Datasheets

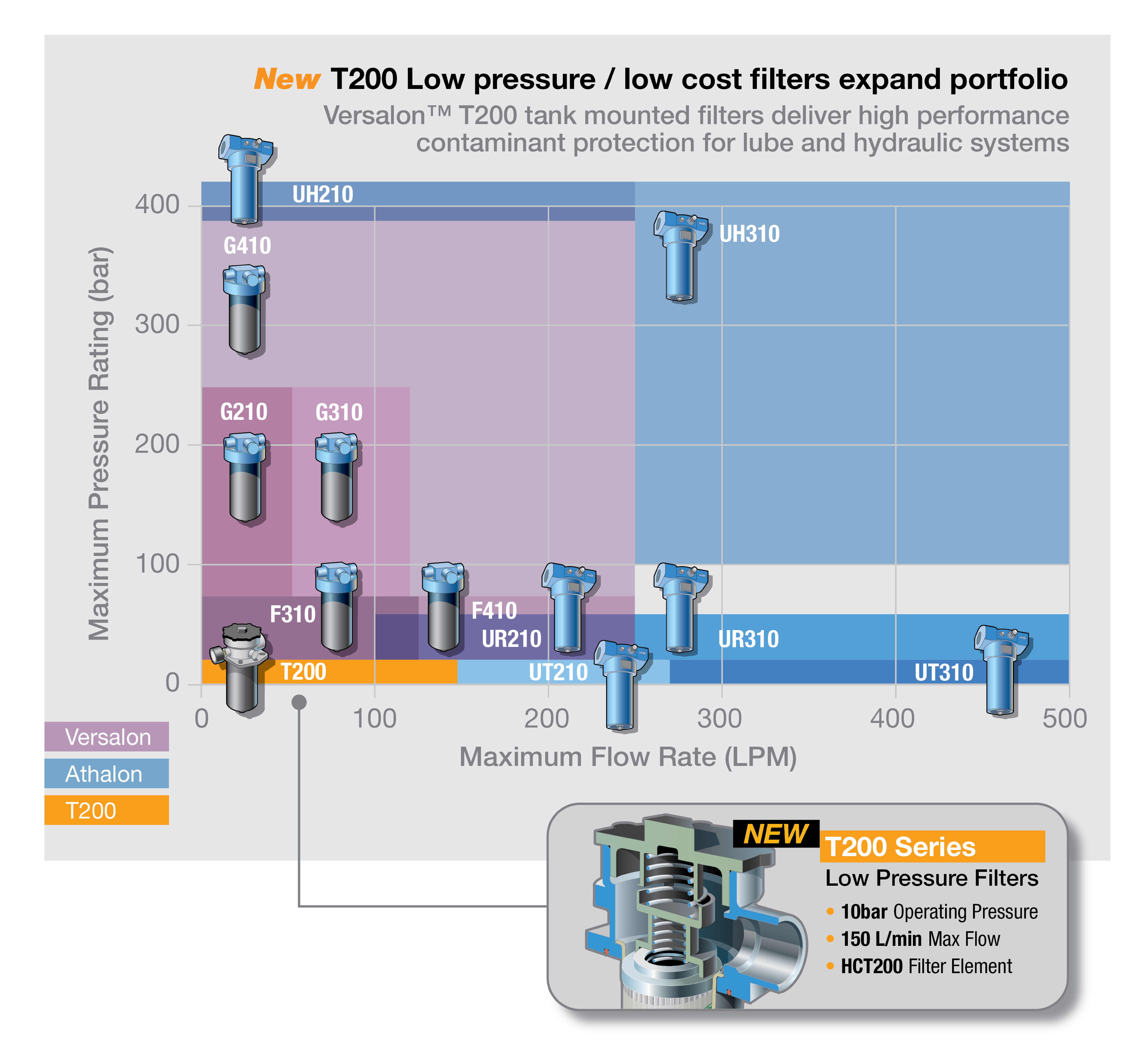

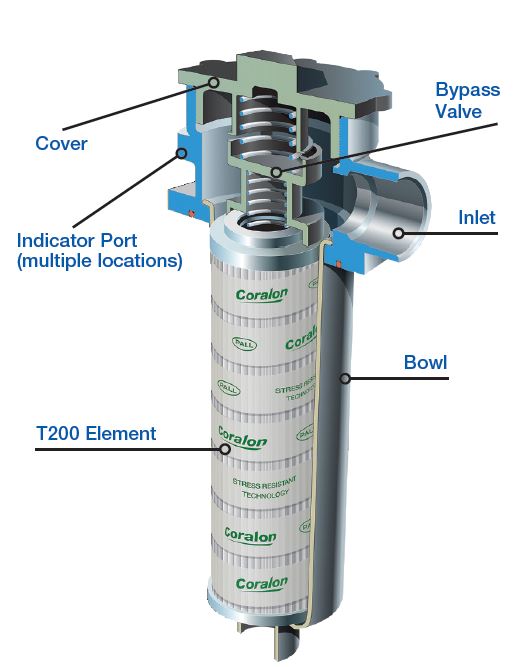

Download:Versalon™ T200 tank mounted filters deliver high-performance contaminant protection for lube and hydraulic systems in an economical package tailored for Industrial and Mobile OEMs. The T200 features Coralon® filter elements, with world-class BetaX(C)≥1000 filtration rating.

Notes and Specifications

Filter Housing

- Maximum Flow Rate (8-inch assembly):

150 L/min (39 USgpm ) - Maximum Allowable Working Pressure:

10 bar (145 psi) - Fluid Compatibility:

Compatible with all petroleum oils, water glycols, water-oil emulsions, and most synthetic hydraulic and lubrication fluids - Temperature Range:

Nitrile Seals: -29°C to 100°C (-20°F to 212°F) 50°C (122°F) maximum in HWCF or water-glycol fluids - Bypass Valve Settings:

3.4 bar (50 psi) - Visual Gauge Settings:

Visual gauge with green at <2.4 bar="" 35="" psi="" and="" red="">2.4 bar (35 psi) - Materials of Construction:

Head: Aluminum alloy

