Datasheets

Download:- Single cartridge housing accepts AB style, single open end filter elements

- All wetted parts are made of stainless steel construction

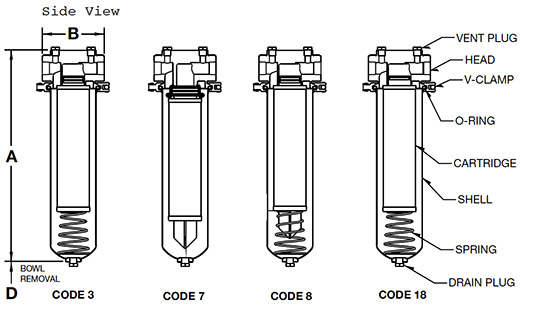

- Accepts 1 in. (2.54 cm), 5 in. (12.7 cm), 10 in. (25.4 cm), 20 in. (50.8 cm) or 30 in. (76.2 cm) Code 3, Code 7, Code 8 or Code 18 filter cartridges

- In-line inlet and outlet connections for easy installation

- Quick opening t-handle v-band clamp facilitates filter change-out

- Wide choice of inlet/outlet sizes and o-ring seal options

- Passivated for purity

For detailed information about this product, please refer to the data sheet. (To download this data sheet, select Download PDF from the menu above.)

Housing Specifications

Design ratings1

260 psig (17.9 bar) @ 100°F (40°C)200 psig (13.8 bar) @ 300°F (150°C)

NOTE: Above ratings apply to housing only. Cartridge and housing O-ring selection may impose different and narrower limitations. If Canadian registration is required refer to IOLC Data Sheet PIIOLCEN for CRN approved filter housings.

Materials of construction

Head: 316L stainless steelBowl: 316 stainless steel

Connections

Inlet/Outlet: 3⁄4" NPT, 1" NPT, 3⁄4" BSPT, 1" BSPTFlange Option: 150 lb. ANSI raised face flanges for 1 in. IOL housings

Vent/Drain: 1⁄4" NPT, BSPT or BSPP

Shell O-rings

FEP encapsulated fluorocarbon elastomer, silicone elastomer, fluorocarbon elastomer, nitrile, ethylene propylene, ethylene propylene for steam serviceBracket option

Stainless steel brackets are available as a standard option.1 Fully vacuum rated.

Housing Differential Pressure vs. Liquid Flow Rate

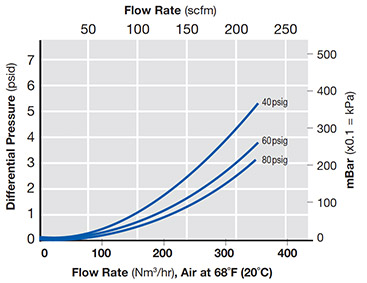

Housing Differential Pressure vs. Air Flow Rate

For liquids other than water, multiply differential pressure by specific gravity.

