0 | 11.4 | 10.7 | 6.9 | 47.2 |

| mm | DIN 100 | 254 | 664 | 203 | 350 | 273 | 185 | 1200 |

| in | 4 | 10.0 | 26.1 | 8.0 | 13.8 | 10.7 | 7.3 | 47.2 |

AFV07 Series

| 'Nozzle Size | 'A' Simplex | 'B' Duplex | 'C' | 'D' | 'E' | 'F' | 'G' | |

| mm | DIN 100 | 300 | 756 | 203 | 350 | 356 | 185 | 1200 |

| in | 4 | 11.8 | 29.8 | 8.0 | 13.8 | 14.0 | 7.3 | 47.2 |

| mm | DIN 150 | 300 | 906 | 203 | 600 | 356 | 215 | 1200 |

| in | 6 | 11.8 | 35.7 | 8.0 | 23.6 | 14.0 | 8.5 | 47.2 |

AFV10 Series

| 'Nozzle Size | 'A' Simplex | 'B' Duplex | 'C' | 'D' | 'E' | 'F' | 'G' | |

| mm | DIN 150 | 357 | 1020 | 203 | 203 | 406 | 215 | 1200 |

| in | 6 | 14.1 | 40.2 | 8.0 | 8.0 | 16.0 | 8.5 | 47.2 |

AFV15 Series

| 'Nozzle Size | 'A' Simplex | 'B' Duplex | 'C' | 'D' | 'E' | 'F' | 'G' | |

| mm | DIN 150 | 450 | 1206 | 250 | 600 | 508 | 215 | 1200 |

| in | 6 | 17.7 | 47.5 | 9.8 | 23.6 | 20.0 | 8.5 | 47.2 |

| mm | DIN 200 | 450 | 1576 | 250 | 860 | 508 | 335 | 1200 |

| in | 8 | 17.7 | 62.0 | 9.8 | 33.9 | 20.0 | 13.2 | 47.2 |

For new installations, select one complete part number from each section below

Section 1

Note: Pall Athalon filter housings are supplied without filter elements or warning devices fitted. Never operate the filter unless a filter element is fitted and all warning device ports are sealed.

Table 1

| Code | Description |

| 03TJ04 | 3 element Simplex with 4" ANSI class 150# flanges |

| 03DJ03 | 3 element Duplex with 3" ANSI class 150# flanges |

| 03DJ04 | 3 element Duplex with 4" ANSI class 150# flanges |

| 07TJ06 | 7 element Simplex with 6" ANSI class 150# flanges |

| 07DJ04 | 7 element Duplex with 4" ANSI class 150# flanges |

| 07DJ06 | 7 element Duplex with 6" ANSI class 150# flanges |

| 03TJ04 | 3 element Simplex with 4" ANSI class 150# flanges |

| 03DJ03 | 3 element Duplex with 3" ANSI class 150# flanges |

Table 2

| Code | Internal Bypass Valve |

| B | 3.4 bard - 50 psid |

| N | Without Bypass Valve |

Table 3

| Code | Design Code |

| CN | GB150 |

| CE | Conforms to EU Pressure Directive |

| AS | ASME, Code VIII Stamp |

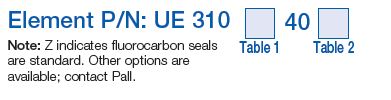

Section 2

Table 1

| Code | ßx(c) ≥2000 based on ISO 16889 | CST Rating* |

| AZ | 3 | 07/04/01 |

| AP | 5 | 11/08/03 |

| AN | 7 | 13/09/04 |

| AS | 12 | 15/11/06 |

| AT | 22 | 16/14/08 |

Table 2

| Code | Seal Option |

| H | Nitrile |

| Z | |

Section 3

Differential Pressure Indicator

All Pall standard visual indicators or electrical switches can be fitted on these vessels. Contact Pall for any further information.

We appreciate your review of this product. Please login to your account to leave a review.