Cover: Polyamide

Canister: Polyamide

Filter Element

- Filter Element Collapse Pressure:

10 bar (145psid ) - Filter Element Construction:

Inorganic fibers impregnated and bonded with epoxy resins. Corrosion protected carbon steel core and end caps

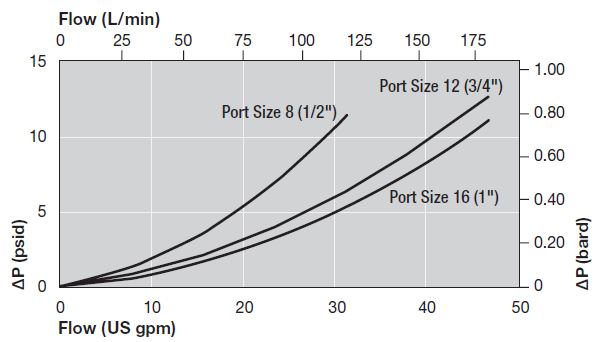

Pressure Drop Information

Housing pressure drop using fluid with 0.9 S.G.

Housing pressure drop is directly proportional to specific gravity

Element Pressure Drop

HCT200 Filter Elements – bard/1000 L/min (

| Length Code | CS | CT |

| 04 | 6.0 (0.33) | 3.92 (0.21) |

| 08 | 3.33 (0.18) | 2.04 (0.11) |

Multiply actual flow rate times factor in

Note: factors are per 1000 L/min and per 1 US

Sample ΔP calculation

T200 Series 8 inch length with C16 ports using CS grade media. Operating conditions 100 L/min flow rate using a hydraulic fluid at 45 cST and specific gravity (s.g.) 1.2

Total Filter ΔP

= ΔP housing + ΔP element= (0.32 x 1.2/0.9) bard (housing)

+ ((100 x 3.3/1000) x 45/30 x 1.2/0.9) bard (element)