| Model | Flow2 Rate (gpm / lpm) | Dimensions | Volume | Weight Empty | ||||

| A | B | C | D | Threaded Nozzle | Flanged Nozzle | |||

| in./mm | in./mm | in./mm | in./mm | Gal/L | lbs/Kg | lbs/Kg | ||

| IOL301 | 1/3.78 | 5.81/147.57 | 4.81/122 | 9.81/250 | 2/50.8 | .04 /.15 | 4.5/2 | ——— |

| IOL305 | 5/19 | 7.8/198 | 4.81/122 | 9.81/250 | 4/102 | 0.11 /0.4 | 5.1/2.32 | 11.9/5.4 |

| IOL31 | 10/38 | 16.5/419 | 4.81/122 | 9.81/250 | 12.63/321 | 0.42/1.6 | 5.95/2.7 | 12.8/5.8 |

| IOL32 | 20/76 | 26.25/667 | 4.81/122 | 9.81/250 | 22.5/572 | 0.82/3.1 | 6.92/3.14 | 13.7/6.2 |

| IOL33 | 30/114 | 36.13/918 | 4.81/122 | 9.81/250 | 32.38/822 | 1.22/4.6 | 7.89/3.58 | 14.7/6.7 |

| IOL701 | 1/3.78 | 5.81/147.57 | 4.81/122 | 9.81/250 | 2/50.8 | .04 /.15 | 4.5/2 | ——— |

| IOL705 | 5/19 | 7.8/198 | 4.81/122 | 9.81/250 | 4/102 | 0.11/0.4 | 5.1/2.32 | 11.9/5.4 |

| IOL71 | 10/38 | 16.5/419 | 4.81/122 | 9.81/250 | 12.63/321 | 0.42/1.6 | 5.95/2.7 | 12.8/5.8 |

| IOL72 | 20/76 | 26.25/667 | 4.81/122 | 9.81/250 | 22.5/572 | 0.82/3.1 | 6.92/3.14 | 13.7/6.2 |

| IOL73 | 30/114 | 36.13/918 | 4.81/122 | 9.81/250 | 32.38/822 | 1.22/4.6 | 7.89/3.58 | 14.7/6.7 |

| IOL801 | 1/3.78 | 5.81/147.57 | 4.81/122 | 9.81/250 | 2/50.8 | .04 /.15 | 4.5/2 | ——— |

| IOL805 | 5/19 | 7.8/198 | 4.81/122 | 9.81/250 | 4/102 | 0.11/0.4 | 5.1/2.32 | 11.9/5.4 |

| IOL81 | 10/38 | 16.5/419 | 4.81/122 | 9.81/250 | 12.63/321 | 0.42/1.6 | 5.95/2.7 | 12.8/5.8 |

| IOL82 | 20/76 | 26.25/667 | 4.81/122 | 9.81/250 | 22.5/572 | 0.82/3.1 | 6.92/3.14 | 13.7/6.2 |

| IOL83 | 30/114 | 36.13/918 | 4.81/122 | 9.81/250 | 32.38/822 | 1.22/4.6 | 7.89/3.58 | 14.7/6.7 |

| IOL1801 | 1/3.78 | 5.81/147.57 | 4.81/122 | 9.81/250 | 2/50.8 | .04 /.15 | 4.5/2 | ——— |

| IOL1805 | 5/19 | 7.8/198 | 4.81/122 | 9.81/250 | 4/102 | 0.11/0.4 | 5.1/2.32 | 11.9/5.4 |

| IOL181 | 10/38 | 16.5/419 | 4.81/122 | 9.81/250 | 12.63/321 | 0.42/1.6 | 5.95/2.7 | 12.8/5.8 |

| IOL182 | 20/76 | 26.25/667 | 4.81/122 | 9.81/250 | 22.5/572 | 0.82/3.1 | 6.92/3.14 | 13.7/6.2 |

| IOL183 | 30/114 | 36.13/918 | 4.81/122 | 9.81/250 | 32.38/822 | 1.22/4.6 | 7.89/3.58 | 14.7/6.7 |

Housings, Vessels, or Assemblies

Pall Part Number = IOL [1] [2] G [3] [4]

Table 1

| Code | Cartridge style |

| 3 | Code 3 |

| 7 | Code 7 |

| 8 | Code 8 |

| 18 | Code 18 |

Table 2

| Code | Bowl length | ||

| 01 | 1 in (available in Code 3 only, with N16 or B16 option) | 1 | 10 in. |

| 2 | 20 in. | ||

| 05 | 5 in. | 3 | 30 in. |

Table 3

| Code | Inlet/outlet and vent/drain size |

| N12 | 3⁄4" NPT/1⁄4" NPT |

| N16 | 1" NPT/1⁄4" NPT |

| B12 | 3/4" BSPT/1⁄4" BSPT |

| B16 | 1" BSPT/1⁄4" BSPT |

| B17 | 1" ANSI flange /1⁄4" BSPT |

| N17 | 1" ANSI flange /1⁄4" NPT |

| P17 | 1" ANSI flange /1⁄4" BSPP |

| P19 | 1" BSPP /1⁄4" BSPP |

| B35 | 1" BS4504 flange /1⁄4" BSPT |

| P35 | 1" BS4504 flange /1⁄4" BSPP |

Table 4

| Code | Seal materials |

| H | Fluorocarbon elastomer |

| H1 | FEP encapsulated fluorocarbon elastomer |

| H4 | Silicone |

| H13 | Nitrile |

| J | Ethylene propylene |

| J7 | Ethylene propylene for steam service |

We appreciate your review of this product. Please login to your account to leave a review.