= 0.43 bard (housing) + 0.66 bard (element)

= 1.09 bard (15.8 psid)

T-200_Series_2

Table 1: Housing Port Style Options

| Code | Port Style |

| C | BSP threads to ISO 228 |

| U2 | JIS B0203 tapered pipe thread |

Table 2: Housing Port Size Options

| Code | Port Size |

| 08 | 1/2” |

| 12 | 3/4” |

| 16 | 1" |

Table 3: Indicator Port Location

| Code | Gauge Position |

| 1 | Position 90 degrees counter clockwise from |

| 2 | Position 90 degrees clockwise from |

| 3 | Position opposite from inlet port |

Table 4: Filter Element Options

| Code | Rating (μm) βX(C)≥1000 |

| CS | 12 |

| CT | 22 |

Table 5: Length Options

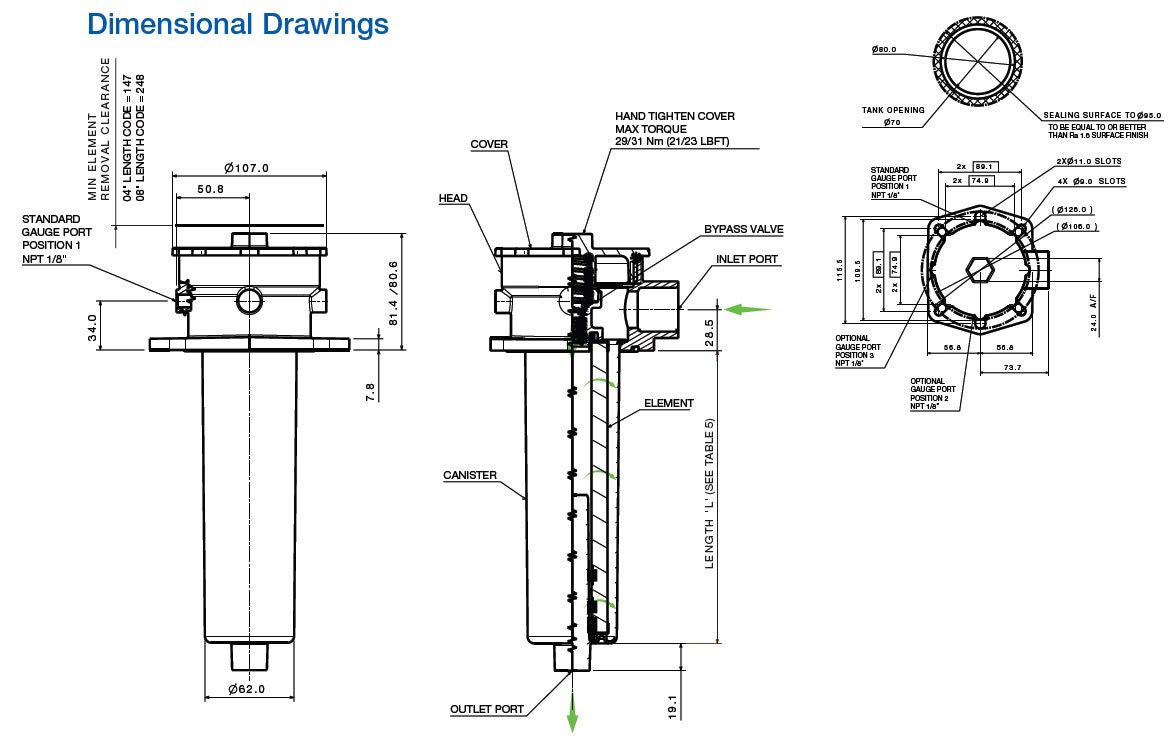

| Housing Code | Element Code | Length mm (in) |

| R | 04 | 102 (4) |

| S | 08 | 203 (8) |

Table 6: Bypass Valve

| Code | Bypass Valve Type |

| B | 3.4 ± 0.3 bar (49 ± 6 psi) |

We appreciate your review of this product. Please login to your account to leave a review.